Teiste

The operational continuity of heavy construction machinery is fundamentally linked to the resilience of its hydraulic systems. Scrúdaíonn an anailís seo na fachtóirí ríthábhachtacha a shainíonn páirteanna hiodrálacha ard-mharthanachta, moving beyond simple replacement to a more nuanced understanding of component longevity. It investigates the integral roles of material science, precision manufacturing, and system-wide compatibility in mitigating premature failure. The discussion focuses on the metallurgical properties of alloys, the distinct advantages of forging over casting, and the transformative effects of specific heat treatments. Ina theannta sin, the paper considers the symbiotic relationship between hydraulic seals and fluids, emphasizing how material selection and design directly impact performance in extreme environmental conditions. Surface engineering, including chrome plating and finishing, is presented as a crucial determinant of wear resistance. The inquiry also explores the significance of rigorous testing protocols and quality assurance certifications in verifying component integrity. I ndeireadh na dála, the argument is made that a holistic evaluation, encompassing material science, engineering tolerances, and supplier expertise, is indispensable for procuring hydraulic components that ensure both safety and long-term operational profitability.

Eochair -earraí beir leat

- Analyze material specifications; forged steel with proper heat treatment offers superior strength.

- Match seal materials like FKM or PU to your specific operating temperatures and hydraulic fluids.

- Inspect surface finishing; a low Ra value on cylinder rods is vital for extending seal life.

- Prioritize suppliers who provide certified and pressure-tested high-durability hydraulic parts.

- Déan costas iomlán na húinéireachta a mheas, not just the initial price of the components.

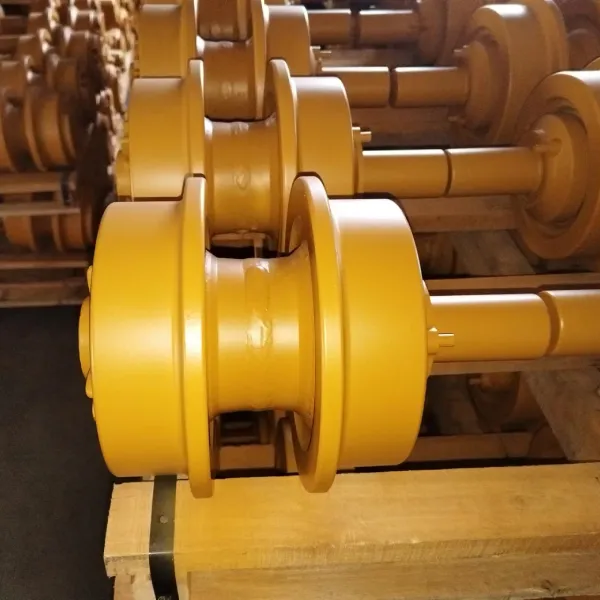

- Ensure components are designed for your specific application, from undercarriage parts to buckets.

- Confirm fluid compatibility to prevent seal degradation and system-wide contamination.

Tábla na nÁbhar

- Seiceáil 1: Deconstructing Material Science and Manufacturing Methodologies

- Seiceáil 2: Scrutinizing Seal Systems and Fluid Dynamics

- Seiceáil 3: Assessing Precision Engineering and Surface Integrity

- Seiceáil 4: Verifying Quality Assurance Through Testing and Certification

- Seiceáil 5: Evaluating Supplier Expertise and Application-Specific Solutions

- Ceisteanna coitianta (Ceisteanna CCanna)

- Conclúid

- Tagairtí

Seiceáil 1: Deconstructing Material Science and Manufacturing Methodologies

The heart of any piece of heavy machinery, from a towering excavator to a relentless dozer, is its hydraulic system. This system is the machine's muscle, converting fluid pressure into immense mechanical force. Ach fós féin, this muscle is only as strong as its constituent parts. A single failed cylinder, hose, or pump can bring a multi-million dollar operation to a standstill, costing thousands in downtime and repairs. The selection of these components, mar sin, is not a trivial matter of finding a part that fits. It is an exercise in engineering foresight. The pursuit of high-durability hydraulic parts begins not on the job site, but deep within the atomic structure of the materials themselves and the processes that shape them. To truly understand durability, one must become a student of metallurgy and manufacturing, appreciating that the difference between a part that lasts a season and one that lasts a decade is often decided before the steel is even cool.

The Primacy of Steel Alloys

Imagine you are building a shield. Would you make it from simple iron? Probably not. You would want something stronger, something that could resist bending and breaking. The same logic applies to the core components of a hydraulic system, like the cylinder barrel and rod. The base material is almost always steel, but not all steel is created equal. The specific alloy—the recipe of elements mixed with iron—determines the fundamental characteristics of the final product.

For demanding applications in construction machinery, engineers often turn to medium-carbon and alloy steels. Let's consider a common choice: 4140 steel. This is not just a random number; it's a code. The '41' indicates it's a chromium-molybdenum steel, and the '40' points to a carbon content of approximately 0.40%. Why these elements? Chromium adds hardness, friotaíocht a chaitheamh, and a degree of corrosion resistance. Molybdenum enhances toughness, which is the material's ability to absorb energy and deform without fracturing—vital for handling shock loads when a bucket hits rock.

Anois, think about the operational environment. A machine in the Siberian winter faces extreme cold, which can make steel brittle. A machine in a Middle Eastern desert must endure abrasive sand and high temperatures. For these scenarios, a more complex alloy like 4340 might be chosen. It adds nickel to the chromium-molybdenum mix. Nickel significantly improves low-temperature toughness, preventing the steel from shattering like glass when subjected to impact in freezing conditions. It also contributes to hardenability, which we will explore later. The selection of the right alloy is the first and perhaps most foundational check in the quest for high-durability hydraulic parts. It is the genetic code that dictates the potential for strength and resilience. A part made from a lesser alloy, like a simple 1020 carbon steel, might look identical but will lack the intrinsic capacity to withstand the relentless stresses of heavy-duty work.

| Material/Alloy | Key Alloying Elements | Primary Characteristics | Typical Application in Hydraulics |

|---|---|---|---|

| 1045 Cruach Carbóin | Mangainéis (Mn) | Good tensile strength, moderate hardenability. | Ginearálta-chuspóir, lower-pressure cylinder rods and pins. |

| 4140 Alloy Steel | Cróimiam (Cr), moluibdín (Mo) | High toughness, good fatigue strength, good wear resistance. | High-pressure cylinder rods, gears, high-stress shafts. |

| 4340 Alloy Steel | Nicil (Le linn), Cr, Mo | Toughness den scoth, high strength, good fatigue resistance, good low-temperature properties. | Critical components in extreme environments: aircraft landing gear, heavy-duty excavator cylinder rods. |

| Induction-Hardened Chrome-Plated (IHCP) Rod | Base steel (e.g., 1045, 4140) | Extremely hard surface layer, tough core, superior corrosion resistance. | The vast majority of modern hydraulic cylinder rods. |

| Ductile Iron (e.g., 65-45-12) | Graphite Nodules | Good machinability, excellent vibration damping, moderate strength. | Cylinder pistons, glands, end caps (where compressive strength is key). |

Gaibhniú vs. Réitigh: A Tale of Two Microstructures

Once the proper alloy is selected, how is it shaped into a cylinder cap, a rod eye, or a piston? The two most common industrial methods are casting and forging. While both can produce a part of the same shape, the internal structure they create is profoundly different, with significant implications for durability.

Casting is conceptually simple: you melt the metal and pour it into a mold. It's like making an ice cube. This process is efficient for complex shapes and is generally less expensive. ach, de réir mar a fhuaraíonn agus a dhaingníonn an miotal leáite, tá a struchtúr inmheánach gráin randamach den chuid is mó, like a pile of sand. This random arrangement can sometimes lead to microscopic voids or porosity, creating potential weak points where cracks can initiate under stress.

Gaibhniú, ar an láimh eile, is a process of controlled deformation. A solid billet of steel is heated until it is malleable and then pounded, pressed, or squeezed into shape using immense force. Think of a blacksmith hammering a horseshoe. This process does something remarkable to the metal's internal structure. It forces the grains of the steel to align with the flow of the material, following the contours of the part. This is called the "grain flow."

Why does this matter? Imagine a piece of wood. It is much harder to split along the grain than against it. The aligned grain flow in a forged part acts in a similar way, creating a component that is significantly stronger and more resistant to fatigue and impact than its cast equivalent. For critical, load-bearing hydraulic components like rod ends or cylinder bases that are subjected to high tensile and shock loads, a forged part offers a superior margin of safety and a longer service life. While a cast part might be adequate for a static component like a valve body, for the dynamic, high-stress parts of a construction machine's hydraulic system, forging provides a level of structural integrity that casting often cannot match. When evaluating high-durability hydraulic parts, asking about the manufacturing method—forged or cast—is a question that cuts to the very core of the component's expected performance.

The Art and Science of Heat Treatment

Having the right alloy and the right manufacturing process is only two-thirds of the metallurgical puzzle. An deiridh, and arguably most transformative, step is heat treatment. This is a controlled process of heating and cooling the metal to manipulate its microstructure and achieve a desired balance of mechanical properties. It is akin to tempering chocolate or firing pottery; the process itself fundamentally changes the nature of the material.

One of the most common processes for hydraulic components is "quenching and tempering." The part is first heated to a critical temperature, causing its internal crystal structure to change into a phase called austenite. Fuaraítear go tapa é ansin, nó “múchadh," i meán mar ola nó uisce. This rapid cooling traps the carbon atoms in a highly stressed, struchtúr criostail cosúil le snáthaid ar a dtugtar martensite, which is extremely hard but also very brittle. A fully quenched part is too brittle for most applications.

This is where "tempering" comes in. The brittle, as-quenched part is reheated to a lower temperature and held for a specific time. This process relieves some of the internal stresses and allows the microstructure to transform slightly, reducing hardness but significantly increasing toughness. By carefully controlling the tempering temperature, a metallurgist can dial in the perfect combination of hardness (Le haghaidh friotaíocht a chaitheamh) agus toughness (le haghaidh friotaíocht tionchair) required for a specific application.

For components like a hydraulic cylinder rod, an even more sophisticated process is often used: "case hardening," specifically induction hardening. An áit seo, only the surface of the rod is rapidly heated using electromagnetic induction. Once the surface reaches the critical temperature, it is immediately quenched. The result is a part with two personalities: an extremely hard, wear-resistant outer "case" (to resist scratching and protect the seals) and a softer, tougher inner "core" that retains the ductility and toughness needed to withstand bending and shock loads without fracturing. A properly heat-treated component is the hallmark of a high-durability hydraulic part. It represents a sophisticated balance of properties that cannot be achieved by material selection or forming alone.

Seiceáil 2: Scrutinizing Seal Systems and Fluid Dynamics

If the steel components are the bones of a hydraulic system, the seals are its ligaments and cartilage. They are the often-overlooked elements that contain the immense pressure, prevent leakage, and keep contaminants out. A hydraulic cylinder with a failed seal is no longer a tool of immense force; it is a leaky, inefficient paperweight. The integrity of the entire system hinges on these seemingly simple rings of polymer. Selecting high-durability hydraulic parts requires a deep appreciation for the complex interplay between seal materials, seal design, and the hydraulic fluid itself. This is a world of chemistry, physics, and mechanical design, where a mismatch in any one area can lead to catastrophic failure.

Beyond the Basic O-Ring: Understanding Modern Seal Materials

Not long ago, a seal was a simple rubber O-ring. Inniu, the science of polymer chemistry has given us a vast arsenal of materials, each engineered for specific challenges. Choosing the right one is paramount. Let's examine the most common players in the world of hydraulic seals.

Nitrile (NBR), often called Buna-N, has been a workhorse for decades. It offers good resistance to standard petroleum-based hydraulic fluids and has good mechanical properties. Its primary weakness is a relatively limited temperature range, typically up to about 100°C (212°F), and poor resistance to sunlight and ozone.

For higher temperature applications, such as in the engine compartment or in machinery operating in the hot climates of Australia or the Middle East, Fluoroelastomer (FKM), commonly known by its trade name Viton®, is the superior choice. FKM can handle temperatures up to 200°C (392°F) and offers excellent resistance to a wide range of chemicals, solvents, and synthetic fluids. Its trade-off is higher cost and poorer performance in very cold conditions.

For applications demanding exceptional toughness and abrasion resistance, Polyurethane (PU) is often the go-to material. Think of the seals on a hydraulic piston, which are constantly sliding against the cylinder wall. PU seals are incredibly resistant to being cut, torn, or abraded, making them ideal for high-pressure piston and rod seals. They also have an excellent ability to return to their original shape.

Ar deireadh, there is Polytetrafluoroethylene (PTFE), famous for its brand name Teflon®. PTFE's claim to fame is its incredibly low coefficient of friction—it is one of the slipperiest materials known. This makes it perfect for applications where "stick-slip" (a jerking motion at low speeds) is a problem. Because PTFE is a rigid plastic, it is often "energized" with a rubber O-ring or a metal spring to maintain its sealing force.

Understanding these materials is the first step. A supplier of high-durability hydraulic parts will not just offer a "seal kit"; they will be able to discuss the material composition and recommend the right polymer for your specific operating conditions—be it the arctic cold of a Russian winter or the searing heat of an African mine.

| Seal Material | Common Abbreviation | Operating Temperature Range | Key Strengths | Primary Weaknesses |

|---|---|---|---|---|

| Nitrile Rubber | NBR | -35°C to 100°C (-30°F to 212°F) | Excellent resistance to petroleum oils, good mechanical properties, cost-effective. | Poor resistance to ozone/weathering, moderate temperature limit. |

| Fluoroelastomer | FKM (Viton®) | -20°C to 200°C (-4°F to 392°F) | Excellent high-temperature and chemical resistance (oils, fuels, aigéid). | Higher cost, poor performance in very low temperatures. |

| Polyurethane | PU | -40°C to 100°C (-40°F to 212°F) | Exceptional abrasion and tear resistance, neart teanntachta ard. | Can be vulnerable to hydrolysis in hot water/steam. |

| Polytetrafluoroethylene | PTFE (Teflon®) | -200°C to 260°C (-328°F to 500°F) | Extremely low friction, outstanding chemical resistance, wide temperature range. | Not resilient (requires an energizer), prone to cold flow (creep). |

| Hydrogenated Nitrile | HNBR | -40°C to 150°C (-40°F to 302°F) | Better heat and chemical resistance than NBR, good mechanical strength. | More expensive than NBR. |

Seal Design for Extreme Environments

The material of the seal is only half the story. The design of the seal and the way different seals work together in a system are just as important, especially in the dirty, demanding world of construction machinery. A modern hydraulic cylinder gland doesn't use just one seal; it uses a multi-layered defense system.

At the outermost layer, you have the "wiper" or "scraper" seal. Its only job is to clean the hydraulic rod as it retracts into the cylinder. Think of it as a squeegee. It prevents dust, láib, uisce, and ice from being dragged into the cylinder, where they would act like sandpaper, destroying the other seals and contaminating the hydraulic fluid. In the sandy conditions of the Middle East or the muddy environments of Southeast Asia, a high-quality, sharp-lipped polyurethane wiper is not a luxury; it is a necessity.

Just behind the wiper is the primary "rod seal." This is the seal that does the heavy lifting of containing the high-pressure hydraulic fluid. It is often a "U-cup" seift, where the pressure of the fluid itself acts on the inner lips of the 'U', energizing it and forcing it more tightly against the rod and the housing. This clever design means that as pressure increases, the sealing force also increases.

In very high-pressure or high-shock systems, an additional seal called a "buffer seal" may be placed between the rod seal and the piston. Its job is to absorb pressure spikes that can occur during rapid cylinder movements. It protects the primary rod seal from these damaging spikes, significantly extending its life.

The combination and design of these seals—the wiper, the rod seal, the buffer seal, and the piston seals—constitute a sophisticated sealing system. When evaluating a replacement cylinder or seal kit, it is not enough to see that the seals are there. One must ask about the design. Is it a single-seal system or a multi-stage system? Is the wiper material robust enough for the environment? These design considerations are a defining characteristic of high-durability hydraulic parts.

The Hydraulic Fluid as a System Component

It is a common mistake to think of hydraulic fluid as just "oil." I ndáiríre, the fluid is arguably the most important component in the entire system. It is a multi-functional liquid marvel that must transmit power, lubricate moving parts, transfer heat, and protect components from corrosion. Critically, it must also be compatible with the seals.

The most fundamental property of a hydraulic fluid is its viscosity—its resistance to flow. This is not a single value; it changes with temperature. A good hydraulic fluid has a high "viscosity index" (VI), which means its viscosity changes relatively little as it heats up or cools down. This is vital for equipment that must operate from a cold start in Russia to full-load temperature in the Australian outback.

Modern fluids also contain a complex package of additives. Anti-wear (AW) additives form a protective film on metal surfaces to prevent scoring under high pressure. Corrosion inhibitors protect metal surfaces from water contamination. Demulsifiers help separate water from the oil, allowing it to be drained off.

The trouble arises when the fluid and the seals are not compatible. Mar shampla, using a standard NBR seal with certain types of synthetic or biodegradable hydraulic fluids can cause the seal to swell, soften, and degrade rapidly. Os a choinne sin, some aggressive fluids can cause seals to shrink and harden, as a dtagann sceitheadh. This is why it's so important to treat the fluid and seals as a single system. A reputable supplier of hydraulic components will not only provide the part but will also be able to advise on the correct fluid type and ensure that the supplied seals are fully compatible. Ignoring this symbiotic relationship is a common and costly mistake, turning a perfectly good set of high-durability hydraulic parts into a source of failure due to a simple chemical incompatibility.

Seiceáil 3: Assessing Precision Engineering and Surface Integrity

We have explored the deep, internal world of metallurgy and the chemical world of seals and fluids. Anois, we must turn our attention to the surface of things—to the realm of precision machining and finishing. In a hydraulic system operating at thousands of pounds per square inch (PSI), the quality of the surfaces that slide against one another is not a cosmetic detail. It is a fundamental aspect of performance and longevity. The difference between a smooth, long-lasting system and one that leaks and fails prematurely can be measured in micrometers (miocrón), a unit of measurement one-thousandth of a millimeter. This is the world of precision engineering, where microscopic perfection is the goal.

The Unseen World of Surface Roughness (Ra)

Imagine trying to slide a piece of silk over a sheet of sandpaper. The silk would quickly shred. Now imagine sliding that same silk over a pane of glass. It would glide effortlessly for a very long time. This is a perfect analogy for the relationship between a hydraulic seal and the surface of the cylinder rod it slides on.

The surface of a steel rod, even one that looks perfectly smooth to the naked eye, is actually a landscape of microscopic peaks and valleys. The average height of these irregularities is measured and expressed as a "surface roughness" value, most commonly "Ra." A lower Ra value signifies a smoother surface.

For a hydraulic cylinder rod, this is not a trivial specification. A rod with a high Ra value (a rough surface) will act like a file, continuously abrading the soft lip of the rod seal with every stroke of the cylinder. This will rapidly wear out the seal, as a dtagann sceitheadh. The microscopic valleys can also carry a thin film of oil past the seal on the extension stroke and then drag tiny particles of contamination back into the cylinder on the retraction stroke.

Os a choinne sin, a surface that is too smooth (an extremely low Ra value) can also be a problem. It can prevent a sufficient lubricating film of oil from being maintained between the seal and the rod, leading to high friction, heat generation, and a phenomenon called "stick-slip," where the seal chatters and jumps instead of sliding smoothly.

Dá bhrí sin, there is an optimal range of surface finish for a hydraulic rod—smooth enough to prevent seal abrasion but with just enough of a pattern to retain a lubricating film. A manufacturer of high-durability hydraulic parts pays obsessive attention to achieving this specific Ra value through processes like grinding and polishing. When inspecting a potential replacement part, inquiring about the Ra value of the rod finish is a sign of a knowledgeable buyer. It demonstrates an understanding that durability lies not just in what you can see, but also in the microscopic details you cannot.

The Role of Hard Chrome Plating

Most hydraulic cylinder rods have a shiny, mirror-like finish. This is not just polished steel; it is a layer of hard chrome plating. This plating serves several vital functions that are indispensable for a long service life.

First and foremost, it provides an incredibly hard surface. Hard chrome plating typically has a hardness in the range of 66 chuig 70 on the Rockwell C scale (HAD). To put that in perspective, a high-quality file is around 65 HAD. This extreme hardness makes the rod highly resistant to scratches, dents, and abrasion from external sources. A small scratch or nick on an unplated rod can create a sharp edge that will instantly slice and destroy a seal. The hard chrome layer acts as a suit of armor, protecting the critical surface finish underneath.

Dara, the chrome layer is highly corrosion-resistant. A bare steel rod would quickly rust when exposed to moisture, especially in the humid climates of Southeast Asia or in marine applications. Rust pits create a rough, abrasive surface that would function like a cheese grater on the seals. The dense, non-porous layer of chrome provides a robust barrier against corrosion.

The quality of the plating process is paramount. A poorly applied chrome layer can chip, flake, or peel off under stress or impact. This is often worse than having no plating at all, as the sharp edges of the flaking chrome will shred the seals in short order. The thickness of the chrome is also important. A thicker layer generally provides better corrosion protection and allows for minor scratches to be polished out without exposing the base metal. When sourcing a cylinder or rod, asking about the chrome plating process and its thickness is a key part of due diligence in the search for genuine high-durability hydraulic parts.

Tolerances and Clearances: A Game of Micrometers

The final piece of the precision puzzle is the concept of "tolerances" and "clearances." In a perfect world, a piston with a 100mm diameter would fit perfectly into a cylinder bore that is also exactly 100mm. But in the real world of manufacturing, achieving exact dimensions is impossible. In ionad, engineers specify a "tolerance"—an acceptable range of variation. The piston might be specified as 100mm ±0.05mm, meaning any piston between 99.95mm and 100.05mm is acceptable.

The "clearance" is the intentional gap between two moving parts. Mar shampla, the gap between the outside diameter of the piston and the inside diameter of thecylinder bore. This gap is critical. If it is too large, a significant amount of high-pressure fluid can leak past the piston from one side to the other. This is called "internal leakage" or "blow-by." It results in a loss of power, reduced efficiency, and the generation of excess heat as the fluid is forced through the small gap. The cylinder will drift under load and will be slow and weak.

If the clearance is too small, there is no room for a lubricating film of oil between the parts. This leads to metal-to-metal contact, galling (a form of wear caused by adhesion between sliding surfaces), and eventual seizure of the component. The thermal expansion of the metal as it heats up during operation must also be accounted for; a clearance that is adequate when cold might disappear when the system reaches operating temperature.

Achieving the correct clearances requires incredibly precise machining of both the piston and the cylinder bore. This is why manufacturers of high-quality components use sophisticated machinery like CNC (Computer Numerical Control) lathes and honing machines. Honing is a specific finishing process for the inside of the cylinder bore that produces a very precise diameter and a characteristic cross-hatch pattern on the surface, which is ideal for retaining lubricating oil. The ability to consistently hold tight tolerances, on the order of a few hundredths of a millimeter, is a non-negotiable requirement for any supplier of high-durability hydraulic parts. It is this microscopic precision that ensures the hydraulic system operates at peak efficiency and enjoys a long, productive life.

Seiceáil 4: Verifying Quality Assurance Through Testing and Certification

A supplier can make many claims about their materials, manufacturing processes, and precision engineering. They can speak of forged steel, advanced seal materials, and microscopic tolerances. But how can a buyer be confident that these claims are true for the specific part they are about to purchase? This is where the domain of quality assurance, testing, and certification becomes indispensable. These processes provide objective, verifiable proof of quality. They are the mechanisms of trust that separate a reputable manufacturer from a mere reseller. For anyone serious about procuring high-durability hydraulic parts, understanding what happens in the quality control lab is just as important as understanding what happens in the foundry.

Beyond the Visual Inspection: Tástáil Neamh-Mhillteach (NDT)

Many of the most dangerous defects in a metal component are invisible to the naked eye. They can be internal flaws from the casting process or microscopic surface cracks that formed during forging or heat treatment. These tiny imperfections can act as "stress risers," points where stress concentrates. Under the cyclic loading of a hydraulic system, a crack can slowly grow from these points until the component fails suddenly and catastrophically.

To find these hidden dangers without destroying the part, manufacturers employ a range of techniques known as Non-Destructive Testing (NDT). One common method is Tástáil Ultrasonach (UT). A probe sends high-frequency sound waves into the component. Téann an fhuaim tríd an ábhar agus léiríonn sé as an mballa cúil. If there is an internal flaw like a void or an inclusion, the sound will reflect off it prematurely, creating a distinct signal on the operator's screen. It's like a form of medical ultrasound for steel parts. This is particularly important for verifying the integrity of forged components or thick-walled cylinder barrels.

Another vital technique is Cigireacht Cháithníní Maighnéadacha (MPI). This method is used to find surface and near-surface cracks in ferromagnetic materials like steel. Tá an chuid maighnéadaithe, and a fluid containing fine iron particles is applied to the surface. If there is a crack, cuirfidh sé isteach ar an réimse maighnéadach, causing the magnetic flux to "leak" out of the surface. This leakage flux attracts the iron particles, creating a visible indication directly over the crack. It is an incredibly effective way to find fatigue cracks that are too small to be seen otherwise.

For non-magnetic materials or for finding surface-breaking defects, Dye Penetrant Testing (DPT) is used. A brightly colored liquid dye is applied to the surface and allowed to seep into any open cracks. After the excess dye is cleaned off, a white developer is applied. The developer acts like a blotter, drawing the trapped dye out of the cracks and making them clearly visible against the white background.

A manufacturer that invests in and routinely uses these NDT methods is demonstrating a serious commitment to quality. They are actively hunting for flaws before a part ever leaves the factory. When sourcing critical components, asking for NDT reports is a powerful way to ensure you are getting a verified, high-durability hydraulic part.

The Gauntlet of Performance Testing

Finding flaws is one thing; proving performance is another. The ultimate test of a hydraulic component is to subject it to the pressures and cycles it will see in the real world—and then some. This is the purpose of performance testing.

The most fundamental test is a hydrostatic pressure test. Every hydraulic cylinder produced by a quality manufacturer should be subjected to this test. The cylinder is filled with hydraulic fluid, all air is bled out, and the pressure is raised to a "proof pressure," which is typically 1.5 chuig 2.0 times the cylinder's maximum rated working pressure. The cylinder is then held at this pressure for a set period, and inspectors look for any signs of external leakage from seals or welds, or any yielding or permanent deformation of the cylinder body. This test provides a 100% guarantee that the cylinder will not fail under its normal operating parameters.

For new designs or to validate a manufacturing process, an even more punishing test is employed: impulse or fatigue testing. In this test, a cylinder is put on a specialized test rig that subjects it to rapid pressure cycles, from near zero to full working pressure, over and over again. The goal is to simulate a lifetime of work in a compressed timeframe. A cylinder might be subjected to a million or more cycles to see how its welds, rónta, and structural components hold up to the repeated stress. This is how engineers find potential weak points and validate the fatigue life of their designs. A supplier who can provide data from fatigue testing is offering more than just a part; they are offering a component whose long-term performance has been scientifically proven. Exploring a comprehensive catalog of páirteanna undercarriage from such a supplier gives you confidence in the engineering behind every component.

Decoding Certifications: What ISO 9001 Really Means

I margadh domhanda, buyers often rely on third-party certifications to gauge a supplier's commitment to quality. The most widely recognized of these is Iso 9001. It is common to see this certification displayed on a company's website or literature, but what does it actually signify?

It is important to understand that ISO 9001 is not a product certification. It does not state that a specific hydraulic cylinder is "good." In ionad, it is a certification of a company's Quality Management System (QMS). To become ISO 9001 deimhnithe, a company must demonstrate to an external auditor that it has robust, documented processes for everything that affects quality. This includes things like:

- How they control documents and records.

- How they select and evaluate their own suppliers.

- How they identify and trace products throughout the manufacturing process.

- How they calibrate their inspection and testing equipment.

- How they handle non-conforming products.

- How they analyze customer feedback and implement corrective actions.

Go bunúsach, Iso 9001 certification provides assurance that a company is not achieving quality by accident. It shows they have a systematic, repeatable approach to ensuring their products meet customer and regulatory requirements. It implies a culture of continuous improvement and accountability. While it is not a direct guarantee of a flawless part, it is a very strong indicator that you are dealing with a professional, organized, and quality-conscious manufacturer. It is a foundational element of trust in the complex process of sourcing high-durability hydraulic parts from a global supply chain.

Seiceáil 5: Evaluating Supplier Expertise and Application-Specific Solutions

The final check in our comprehensive guide moves from the tangible aspects of the part itself—the metal, the seals, the finish—to the intangible but equally important qualities of the supplier. In the modern world of heavy equipment, you are not merely buying a piece of steel; you are entering into a partnership. The right supplier acts as a consultant, a problem-solver, and a long-term resource. The wrong supplier is simply a transactional vendor. Distinguishing between the two is critical for ensuring the long-term reliability and profitability of your machinery. The selection of a supplier for high-durability hydraulic parts should be approached with the same rigor as the technical evaluation of the components they sell.

The Value of Proven Performance: Case Studies and Testimonials

Theory is one thing; real-world performance is another. A hydraulic part that performs flawlessly in a controlled lab environment may fail quickly when exposed to the shock loads, contamination, and temperature extremes of a construction site in Africa or a mine in Australia. This is why evidence of proven performance is so valuable.

A reputable supplier, proud of their products' marthanacht, will be able to provide you with more than just a spec sheet. They should have a portfolio of cás-staidéir. These are detailed accounts of how their components have been used by other customers in specific applications. A good case study will outline the challenge the customer was facing (e.g., frequent cylinder failures on a rock breaker), the solution provided (e.g., a cylinder with a forged rod eye, induction-hardened rod, and a specialized seal package), and the results (e.g., a 300% increase in service life and a significant reduction in downtime).

Mar an gcéanna, look for detailed testimonials from customers in industries and regions similar to your own. A glowing review from a demolition contractor in Korea gives you confidence that the parts can handle high-cycle, high-shock work. A testimonial from a mining company in Russia's Far East suggests the seals and steel will perform in extreme cold. This type of real-world validation is often more telling than any technical data sheet. It serves as a powerful de-risking tool, giving you confidence that you are not the first to test these components in a demanding environment.

Engineering Support and Customization

The needs of heavy machinery are not always "off-the-shelf." An older machine may require a part that is no longer made. A unique attachment, like a specialized ripper or grapple, might demand a custom-designed hydraulic cylinder. Or perhaps you are facing a recurring failure and need an engineered solution, not just another standard replacement part. This is where the true expertise of a supplier shines through.

A top-tier supplier has an accessible engineering team. They are not just order-takers; they are problem-solvers. You should be able to have a technical conversation with them. Can they look at a failed part and offer a credible failure analysis? Can they recommend a different seal material to cope with a non-standard hydraulic fluid you are using? Can they design and manufacture a cylinder with custom mounting points or a longer stroke length?

This capability for customization and technical support is a hallmark of a true manufacturing partner. It indicates a deep understanding of hydraulic principles and applications, not just part numbers in a catalog. Whether you need a standard replacement or a fully bespoke solution, having access to this engineering expertise is an invaluable resource. When you can work with a supplier to develop a high-performance excavator bucket and the cylinders to power it, you are moving beyond simple purchasing and into a collaborative relationship that enhances your operational capability.

The Total Cost of Ownership (TCO) Mindset

Perhaps the most significant mental shift for a professional buyer is moving from a focus on purchase price to a focus on Total Cost of Ownership (TCO). TCO is a financial estimate intended to help buyers determine the direct and indirect costs of a product or system. For a hydraulic component, the initial purchase price is often one of the smallest parts of its total cost.

Consider two hydraulic cylinders. Cylinder A costs $800. Cylinder B, a high-durability model, costs $1,200. The temptation is to save $400 and buy Cylinder A. But let's look at the TCO.

Cylinder A fails after 2,000 uair an chloig. The failure causes an unscheduled stop, leading to 8 uaireanta downtime. The cost of this downtime (idle operator, stalled project, potential penalties) tá $200 in aghaidh na huaire, for a total of $1,600. The labor to remove the failed cylinder and install a new one takes two mechanics 4 hours each, ag $75 in aghaidh na huaire, for a cost of $600. Dá réir sin, the total cost associated with Cylinder A's failure is $800 (chuid) + $1,600 (downtime) + $600 (labor) = $3,000.

Cylinder B, with its forged components, superior seals, and robust design, lasts for 6,000 hours—three times as long. Over that 6,000-hour period, you would have used three of Cylinder A, for a total cost of 3 x $3,000 = $9,000. The total cost of Cylinder B over that same period is its initial purchase price of $1,200 plus the cost of one planned replacement, for a total of roughly $1,200 + $600 (labor) = $1,800.

In this realistic scenario, the "cheaper" part actually cost five times more.

Adopting a TCO mindset fundamentally changes the purchasing decision. It frames the acquisition of high-durability hydraulic parts not as an expense, but as a strategic investment in uptime, táirgiúlacht, and profitability. A good supplier understands this concept and will help you analyze the long-term value of their products, rather than just competing on the initial price tag. They sell reliability, not just replacement parts.

Ceisteanna coitianta (Ceisteanna CCanna)

What are the most common signs of a failing hydraulic cylinder? The most common indicators include external fluid leaks around the rod seal or end caps, a cylinder that "drifts" or won't hold its position under load (indicating internal piston seal leakage), a noticeable loss of power or speed, and jerky or erratic movement. A bent or scored cylinder rod is also a clear sign of serious trouble.

How does extreme cold or heat affect hydraulic parts? Extreme cold, such as in Russia, can make steel components brittle and more susceptible to fracture from impact. It also causes seals to stiffen and lose their flexibility, as a dtagann sceitheadh. Extreme heat, common in the Middle East and Australia, accelerates the degradation of hydraulic fluid and can cause seals to soften, swell, or become brittle, as a dtagann teip roimh am.

Is it better to repair or replace a damaged hydraulic cylinder? The decision depends on the extent of the damage and the cost. If the cylinder barrel is not scored, the rod is not bent, and the other structural components are sound, a simple reseal is often cost-effective. ach, if the rod is bent, the chrome is badly damaged, or the inside of the barrel is scored, the cost of repair (new rod, re-chroming, honing the barrel) can often approach or exceed the cost of a new, high-quality replacement cylinder.

What is the single most important maintenance task for hydraulic system longevity? Keeping the hydraulic fluid clean and at the proper level is by far the most critical maintenance task. Contaminated fluid acts as a liquid abrasive, accelerating wear on every component in the system, from pumps to seals to valves. Regular filter changes and periodic fluid analysis are essential investments in the health of your construction machinery.

Why do some replacement parts fail so much faster than the original OEM parts? This often comes down to the factors discussed in this guide. Aftermarket manufacturers may cut costs by using inferior materials (e.g., cast instead of forged components), cheaper seal materials with lower temperature ratings, thinner chrome plating, or by skipping critical heat treatment or quality control testing steps. A true high-durability replacement part should meet or exceed the original equipment manufacturer's (OEM) Sonraíochtaí Sonraíochtaí.

How can I tell if a supplier is selling genuine high-durability parts? Look for suppliers who are transparent about their manufacturing processes. They should be able to discuss material grades, heat treatment methods, and seal compounds. Ask for evidence of quality control, such as pressure testing reports or ISO 9001 deimhniú. A reputable supplier sells on engineering value and proven performance, not just on price.

Can using the wrong hydraulic fluid damage my machine's components? Absolutely. Using a fluid with the wrong viscosity can lead to poor lubrication and overheating. Níos tábhachtaí fós, chemical incompatibility between the fluid and the system's seals can cause seals to swell, shrink, or dissolve, leading to massive leaks and system failure. Always use a fluid that meets the specifications provided by the machine and component manufacturers.

Conclúid

The journey through the world of high-durability hydraulic parts reveals a landscape where macroscopic force is governed by microscopic details. The resilience of a massive excavator's arm is not a matter of chance, but a direct consequence of deliberate choices made long before the component reaches the field. It begins with the elemental recipe of its steel alloy and the forging process that aligns its very grain for strength. It continues in the transformative fire of heat treatment, which bestows a dual personality of surface hardness and core toughness. The integrity of the system is then entrusted to the sophisticated chemistry of its polymer seals and the careful engineering of their design, a defense system against both immense internal pressure and external contamination. The perfection of its performance is polished to a mirror finish on a chrome-plated rod, where smoothness is measured in millionths of a meter. This physical excellence is then validated through the rigorous scrutiny of non-destructive testing and the punishing gauntlet of pressure cycling.

I ndeireadh na dála, the procurement of these vital components transcends a simple transaction. It becomes an exercise in appreciating the total cost of ownership, recognizing that the initial price is but a down payment on a part's true lifetime cost. Choosing a knowledgeable supplier who provides engineering support, proven case studies, and a commitment to quality certified by international standards is as crucial as selecting the correct material. To invest in high-durability hydraulic parts is to invest in operational uptime, project certainty, and long-term profitability. It is the recognition that in the demanding world of heavy machinery, strength is a science, and reliability is an engineered outcome.

Tagairtí

American Society for Metals. (1991). ASM handbook, volume 4: Heat treating. ASM International.

Budinski, K. G., & Budinski, M. K. (2018). Engineering materials: Properties and selection (10ú eag.). Pearson.

Fitch, J. C. (2012). The practical handbook of machinery lubrication (4ú eag.). Noria Corporation.

Flitney, R. (2014). Seals and sealing handbook (6ú eag.). Butterworth-Heinemann.

Manring, N. D., & Fales, R. C. (2019). Hydraulic control systems (2nd ed.). John Wiley & Sons.

Norton, R. L. (2020). Machine design: An integrated approach (6ú eag.). Pearson.

Stachowiak, G. W., & Batchelor, A. Thiar. (2013). Engineering tribology (4ú eag.). Butterworth-Heinemann.

Totten, G. O. (Ed.). (2006). Hydraulic fluids: A guide to selection, test methods, and use. ASTM International.