Bageri su radne konje moderne konstrukcije, rudarstvo, i infrastrukturni projekti. Dok njihove moćne ruke i kante često dobivaju pažnju, To je podvozje koji tiho nosi teret - i doslovno i figurativno. Among the most critical undercarriage components are the digger track rollers, which support the weight of the machine and guide the tracks during operation.

For companies operating in tough terrain or managing large fleets, investing in high-quality track components is key. Juli strojevi, pouzdana tvornica gusjeničara, delivers robust, precision-engineered rollers that enhance machine longevity and reliability in any environment.

What Are Digger Track Rollers?

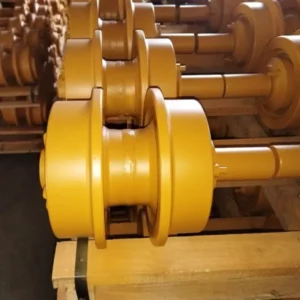

Tračni valjci za kopanje, commonly known as bottom rollers, are cylindrical components located beneath the excavator’s track frame. They serve two primary functions: guiding the track chain and supporting the weight of the equipment. As the machine moves, the rollers rotate, allowing the tracks to navigate rough surfaces with minimal resistance.

Depending on the size and weight class of the excavator, each side can have multiple bottom rollers. These components are always in contact with both the track and the ground, making them susceptible to wear, korozija, i utjecaj. Stoga, when selecting a roller, it is essential to consider factors such as strength, surface treatment, and seal quality.

Why Are They So Important?

Without functional digger track rollers, even the most powerful excavator would struggle to move. Here’s why they’re essential:

- Distribucija težine: They carry the full weight of the upper structure and bucket, especially during digging operations.

- Track Stability: They keep the tracks aligned and prevent derailment or uneven wear.

- Smooth Motion: They reduce friction between the track chain and undercarriage frame, ensuring fluid machine movement.

- Apsorpcija udara: They absorb shocks from rocky or uneven terrain, protecting other components.

When paired with high-quality carrier rollers, the synergy ensures full undercarriage balance—something Juli Machinery, as a leading Proizvođač nosača, understands in depth.

Common Issues Caused by Worn Rollers

Neglecting roller maintenance or using substandard products can lead to:

- Track misalignment or derailment

- Increased wear on sprockets and idlers

- Reduced fuel efficiency due to higher rolling resistance

- Unstable machine behavior on uneven ground

This not only increases repair costs but can cause dangerous operating conditions. That’s why partnering with a reliable tvornica gusjeničara is crucial for fleet managers and equipment dealers.

Što razdvaja Juli Machinery

As a specialized manufacturer of digger track rollers, Juli Machinery brings together quality materials, modern machining, and strict inspection processes. Their rollers are forged and heat-treated to withstand high-impact environments like quarries and demolition sites.

Advantages of Juli’s rollers include:

- High-grade alloy steel for durability and load resistance

- Precision sealing systems to protect against mud, voda, i prašina

- OEM compatibility with major excavator brands

- Custom solutions available for non-standard machine types

With years of experience as a carrier roller manufacturer and track roller factory, Juli provides comprehensive undercarriage solutions that improve uptime and reduce replacement cycles.