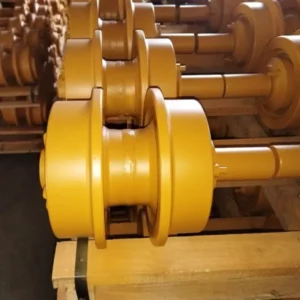

Ketika datang ke prestasi jentera berat, bahagian bawah perkahwinan seperti penggelek trek membuat perbezaan kritikal. Komponen ini membawa berat penuh mesin sambil membimbing trek semasa gerakan. Namun begitu, not all track roller factories produce components of equal durability and precision. Choosing the right supplier requires more than checking a spec sheet—it involves understanding materials, engineering processes, and compatibility with major brands such as Kubota excavator parts and Komatsu dozer parts. That’s where Juli Machinery stands out.

Why the Factory Behind the Roller Matters

Track rollers endure extreme pressure, pakai, and environmental stress. If made poorly, they wear quickly, leading to higher maintenance costs, machine instability, and even downtime. Quality is determined at the source—the factory.

Here’s what sets reliable Trek kilang roller berpisah:

- Advanced forging and heat treatment processes

- High-load-bearing design tolerance

- Precise dimensional control for OEM compatibility

- Corrosion and impact-resistant materials

- Proven performance through testing and validation

These are not optional features—they’re essential to ensure safety and operational efficiency.

What to Evaluate in a Track Roller Factory

| Evaluation Factor | Why It Matters | Juli Machinery Advantage |

|---|---|---|

| Kualiti Bahan | Determines lifespan under heavy load | Uses high-grade alloy steel with surface hardening |

| Compatibility with OEM Parts | Needed for seamless fit in Kubota or Komatsu machines | Supports major brands like Kubota excavator parts |

| Production Automation | Ensures consistency and faster delivery | Modern CNC and robotic assembly lines |

| Factory Testing Protocols | Avoids early wear, failure under stress | 100% inspection with load simulation tests |

| Customization Capabilities | Matches specific terrain and usage needs | Offers OEM/ODM services with rapid prototyping |

A true track roller factory is not just a producer but a partner in your machine’s performance. Juli Machinery leverages over a decade of manufacturing expertise to deliver rollers that meet demanding operational environments—whether it’s construction, pertanian, or mining.

Supporting Multiple Brands with Precision

One of the most important aspects for buyers is finding components that are truly compatible with leading machinery. Many cheap parts claim to “fit,” but improper tolerances can result in uneven wear and track misalignment.

Juli Machinery provides precision rollers for:

- Kubota excavator parts: Reliable for compact to mid-size excavators, maintaining smooth track movement

- Komatsu dozer parts: Built to handle high ground pressure and abrasive conditions in heavy-duty bulldozing

These rollers are designed with brand-specific geometry, ensuring frictionless movement and extending the life of the entire undercarriage system.

Trusting Juli Machinery for Track Roller Excellence

As a specialized manufacturer among top-tier track roller factories, Juli Machinery has built a reputation on engineering accuracy, material integrity, and fast fulfillment. The company not only supplies parts but also provides technical support to help customers choose the right roller for their machinery model and operating environment.

Whether you’re sourcing a fleet of Komatsu dozers or maintaining a few Kubota excavators, Juli delivers consistent quality and dependable service.

Your Undercarriage Deserves More Than Generic Parts

Cutting corners with subpar rollers means more downtime, more repairs, dan akhirnya, more cost. Choose a manufacturer like Juli Machinery—a factory that understands both the technical and operational requirements of Kubota bahagian jengkaut, Komatsu dozer parts, and the broader OEM ecosystem.

Contact Juli today to ensure your machinery performs as powerfully as it was built to.