خلاصة

The selection of a mini excavator parts manufacturer represents a significant strategic decision for fleet managers and owner-operators, مع الآثار المباشرة لوقت التشغيل التشغيلي, الربحية على المدى الطويل, وسلامة موقع العمل. This document examines the multifaceted process of vetting and choosing a supplier for critical components such as undercarriage parts, دلاء, كسارات, والأزاميل. It moves beyond superficial cost analysis to propose a structured, seven-question framework designed to probe a manufacturer's core competencies. The inquiry delves into the nuanced domains of material science and metallurgy, the rigor of manufacturing and quality control systems, and the depth of research and development capabilities. It further explores the practicalities of part compatibility, the complexities of global supply chain logistics, the verification of performance claims through empirical evidence, والطبيعة التي لا غنى عنها للدعم الفني القوي لما بعد البيع. من خلال معالجة هذه المجالات بشكل منهجي, يمكن للمشترين تطوير فهم شامل للمورد المحتمل, وتمكينهم من إقامة شراكات من شأنها تعزيز عمر الماكينة وتقديم قيمة مستدامة في بيئات تشغيلية متنوعة ومتطلبة في جميع أنحاء العالم.

الوجبات الرئيسية

- Evaluate a manufacturer's metallurgical expertise and material sourcing transparency.

- تدقيق بروتوكولات مراقبة الجودة من المواد الخام إلى التفتيش النهائي.

- Assess a supplier's commitment to research, تطوير, وابتكار المنتجات.

- تحقق من الطرق المستخدمة لضمان توافق الأجزاء والتركيب الدقيق.

- اختر شركة تصنيع قطع غيار حفارة مصغرة مع استراتيجية لوجستية عالمية قوية.

- طلب دليلًا تجريبيًا على الأداء من خلال دراسات الحالة والشهادات الإقليمية.

- إعطاء الأولوية للشركاء الذين يقدمون الدعم الفني الشامل والضمانات العادلة.

جدول المحتويات

- 1. ما هي مصادرك المادية والخبرة المعدنية?

- 2. هل يمكنك تفصيل عمليات التصنيع الخاصة بك وبروتوكولات مراقبة الجودة?

- 3. ما هو نطاق بحثك, تطوير, والقدرات الهندسية?

- 4. كيف يمكنك ضمان توافق جزء وتركيب عبر علامات تجارية ونماذج مختلفة?

- 5. ما هي استراتيجية لوجستية وسلسلة التوريد العالمية الخاصة بك, خاصة بالنسبة لمنطقي?

- 6. هل يمكنك تقديم دليل على الأداء والمتانة من خلال دراسات الحالة والشهادات?

- 7. ما هو مستوى دعم ما بعد البيع والخبرة التقنية التي تقدمها?

- الأسئلة المتداولة (التعليمات)

- خاتمة

- مراجع

1. ما هي مصادرك المادية والخبرة المعدنية?

يجب أن تبدأ المحادثة مع أي الشركة المصنعة لقطع غيار الحفارة المصغرة المحتملة بالسعر, ولكن مع مادة المكونات نفسها: الصلب. متانة دلو, مرونة الصار, وعمر الهيكل السفلي ليس من المهم الصدفة; إنها نتائج مباشرة لخيارات متعمدة تم إجراؤها قبل وقت طويل من اللحام أو القطع. للاستفسار عن مصادر المواد هو الاستفسار عن الفلسفة التأسيسية للشركة المصنعة. هل هم بناء طول العمر, أم أنها مجرد تجميع إلى نقطة سعر? يكشف هذا السؤال عن طابع المورد ويوفر الأول, مؤشر قول الجودة الذي يمكنك توقعه. تعتبر طلاقة الشركة المصنعة في لغة المعادن انعكاسًا مباشرًا لالتزامهم بسلاسة منتجاتها و, بالامتداد, لنجاح عملياتك.

الأهمية الأساسية للمواد الخام

تخيل اثنين من روابط المسار متطابقة. واحد مزور من الكربون العالي, الفولاذ الفولاذ. الآخر مصنوع من عام, الفولاذ الكربوني السفلي. للعين المجردة, لا يمكن تمييزها. حتى الآن, في الكاشطة, بيئة عالية التأثير لموقع البناء, مصائرهم مختلفة اختلافا كبيرا. قد يتحمل الأول آلاف الساعات من الخدمة, في حين أن الثانية قد تفشل قبل الأوان, تسبب التوقف الكارثي. هذا هو السبب في أن مناقشة المواد الخام ذات أهمية قصوى.

يجب أن نفهم أولاً أن "الصلب" ليس متراصة. إنها عائلة من السبائك, كل مع وصفة محددة من الحديد, الكربون, والعناصر الأخرى المصممة لإعطاء خصائص معينة. لمكونات آلات البناء, أكثر الخصائص المرغوبة هي صلابة, صلابة, وارتداء المقاومة.

صلابة هي قدرة المادة على مقاومة المسافة البادئة السطحية والتآكل. لأجزاء مثل الحواف قطع الجرافات والأسنان, التي على اتصال مستمر بمواد كاشطة مثل الرمال, الحصى, والصخرة, صلابة السطح العالية غير قابلة للتفاوض. غالبًا ما يتم تحقيق ذلك باستخدام فولاذ مع محتوى أعلى للكربون وسبائك محددة مثل الكروم والموليبدينوم, التي تتعرض بعد ذلك للمعالجة الحرارية.

صلابة is the material's ability to absorb energy and deform without fracturing. فكر في ساق الصارار الذي يواجه صخرة خفية. مادة هشة, لكن المواد الصعبة سوف تمتص الصدمة. غالبًا ما يكون هناك مفاضلة بين الصلابة والصلابة; يمكن أن تكون مادة صلبة للغاية هشة. يكمن فن المعادن في إيجاد التوازن الأمثل لكل تطبيق محدد. للمكونات الهيكلية, غالبًا ما يتم تحديد أولوية المتانة على صلابة شديد.

ارتداء المقاومة هي القدرة الأوسع على مقاومة فقدان المواد من العمل الميكانيكي. إنها وظيفة صلابة, صلابة, and the material's microstructure. يعد Boron Steel خيارًا شائعًا لأدوات التجميع الأرضية وأجزاء الهيكل السفلي لهذا السبب بالذات. إضافة كمية ضئيلة من البورون (أقل من 0.001%) يمكن أن تزيد بشكل كبير من صلابة الصلب, السماح بتحقيق صلابة عميقة وموحدة أثناء المعالجة الحرارية, وهو ما يترجم مباشرة إلى حياة أطول (مخيف & Donertas, 2017).

عندما تتعامل مع شركة تصنيع قطع غيار حفارة صغيرة محتملة, your questions should be specific. Do not accept "high-quality steel" as an answer. Ask for the specific steel grades used for their buckets, their track shoes, and their idlers. Ask why that particular grade was chosen. A knowledgeable supplier will be able to explain their rationale, connecting the properties of the steel (على سبيل المثال, the carbon content, the presence of manganese or boron) to the functional demands of the part. This level of transparency is the first sign of a trustworthy partner.

Understanding Metallurgy in Component Manufacturing

Sourcing the right raw material is only the first chapter of the story. The subsequent transformation of that raw steel into a durable, reliable component is a narrative of heat, pressure, and precision. This is the realm of metallurgy in practice, encompassing processes like forging, صب, والمعالجة الحرارية. إن فهم أساسيات هذه التقنيات يمكّنك من طرح أسئلة أكثر ثاقبة وتمييز الشركة المصنعة التي تركز على الجودة عن الشركة المصنعة التي تركز على الحجم.

دعونا نفكر تزوير. تخيل أن حدادًا يطرق قطعة من الحديد الساخن. هذا هو تزوير في شكله الأكثر عنصرية. في التصنيع الحديث, تعمل المكابس أو المطارق الضخمة على تشكيل الفولاذ إلى الشكل المطلوب. الميزة الرئيسية للتزوير هي أنه يعمل على تحسين البنية الحبيبية للفولاذ. القوة الميكانيكية محاذاة الحبوب, القضاء على الفراغات الداخلية وخلق أكثر كثافة, أقوى, وجزء أكثر مقاومة للتعب. المكونات التي تتحمل الضغط والتأثير الدوري العالي, مثل روابط المسار وقضبان التوصيل, هم المرشحين الرئيسيين للتزوير. عندما تتحدث إلى الشركة المصنعة, اسأل أي من مكوناتهم مزورة. تكشف إجابتهم عن استثمارهم في إنشاء قطع غيار بنزاهة داخلية متفوقة.

التالي صب, عملية صب المعدن المنصهر في قالب. يسمح الصب بإنشاء أشكال معقدة من الصعب أو المستحيل صياغة أو آلة. أجزاء مثل سبوكت, مع ملامح الأسنان المعقدة, غالبًا ما يتم إلقاؤها. تعتمد جودة الجزء المصبوب على نقاء المعدن المنصهر, تصميم القالب, وعملية التبريد. يمكن أن يؤدي طاقم الممثلين الذين تم إعدامهم بشكل سيئ إلى مسامية (فقاعات داخلية صغيرة) أو تشققات الانكماش, إنشاء نقاط ضعف يمكن أن تؤدي إلى الفشل تحت الحمل. ستستخدم الشركة المصنعة الكفاءة تقنيات متقدمة مثل نسبة الفراغ لإزالة الشوائب من الصلب المنصهر وملء العفن المحاكاة للكمبيوتر لضمان صلبة, صب موحد.

ولعل العملية الأكثر أهمية والتي يساء فهمها في كثير من الأحيان هي المعالجة الحرارية. هذا هو المكان الذي يتم فيه فتح الإمكانات الحقيقية لسبائك الفولاذ. It is a carefully controlled sequence of heating and cooling that alters the steel's microstructure to achieve the desired balance of hardness and toughness.

- التبريد: يتضمن ذلك تسخين الفولاذ إلى درجة حرارة عالية ثم تبريده بسرعة (في كثير من الأحيان في الماء, زيت, أو محلول بوليمر). تخلق هذه العملية بنية مجهرية صلبة للغاية ولكنها هشة تُعرف باسم مارتنسيت.

- تقع: يتم بعد ذلك إعادة تسخين الجزء المروي إلى درجة حرارة أقل ويتم الاحتفاظ به لفترة محددة. هذه العملية تخفف الضغوط الداخلية وتقلل من الهشاشة, زيادة صلابة الجزء.

دقة عملية المعالجة الحرارية هي كل شيء. الجزء الذي لم يتم تسخينه إلى درجة الحرارة الصحيحة, لا تبرد بسرعة كافية, أو لم يتم تلطيفه بشكل صحيح سوف يفشل في تلبية مواصفات أدائه. تستخدم الشركات المصنعة المتقدمة التسخين التعريفي الذي يتم التحكم فيه بواسطة الكمبيوتر لتطبيق الحرارة بدقة مذهلة على مناطق محددة - على سبيل المثال, فقط تصلب أسنان العجلة المسننة أو سطح السكة لوصلة المسار, مع ترك القلب أكثر صلابة وأكثر ليونة لامتصاص الصدمات. اسأل الشركة المصنعة عن قدرات المعالجة الحرارية الخاصة بها. هل يستخدمون تصلب التعريفي? كيف يتحكمون في معدل التبريد ودرجات الحرارة المعتدلة? وتعد قدرتهم على التحدث بالتفصيل عن هذه العمليات مؤشرًا قويًا على عمقهم الفني.

أسئلة يجب طرحها حول اعتماد المواد وإمكانية تتبعها

يثق, ولكن تحقق. This old adage is the guiding principle when evaluating a manufacturer's claims about their materials. A declaration of using "boron steel" is meaningless without a system to prove it. This is where certification and traceability become central to your inquiry. These systems provide an objective, auditable trail from the raw material supplier to the finished part on your workshop floor.

The first line of verification is the Material Test Report (MTR), sometimes called a Mill Test Certificate. This is a quality assurance document provided by the steel mill that certifies the chemical composition and physical properties of a specific batch of steel. When a manufacturer receives a shipment of raw steel, it should be accompanied by an MTR. This report is like a birth certificate for the steel, detailing its exact chemical makeup (the percentage of carbon, المنغنيز, silicon, البورون, إلخ.) and the results of mechanical tests (مثل قوة الشد والصلابة) يؤديها في الطاحونة.

يجب أن يكون سؤالك للشركة المصنعة مباشرًا: "هل تحتفظ باستعراضات منتصف المدة لجميع المواد الخام الواردة؟, وهل يمكنك ربط عملية إنتاج معينة من الأجزاء مرة أخرى بمراجعة منتصف المدة الأصلية الخاصة بها?"

وهذا يؤدي إلى مفهوم إمكانية التتبع. الشركة المصنعة مع نظام الجودة القوي, مثل شهادة ISO 9001 المعايير, سيكون لدينا إجراءات لتتبع المواد طوال عملية الإنتاج. وهذا يعني أن مجموعة محددة من دلاء الحفارات, على سبيل المثال, يمكن إرجاعها إلى الملف الدقيق أو اللوحة الفولاذية التي تم قطعها منها, وبدوره, to that steel's MTR. لا تقتصر إمكانية التتبع هذه على ضمان الجودة فحسب; إنها بوليصة التأمين الخاصة بك. إذا حدث فشل سابق لأوانه في هذا المجال, يمكن للشركة المصنعة ذات التتبع التحقيق في السبب الجذري. هل كان انحرافًا في كيمياء الصلب من تلك الدفعة المحددة? هل كان هناك مشكلة أثناء المعالجة الحرارية لهذا الإنتاج? بدون تتبع, أي تحليل فشل هو مجرد تخمين.

بالإضافة إلى, استفسر عنهم قدرات الاختبار الداخلية. بينما يوفر MTR بيانات من مصنع الصلب, ستقوم الشركة المصنعة المجتهدة حقًا بإجراء اختبارات التحقق الخاصة بها على المواد الواردة. قد يتضمن ذلك استخدام مطياف لتأكيد التركيب الكيميائي أو إجراء اختبارات الصلابة. يوضح هذا الفحص الزائد عن الحاجة التزامًا عميقًا بالجودة, نظرًا لأنها تحمي عملية الإنتاج الخاصة بهم - وعملائها - من أي هفوات جودة محتملة من مورد المواد الخام. طرح السؤال "ما هي العملية التي تتبعها للتحقق من جودة المواد الخام الواردة؟?" يمكن أن تكون كاشفة للغاية. ستوضح الإجابة الواثقة تفاصيل معدات المختبرات الداخلية وبروتوكولات الاختبار, while a hesitant one might suggest they are simply taking their supplier's word for it.

دراسة الحالة: تكلفة الفولاذ الرديء في الكسارة

لترسيخ هذه المفاهيم في الواقع الصارخ لموقع العمل, دعونا نفكر في السيناريو. شركة مقاولات صغيرة في منطقة بيلبارا بغرب أستراليا تؤمن عقد أعمال حفر الخنادق لموقع استكشاف تعدين جديد. الأرض صعبة المعروف, يتكون من اللاتريت والحجر الحديدي. إنهم يديرون أسطولًا من الحفارات الصغيرة بوزن 10 طن. لتوفير التكاليف الأولية, إنهم يحصلون على العديد من الكسارات الجديدة من أحد الموردين الذين يقدمون خصمًا كبيرًا. The supplier's documentation is sparse, ببساطة ذكر أن الكسارات مصنوعة من "عالية القوة"., فولاذ مقاوم للتآكل."

خلال الأربعين ساعة الأولى من التشغيل, الكسارات تعمل بشكل مناسب. لكن, خلال الاسبوع الثاني, اصطدم أحد المشغلين بجيب من الصخور الكثيفة بشكل خاص. بدلا من سحب الصخور مجانا, يتم تثبيت ساق الكسارة بشكل نظيف في منتصف الطريق تقريبًا للأسفل. الفشل هش, مع عدم وجود علامة على الانحناء أو التشوه. الجهاز الآن خارج الخدمة. أقرب بديل في بيرث, على بعد يومين بالسيارة.

Let's calculate the real cost of this "cheaper" جزء:

- تكلفة التوقف: الآلة, مع مشغلها, لديه معدل قابل للفوترة تقريبًا AUD $150 كل ساعة. حدث الفشل في وقت مبكر من اليوم. Let's assume 7 ساعات العمل الضائعة في اليوم الأول, بالإضافة إلى كامل 8 ساعات في اليوم الثاني أثناء انتظار الاستبدال. That's 15 ساعات من التوقف, إجمالي الدولار الأسترالي $2,250 في الإيرادات المفقودة.

- تكلفة الاستبدال: إن الكسارة عالية الجودة من شركة مصنعة حسنة السمعة كانت ستكلف دولارًا أستراليًا $1,200. The "cheaper" one was AUD $800. They now have to purchase the premium ripper anyway, plus pay for express freight from Perth, adding another AUD $300. The total replacement cost is AUD $1,500.

- Labor Costs: The operator is idle but still needs to be paid. At AUD $45/hour, that's another AUD $675 for the 15 ساعات من التوقف.

- Reputational Damage: The project is delayed by a day, straining the relationship with the primary contractor. This intangible cost can affect future contract opportunities.

The total tangible cost of the single failure of one "cheap" ripper is AUD $4,425 ($2,250 + $1,500 + $675). The initial savings of AUD $400 has resulted in a net loss of over AUD $4,000. Subsequent metallurgical analysis of the failed part would likely reveal a lower-grade steel with insufficient toughness or a flawed heat treatment process that made it excessively brittle. هذه الحالة توضح حقيقة أساسية: في الآلات الثقيلة, يعد سعر شراء أحد المكونات أحد الأجزاء الأقل أهمية من إجمالي تكلفة ملكيته. يتم الكشف عن التكلفة الحقيقية في الأداء, طول العمر, وتجنب الفشل. الأولي الخاص بك, إن الاستجواب الصارم من قبل الشركة المصنعة لأجزاء الحفارات الصغيرة حول المواد والمعادن هي الأداة الأكثر فعالية لديك لتجنب مثل هذه الدروس المكلفة.

2. هل يمكنك تفصيل عمليات التصنيع الخاصة بك وبروتوكولات مراقبة الجودة?

بمجرد التأكد من سلامة المواد الخام, يجب أن يتحول التركيز إلى تحولها. كومة من الشهادات, يكون فولاذ البورون عالي الجودة ذا قيمة قليلة إذا كانت عمليات التصنيع اللاحقة غير دقيقة أو كانت ضوابط الجودة متساهلة. يستكشف هذا الخط من الأسئلة القلب التشغيلي للشركة المصنعة لأجزاء الحفارات الصغيرة. It seeks to understand the journey of a component from a raw slab of steel to a finished, painted part ready for shipment. A manufacturer's ability to articulate their processes with clarity and detail—from the sophistication of their machinery to the rigor of their inspection checkpoints—is a direct measure of their professionalism and the reliability of their output. It separates the artisans of industry from the mere assemblers.

From Raw Steel to Finished Part: A Process Deep-Dive

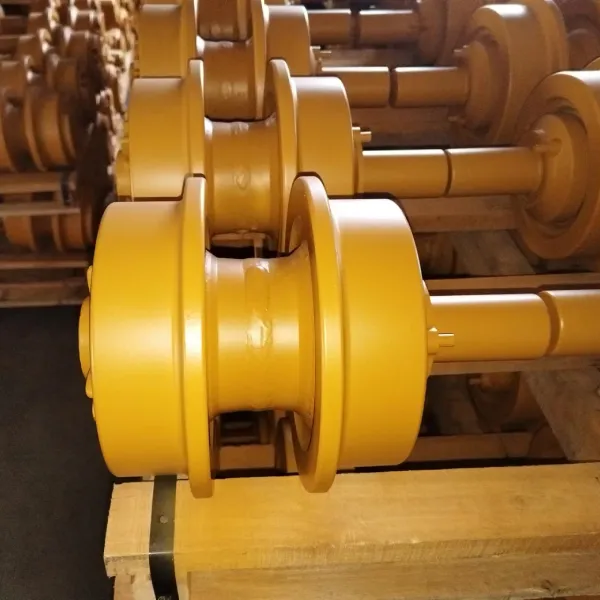

To truly appreciate the difference in manufacturing quality, it helps to visualize the life of a single component. Let's take a common but critical item: a track roller for a mini excavator's undercarriage. This part bears the entire weight of the machine, المتداول على طول سلسلة المسار تحت ضغط هائل وفي ظروف شديدة الكشط. إن إنشائها هو مسعى متعدد المراحل.

تبدأ العملية ب قطع. شريط دائري كبير من الفولاذ المحدد (ربما 40Cr أو سبيكة مماثلة) يتم قطعها إلى "الفراغات" الفردية" من الطول الصحيح. ستستخدم الشركة المصنعة الدقيقة منشارًا شريطيًا آليًا بتفاوتات دقيقة لضمان أن كل قطعة فارغة موحدة في الوزن والحجم, وهي الخطوة الأولى نحو منتج نهائي متوازن.

يأتي التالي تزوير. يتم تسخين الفراغ إلى درجة حرارة دقيقة (في كثير من الأحيان حوالي 1200 درجة مئوية) ووضعها في قالب. ومن ثم يتم الضغط بقوة على تشكيل الفولاذ الساخن إلى الشكل الخشن لأسطوانة الجنزير. كما نوقش سابقا, لا تقتصر عملية التشكيل هذه على التشكيل فقط; it's about refining the internal grain structure of the steel, imparting a strength and fatigue resistance that a cast or machined-from-bar part could never achieve.

بعد تزوير, the roller undergoes rough machining. هنا, excess material is removed, and the basic dimensions are established. This is followed by a crucial step: المعالجة الحرارية. لأسطوانة المسار, this is often a sophisticated process of induction hardening. The roller shell's running surface is heated by an electromagnetic field and then rapidly quenched. This creates an extremely hard, wear-resistant outer layer while leaving the inner core of the roller tougher and more ductile to absorb shock loads without cracking. The depth and uniformity of this hardened layer are critical for the roller's lifespan.

Following heat treatment, the part enters finish machining. This is where the final, critical dimensions are cut. Using state-of-the-art Computer Numerical Control (CNC) lathes and mills, the bearing bores and sealing surfaces are machined to tolerances measured in microns (thousandths of a millimeter). The precision here is paramount; an improperly machined sealing surface will lead to oil leaks and premature bearing failure, which is a common fate for inferior rollers.

أخيراً, حَشد. The roller shell is fitted with high-quality seals, البطانات, and a central shaft. It is filled with a specific grade of lubricating oil and sealed. A quality-conscious manufacturer will conduct a leak test on every single roller, often by pressurizing the assembled unit and submerging it in water to look for tell-tale bubbles. The last step is painting, which is not just for aesthetics but also provides a crucial layer of corrosion protection.

When you ask a manufacturer to detail this process, listen for the specifics. Do they mention CNC machining? Do they talk about induction hardening and case depth? Do they perform 100% leak testing on sealed components? The more detailed and confident their explanation, the more likely it is that they have mastered the art of manufacturing.

The Role of Quality Control Checkpoints

A robust manufacturing process is one that is interwoven with constant verification. Quality is not something that is inspected into the part at the end; it is built in at every stage. A premier mini excavator parts manufacturer operates on this principle, establishing a series of quality control (مراقبة الجودة) gates throughout the production line.

Incoming Material Inspection: As we've covered, this is the first and most vital checkpoint. It involves verifying the MTR and often performing independent spectroscopic or hardness tests on the raw steel. No material should enter the production floor without passing this gate.

In-Process Inspection: This is not a single event, but a continuous series of checks. بعد تزوير, a sample of parts might be cut open and etched to inspect the grain flow. After machining, critical dimensions are checked using calibrated instruments like calipers, micrometers, and Coordinate Measuring Machines (CMMs). A CMM is a highly advanced device that can measure a part's geometry with incredible accuracy, comparing it to the original digital blueprint.

Heat Treatment Verification: This is a checkpoint deserving of its own focus. After heat treatment, parts must be tested to ensure the process was successful. This involves checking the surface hardness (using a Rockwell or Brinell hardness tester) و, for critical components, the "case depth"—the thickness of the hardened layer. This can be done by cutting a sample part, polishing it, and measuring the hardened layer under a microscope.

اختبار غير مدمر (NDT): For high-stress components like buckets welds or ripper shanks, visual inspection is not enough. NDT methods are used to find flaws that are invisible to the naked eye. Magnetic Particle Testing (MPT), على سبيل المثال, can reveal surface and near-surface cracks in ferromagnetic materials. اختبار الموجات فوق الصوتية (يوتا) uses sound waves to detect internal flaws like porosity in castings or incomplete fusion in welds. The use of NDT is a hallmark of a manufacturer dedicated to preventing field failures.

Final Assembly & Functional Testing: Before a part is painted and packed, a final inspection confirms all components are present and correctly assembled. For assemblies like track rollers or final drives, this includes functional tests like the leak testing mentioned earlier or checking the rotational torque to ensure bearings are correctly installed.

When you interview a manufacturer, ask them to map out their QC checkpoints for a specific product, مثل أ heavy duty excavator bucket. Where do they inspect? What do they measure? What instruments do they use? What happens when a part is found to be non-conforming? Their answers will paint a clear picture of their quality culture.

Comparing Manufacturing Philosophies: OEM مقابل. ما بعد البيع

The world of machinery parts is broadly divided into Original Equipment Manufacturer (تصنيع المعدات الأصلية) parts and aftermarket parts. لكن, the "aftermarket" category is vast, ranging from suppliers who rival OEM quality to those who produce dangerously substandard components. Understanding these distinctions is key to making an informed choice. A high-quality aftermarket manufacturer provides a compelling value proposition, often delivering OEM-level quality without the associated price tag.

Here is a table to clarify the philosophical and practical differences:

| ميزة | OEM Manufacturer | High-Quality Aftermarket Manufacturer | Low-Quality Aftermarket Manufacturer |

|---|---|---|---|

| Material Specification | Follows strict, proprietary standards developed through extensive R&د. | Aims to match or exceed OEM specifications, often using industry-standard high-grade alloys. Transparent about material choices. | Often vague or misleading. May use cheaper, lower-grade steel substitutes to cut costs, leading to poor wear resistance and brittleness. |

| ر&D Investment | Very high. Designs parts concurrently with the machine itself. | Moderate to high. Focuses on reverse engineering, material analysis, and process improvement. May innovate on OEM designs. | Minimal to none. Primarily focused on simple replication by visual copying, with no understanding of the underlying engineering. |

| عملية التصنيع | Highly automated and process-controlled. Significant investment in top-tier machinery (على سبيل المثال, CNC, الروبوتات). | Employs modern manufacturing techniques, including CNC machining and controlled heat treatment. Focuses on process consistency. | Often relies on older, less precise manual machinery. May skip or poorly execute critical steps like heat treatment. |

| Quality Control | Extremely rigorous, multi-stage QC integrated throughout the production line. Extensive use of CMM, NDT, and lab analysis. | Rigorous, often certified to ISO 9001. Employs a system of QC checkpoints, in-process inspection, and final testing. | Inconsistent, often limited to a basic visual check at the end. Lacks traceability and proper measurement instrumentation. |

| Price Point | الأعلى, reflecting brand name, ر&D costs, and dealer network overhead. | Competitive, offering significant savings over OEM without compromising on core quality. Represents high value. | أدنى, achieved by cutting corners on materials, العمليات, ومراقبة الجودة. Represents high risk. |

| ضمان & Support | Comprehensive warranty backed by a global dealer network. | Often offers a warranty comparable to OEM, with a clear claims process. Support is typically direct from the manufacturer. | Warranty is often limited, non-existent, or has prohibitive fine print. Support is minimal. |

Your goal as a buyer is to find a supplier firmly in that middle column: a high-quality aftermarket mini excavator parts manufacturer who has invested in the materials, العمليات, and quality systems to deliver reliable performance and genuine value.

شهادات فك التشفير: ما ايزو 9001 حقا يعني

In your search, you will frequently encounter the "ISO 9001" شهادة. It is often presented as a badge of quality, but it is vital to understand what it represents. ISO 9001 ليست شهادة المنتج; it is a certification of a company's نظام إدارة الجودة (نظام إدارة الجودة).

Think of it this way: ISO 9001 does not guarantee that every single part a company produces is perfect. بدلاً من, it certifies that the company has a well-documented, consistent, and auditable system for managing quality. This system includes procedures for:

- Controlling documents and records.

- Managing resources, including personnel and equipment.

- The entire product realization process, from design to delivery.

- Measurement, تحليل, and improvement, including handling non-conforming products, conducting internal audits, and implementing corrective actions.

لذا, why is an ISO 9001 certification a positive sign? Because it indicates that the manufacturer is serious about process control. It demonstrates that they have defined their procedures, trained their people, and have a mechanism for identifying and fixing problems. A company that has gone through the rigorous process of achieving and maintaining ISO 9001 certification is far less likely to have chaotic, inconsistent production processes than one that has not (Abisourour et al., 2021). It is a strong indicator of professionalism and a commitment to repeatable outcomes.

لكن, it is only one piece of the puzzle. It tells you they have a system. Your detailed questions about their specific manufacturing and QC processes tell you how well they execute that system. The combination of a certified QMS and the ability to confidently answer your deep technical questions is the powerful one-two punch you are looking for in a top-tier mini excavator parts manufacturer.

3. ما هو نطاق بحثك, تطوير, والقدرات الهندسية?

The ability to accurately replicate a part is the baseline expectation for any aftermarket manufacturer. لكن, the truly exceptional suppliers, the ones who become long-term strategic partners, do not stop at replication. They possess a deep-seated engineering curiosity and a robust capacity for research and development (ر&د). This capability transforms them from mere copyists into innovators who understand the why behind a part's design, not just the what. Inquiring into a manufacturer's R&D efforts is to probe their intellectual core. It reveals whether they are passively following the market or actively working to advance it, solving real-world problems for customers operating in challenging conditions from the frozen ground of Siberia to the abrasive sands of the Middle East.

Beyond Replication: The Value of In-House Engineering

A low-quality manufacturer might take an OEM part, measure it with calipers, and create a copy. A high-quality manufacturer with an in-house engineering team approaches the task from a completely different perspective. Their goal is not just to replicate the form, but to understand the function and, where possible, to improve upon it. This process is often called reverse engineering.

It begins with data acquisition. Instead of simple hand measurements, an engineering-driven company will use a 3D laser scanner or a Coordinate Measuring Machine (CMM) to create a highly precise digital model of the original part. This digital blueprint is far more accurate and detailed than any 2D drawing.

But the real engineering work happens next. The digital model is imported into Computer-Aided Engineering (CAE) برمجة. هنا, engineers can perform Finite Element Analysis (FEA). This is a powerful computational tool that allows them to simulate how the part will behave under real-world stresses. They can apply virtual loads, pressures, and vibrations to the digital model to see where stress concentrates. Think of it as a virtual stress test that can reveal the hidden weak points in a design.

Why is this important? An OEM might design a part to be "good enough" for a wide range of average conditions. لكن, an FEA analysis might reveal that under the specific high-stress conditions of, على سبيل المثال, constant rock breaking with a chisel, a certain area of the tool holder is prone to fatigue cracking. An engineering-led aftermarket manufacturer can use this insight to improve the design. They might add a reinforcing gusset, increase the radius of a sharp internal corner to distribute stress more evenly, or select a tougher steel alloy for that specific component. They are not just copying the part; they are solving a problem.

When you speak with a potential supplier, ask if they have an in-house engineering department. Do they use software for 3D modeling and FEA? Can they provide an example of how their engineering analysis led to a product improvement? A manufacturer who can share such a story is demonstrating a level of sophistication that goes far beyond simple imitation. They are showing that they think like problem-solvers.

Innovation in Wear Parts: Adapting to Modern Demands

The world of construction and excavation is not static. New techniques, more powerful machines, and increasingly demanding applications require that wear parts evolve as well. A manufacturer stuck in a purely replicative mindset will always be one step behind, producing parts for yesterday's challenges. A forward-thinking mini excavator parts manufacturer with a strong R&D focus is constantly looking ahead.

Consider the evolution of the excavator bucket. A standard-duty digging bucket is a versatile tool, but it is not optimal for every task. An innovative manufacturer will offer a diverse range of specialized buckets, each designed and engineered for a specific purpose:

- Heavy-Duty Rock Buckets: These are not just standard buckets made with thicker plate. They are engineered with a different profile (often a V-shape) for better penetration in rock. They feature extensive use of high-abrasion steel (مثل AR450 أو AR500) on all wear surfaces, reinforced side-cutters, and robust lip shrouds to protect the leading edge.

- Skeleton Buckets: Used for sorting rock from soil on a demolition site or in a quarry. The R&D here focuses on the spacing of the ribs. Too wide, and you lose valuable material; too narrow, and the bucket clogs constantly. Engineering analysis and field testing are required to find the optimal geometry for different material types.

- Trenching Buckets: These narrow buckets require careful design to ensure they have the strength to dig in tough conditions without the width to provide it. The engineering challenge is in the structural design of the bucket's "ears" and hanger, where all the force is concentrated.

- Tilt Buckets: These complex hydraulic attachments require a blend of mechanical and hydraulic engineering expertise to ensure they are both powerful and reliable.

Innovation also occurs at the micro level, in the أدوات المشاركة الأرضية (يحصل)—the teeth, محولات, and cutting edges. ر&D in this area is heavily focused on metallurgy. Manufacturers are constantly experimenting with new steel alloys and heat treatment profiles to create teeth that offer a better balance of hardness (for wear) والمتانة (لمقاومة التأثير). They might develop new locking systems that make changing teeth faster and safer for operators in the field.

Ask a potential supplier: "What new products or product improvements have you introduced in the last two years?" Their answer will tell you if they are an active participant in the industry's evolution or a passive observer. Look for a supplier whose catalog of available parts shows a thoughtful diversity beyond just standard replacement items.

The Feedback Loop: How Customer Experience Drives Product Improvement

The most valuable R&D resource for any manufacturer is not in a lab; it's on the job sites of their customers. The daily experiences of operators in Korea, أستراليا, روسيا, and Africa are a treasure trove of data on how parts perform and fail in the real world. A truly excellent manufacturer has a formal system for capturing, analyzing, and acting on this feedback.

This is the concept of the customer feedback loop. It works like this:

- Data Collection: The manufacturer actively seeks feedback. This can be through their sales team, technical support lines, warranty claims process, or by conducting regular visits to customer sites. They don't wait for complaints; they proactively ask, "How is the part performing? What challenges are you facing?"

- تحليل: The feedback, especially regarding failures or premature wear, is not just handled by a customer service agent. It is routed directly to the engineering department. A failed part might be requested back for a full failure analysis, including metallurgical testing and microscopic examination, to determine the root cause.

- Action: The insights gained from this analysis are then used to drive real change. If a specific model of track shoe is showing accelerated wear in the abrasive soils of a particular region, the engineers might decide to change the steel specification or modify the heat treatment profile for that part. If customers report difficulty installing a certain seal, the engineers might redesign the part or create a more detailed installation guide.

- Communication: The loop is closed when the manufacturer communicates back to the customer base. This could be through a technical bulletin explaining the improvement or simply by the improved product becoming the new standard.

This process transforms the customer-supplier relationship from a simple transaction into a partnership. The manufacturer is not just selling steel; they are selling a continuously improving solution. When vetting a supplier, ask them to describe their process for handling a field failure report. Who gets involved? What analysis is done? Can they give an example of a product improvement that was a direct result of customer feedback? A manufacturer who embraces this feedback loop is one who is committed to the long-term success of their clients. They understand that their own success is intrinsically linked to the performance and durability of their products in the diverse and demanding environments where they are put to the test.

4. كيف يمكنك ضمان توافق جزء وتركيب عبر علامات تجارية ونماذج مختلفة?

In an ideal world, every part would snap into place perfectly, every time. In the complex reality of heavy machinery, achieving this "perfect fit" is a significant engineering and logistical challenge. The mini excavator market is particularly fragmented, with dozens of manufacturers (like Kubota, Yanmar, Bobcat, يرقة, كوماتسو, هيتاشي, و Doosan) each producing numerous models with unique specifications that can change from one production year to the next. For an aftermarket mini excavator parts manufacturer, guaranteeing fitment is not a trivial matter; it is a core competency that separates reliable suppliers from sources of frustration and downtime. This question probes the precision of their data, the rigor of their processes, and the strength of their guarantee.

The Challenge of a Fragmented Market

To grasp the scale of the challenge, consider the undercarriage of a single 5-ton mini excavator. It is a complex system of interlocking components: dozens of track links forming the chain, multiple track rollers and top rollers, a front idler, and a rear sprocket. الآن, imagine that the specifications for the pitch of the track chain (the distance from one pin to the next), the diameter of the rollers, the bore of the idler, and the tooth profile of the sprocket can all vary slightly between a machine made by Brand A and one made by Brand B, even if they are in the same weight class. Worse, Brand A might change the design of its sprocket between its 2023 model and its 2025 نموذج.

A manufacturer attempting to serve the global market must contend with this enormous matrix of variations. A track chain that fits a Kubota KX057-4 will not fit a Yanmar ViO55-6A. A bucket linkage pin for a Bobcat E50 may be a millimeter different in diameter from one for a Cat 305. These small deviations are the difference between a smooth installation and a costly problem. An ill-fitting part can lead to:

- Installation Failure: The part simply won't go on, leading to immediate downtime while the correct part is sourced. This is especially painful for customers in remote locations, like mining sites in Africa or agricultural operations in Southeast Asia, where shipping can take weeks.

- Accelerated Wear: A sprocket with a slightly incorrect tooth profile might engage with the track chain bushings improperly. While it may seem to work initially, this mismatch will cause rapid, destructive wear to both the new sprocket and the existing track chain, turning a single component replacement into a full undercarriage rebuild.

- Catastrophic Failure: An improperly fitting pin or bolt can create unforeseen stress concentrations, leading to a sudden fracture of a component under load, which poses a serious safety risk.

This is why a casual approach to compatibility is unacceptable. A manufacturer cannot simply rely on old catalogs or visual comparisons. They must treat fitment as a discipline of precision.

Leveraging OEM Data and Precision Measurement

لذا, how does a top-tier manufacturer conquer this challenge? They build a "library of fitment," a vast and meticulously maintained database of OEM specifications. This is not something that can be bought off the shelf; it is a strategic asset built over years of painstaking work.

The foundation of this library is data acquisition. The process for a new part might look like this:

- Procure the OEM Part: The manufacturer obtains a genuine OEM component for the specific machine model they wish to support.

- 3D Digital Scanning: The part is scanned using a high-resolution 3D laser scanner. This non-contact method captures the complete external geometry of the part, creating a "point cloud" of millions of data points.

- CMM Measurement: For critical interface points—such as bearing bores, pin holes, mounting surfaces, and gear teeth—a Coordinate Measuring Machine (CMM) يستخدم. The CMM's tactile probe can measure these features with sub-micron accuracy, capturing the precise dimensions and geometric tolerances (like concentricity and perpendicularity) that a laser scanner might miss.

- Create the "Golden" CAD Model: The scan data and CMM measurements are combined to create a highly accurate 3D Computer-Aided Design (CAD) نموذج. This is the manufacturer's "golden" reference, the digital master against which all production parts will be compared.

This data-driven approach is fundamentally different from simple copying. It captures the design intent of the original engineers. The manufacturer's engineering team will maintain this database, constantly updating it as new machine models are released. When you order a ripper for your specific mini excavator, they are not just pulling a generic part off the shelf. They are matching your machine's make, نموذج, and serial number against their database to ensure the mounting bracket, pin dimensions, and hydraulic connections are an exact match.

Ask a potential supplier: "How do you obtain the dimensional data for the parts you manufacture? What technology do you use to measure and verify these dimensions?" Look for answers that include terms like "3D scanning," "CMM," and "CAD model database."

The "Fitment Guarantee": What to Look for in a Warranty

A manufacturer who is confident in their data and their production tolerances will stand behind their product with a clear and unambiguous fitment guarantee. This guarantee is one of the most powerful indicators of a supplier's quality and customer focus. لكن, not all guarantees are created equal. Here is what to look for in the fine print:

- Clarity: The policy should be simple. It should state that if the part does not fit the specified machine for which it was sold, the manufacturer will rectify the situation.

- Scope of Remedy: What does the manufacturer promise to do? A good guarantee will offer a full refund or, والأهم من ذلك, an expedited shipment of the correct part at their expense. The best policies may even offer some form of compensation for the downtime caused by their error, though this is less common.

- Cost Coverage: Who pays for shipping? A strong guarantee will state that the manufacturer covers the cost of shipping the incorrect part back and the cost of shipping the new part out. This is a major consideration for international customers, where shipping costs can be substantial.

- Simplicity of Process: How do you make a claim? It should be a simple process involving contacting their technical support, providing the machine details and photos of the fitment issue. A convoluted, multi-step process with excessive paperwork is a red flag.

The existence of a strong fitment guarantee tells you two things. أولاً, it shows that the manufacturer has invested heavily in their data and quality control, because they are financially confident that fitment issues will be rare. ثانية, it shows that they respect their customers' time and business, and are prepared to take responsibility when an error does occur. It shifts the risk of an incorrect part from you, the buyer, back to them, the manufacturer.

A Second Comparison Table: Fitment Risk Factors

To summarize the key differentiators, consider this table when evaluating a potential supplier's approach to compatibility:

| عامل | Low-Risk Manufacturer | High-Risk Manufacturer |

|---|---|---|

| Data Source | Meticulously maintained database built from OEM part scanning (3د) and CMM measurement. | Relies on outdated catalogs, visual copying from photos, or simple hand measurements. |

| هندسة | In-house engineering team that creates and verifies detailed CAD models for every part. | No dedicated engineering for fitment. Production is based on simple drawings or physical copies. |

| Production Tolerances | Tightly controlled using CNC machining and regular calibration of equipment. | Loose tolerances due to manual processes or poorly maintained machinery, leading to part-to-part variation. |

| Verification | Production parts are regularly checked against the "golden" CAD model using CMMs or precision fixtures. | Inspection is limited to basic go/no-go gauges or visual checks, if it happens at all. |

| Fitment Guarantee | Clear, شامل, and customer-friendly. Covers return and replacement shipping costs. | Vague, full of exclusions, or non-existent. The buyer bears the risk and cost of an incorrect part. |

| Technical Support | Staffed by knowledgeable technicians who can troubleshoot fitment issues based on serial numbers and machine specs. | Handled by sales staff who lack deep technical knowledge and cannot provide effective support. |

أخيرًا, a manufacturer's approach to fitment is a proxy for their overall attention to detail. A company that is meticulous about ensuring a part fits is also likely to be meticulous about the quality of their steel, the precision of their heat treatment, and the integrity of their welds.

5. ما هي استراتيجية لوجستية وسلسلة التوريد العالمية الخاصة بك, خاصة بالنسبة لمنطقي?

A perfectly manufactured component is of no use if it cannot be delivered to your job site in a timely, موثوق, and cost-effective manner. For businesses operating in geographically diverse and often challenging markets—from the vast expanses of the Australian Outback to the bustling ports of Southeast Asia or the remote industrial zones of Russia—logistics is not an afterthought. It is a core element of the value proposition. When you question a mini excavator parts manufacturer about their supply chain, you are assessing their ability to operate on a global scale. You are gauging their understanding of your regional realities and their preparedness to be a dependable partner, not just a distant factory.

From Factory Floor to Job Site: Navigating Global Shipping

The journey of a heavy steel part, like an excavator bucket or a set of undercarriage tracks, from a factory in Asia to a customer in the Middle East is a complex ballet of transportation, documentation, and regulation. A sophisticated manufacturer understands and manages this complexity on behalf of their customers.

The primary mode of transport for such heavy goods is ocean freight. It is the most economical method, but it requires careful planning. A manufacturer must have strong relationships with freight forwarders and shipping lines to secure space on vessels and negotiate competitive rates. They should be able to provide you with clear estimates for transit times to your nearest port.

For more urgent needs, air freight is an option, but it comes at a significantly higher cost. A good supplier can provide quotes for both, allowing you to make an informed decision based on the urgency of your need versus the cost.

Beyond the transport itself lies the labyrinth of customs and documentation. Every country has its own set of rules for imports, including required documents (like the Bill of Lading, Commercial Invoice, and Packing List), import duties, and taxes (like VAT or GST). A seasoned global supplier will have an export department that is expert in preparing this documentation accurately. Errors in paperwork can lead to lengthy and costly delays at customs. They should also be able to provide the correct HS (Harmonized System) codes for their products, which are essential for customs classification and duty calculation. Ask them: "What support do you provide for customs clearance in my country?" Their answer will reveal their level of international experience.

The Importance of Regional Distribution Hubs

For a customer in Dubai or Singapore, a manufacturer's promise of "fast shipping" is meaningless if the parts must first travel for four weeks on a ship from a single factory in Northeast Asia. Lead time—the total time from placing an order to receiving the goods—is a critical factor in managing your inventory and responding to unexpected machine failures.

This is why the most forward-thinking manufacturers adopt a hub-and-spoke model for their distribution. Instead of shipping every individual order directly from the factory (the spoke-to-customer model), they establish regional distribution centers or warehouses in strategic locations (the hubs). على سبيل المثال:

- A hub in Dubai (Jebel Ali Free Zone) could efficiently serve the entire Middle East and parts of Africa.

- A hub in Singapore or Malaysia (Port Klang) could drastically reduce lead times for the booming construction markets across Southeast Asia (Indonesia, Thailand, Vietnam).

- A European hub, perhaps in Rotterdam or Antwerp, could serve Russia, the CIS countries, and North Africa.

- A presence in أستراليا (على سبيل المثال, Perth or Brisbane) would be a massive advantage for serving the continent's sprawling mining and construction sectors.

By stocking high-volume parts in these regional hubs, a manufacturer can cut lead times from weeks to days. An order from a customer in Qatar could be fulfilled from the Dubai hub in 2-3 أيام, rather than 3-4 weeks from the factory. This has a profound impact on your business. It allows you to operate with a leaner inventory, freeing up cash flow. It means a downed machine can be back up and running in days, not weeks, saving thousands in lost revenue.

When vetting a supplier, this is a powerful question: "Do you have any warehousing or distribution partners located in or near my region?" A "yes" to this question can be a significant competitive advantage and a strong reason to partner with that manufacturer.

Packaging and Preservation: Protecting the Investment

A track roller that arrives rusted or a bucket that is dented from shifting in a container is a failed delivery, regardless of how well it was manufactured. The final stage of the production process—packaging—is a critical quality step, especially for goods undertaking a long and arduous journey across the ocean.

Heavy steel parts present unique packaging challenges. They are dense, often have sharp edges, and are susceptible to both physical damage and corrosion. A quality-focused mini excavator parts manufacturer will have a detailed packaging protocol:

- Corrosion Protection: Steel parts traveling by sea are exposed to a humid, salty environment for weeks. Simply painting them is not always enough. Quality suppliers will apply a layer of anti-rust oil or wax. For finished, unpainted surfaces like bearing bores, they might use VCI (Vapor Corrosion Inhibitor) paper or bags, which emit a harmless vapor that creates a protective molecular layer on the metal surface.

- Physical Protection: Individual parts should be protected from banging against each other. Small components might be individually boxed. Larger items like rollers and idlers should have protectors on machined surfaces.

- Crating and Palletizing: The parts are then securely packed into custom-built wooden crates or strapped onto heavy-duty pallets. The goal is to create a solid, stable block that will not shift or break apart during handling or in rough seas. The wood used for these crates must often be fumigated and certified to ISPM 15 standards to comply with international quarantine regulations—another detail an experienced exporter will handle automatically.

Look at a manufacturer's product photos. Do they show parts neatly arranged in sturdy, well-built crates? Or are they just piled loosely on a pallet? Ask for photos of how their products are packaged for export. It is a small detail that speaks volumes about their professionalism and respect for the product you are purchasing.

Understanding Incoterms: Who is Responsible for What?

When you receive a price quote from an international supplier, it will be accompanied by a three-letter code like "FOB," "CIF," or "EXW." These are Incoterms, a set of globally recognized rules that define the responsibilities of the seller and the buyer in an international transaction. Understanding them is vital to knowing your total landed cost and your risks.

- EXW (Ex Works): This term places the maximum responsibility on you, the buyer. The price quoted is simply the price of the goods at the factory gate. You are responsible for arranging and paying for everything else: transport from the factory, export customs, ocean freight, insurance, import customs, and final delivery. This option gives you control but also requires significant logistical expertise.

- FOB (Free On Board): This is one of the most common terms. The manufacturer is responsible for all costs and processes to get the goods loaded onto the vessel at the designated port of origin. From that point forward, you are responsible for the ocean freight, insurance, and all subsequent costs and risks.

- CIF (يكلف, Insurance, and Freight): With CIF, the manufacturer takes on more responsibility. They arrange and pay for the cost of the goods, the ocean freight to your destination port, and the insurance to cover the goods during transit. Your responsibility begins when the goods arrive at your country's port. You must handle customs clearance, import duties, and transport from the port to your location.

A good manufacturer will be flexible and able to quote you prices based on different Incoterms. They should also be able to clearly explain what each term means for you. This educational approach demonstrates that they are not just trying to make a sale, but are trying to build a transparent and understandable business relationship. It allows you to accurately calculate your total landed cost and avoid any surprise expenses, which is the foundation of a healthy and sustainable supply partnership.

6. هل يمكنك تقديم دليل على الأداء والمتانة من خلال دراسات الحالة والشهادات?

Claims are easy to make. "Durable," "long-lasting," and "high-performance" are words that flow freely in marketing brochures. But for the discerning buyer of heavy equipment parts, these words are hollow without proof. The sixth crucial question you must ask a potential mini excavator parts manufacturer is for tangible evidence that their products perform as advertised in the unforgiving laboratory of the real world. This inquiry moves the conversation from the theoretical realm of specifications and processes to the practical domain of results. It demands that the manufacturer substantiate their claims with data, stories, and references that are relevant to your specific operational context.

Moving Beyond Marketing Claims: The Need for Proof

In any industry, there is a gap between what is promised and what is delivered. In the world of construction machinery, that gap can be measured in thousands of dollars of unplanned expenses and lost productivity. Your task as a buyer is to bridge that gap with information before you commit your capital. You must cultivate a healthy skepticism toward unsubstantiated marketing language and instead adopt an evidence-based approach.

Think of yourself as an investigator. The manufacturer is making a case that their product—be it a bucket, a ripper, or a set of undercarriage components—is a wise investment. Your job is to cross-examine their evidence. This evidence can take several forms, but it must always be specific and verifiable. A vague statement like "our parts last longer" is not evidence. A documented report showing that their track links achieved 4,500 hours of operation in abrasive silica sand before needing replacement, while a competitor's product lasted only 3,000 hours under the same conditions, is evidence. It is your right and your responsibility to ask for this level of proof.

Analyzing a Meaningful Case Study

A well-constructed case study is one of the most powerful forms of evidence a manufacturer can provide. It is a narrative of performance, a story with a beginning (the problem), a middle (the solution), and an end (the result). لكن, not all case studies are created equal. Here is how to dissect a case study to determine its value:

Context is Key: A meaningful case study will begin by setting the scene in detail.

- Machine: What was the exact make and model of the mini excavator? (على سبيل المثال, a Caterpillar 308 CR)

- طلب: What was the machine doing? (على سبيل المثال, حفر الخنادق, هدم, bulk earthmoving, rock breaking).

- Operating Conditions: This is the most important element. Was the environment highly abrasive (على سبيل المثال, sand and gravel quarry in the UAE)? Was it high-impact (على سبيل المثال, demolition of reinforced concrete in Seoul)? Was it low-impact but highly corrosive (على سبيل المثال, working in swampland in Indonesia)? The conditions dictate the wear patterns and failure modes.

- موقع: Knowing the geographic location helps you assess its relevance to your own operations.

The Comparison: A case study is most powerful when it includes a direct comparison. This could be a "before and after" سيناريو, comparing the performance of the manufacturer's part against the part it replaced (which could be an OEM part or a competitor's aftermarket part). The metric for comparison must be clear. For wear parts, the universal metric is cost per hour.

- Cost Per Hour = (Purchase Price of Part) / (Total Service Hours Achieved)

The Data: The results should be presented with quantifiable data, not just qualitative descriptions.

- Service Life: How many hours did the part last? This should be measured using the machine's hour meter.

- Maintenance Interventions: Were there any unexpected maintenance needs during the part's life?

- Measurements: For wear parts, a great case study might include wear measurements taken at set intervals, showing the rate of material loss over time.

Let's imagine a case study for a set of bucket teeth. A weak case study would say: "A customer in Australia used our teeth and was very happy with the long life." A strong case study would state: "A gold mining operation near Kalgoorlie, Western Australia, fitted our X-400 series teeth to their 8-ton excavator used for clearing abrasive, quartz-rich overburden. The previous OEM teeth had an average service life of 350 hours at a cost of $80 per tooth, resulting in a cost per hour of $0.23. Our X-400 teeth, under identical conditions, achieved an average service life of 500 ساعات. At a purchase price of $90 per tooth, our cost per hour was $0.18. This represents a 22% reduction in operating costs for bucket teeth." This level of detail is credible, compelling, and allows you to perform your own analysis.

The Value of Regional-Specific Testimonials

While case studies provide hard data, testimonials offer a human perspective. They speak to the qualitative aspects of a supplier relationship: سهولة التثبيت, customer service, and overall satisfaction. لكن, just like with case studies, the relevance of a testimonial is highly dependent on its context.

For a construction company in Johannesburg, جنوب أفريقيا, a glowing review from a contractor in Norway is of limited value. Their operating environments—climate, soil conditions, labor practices, and supply chain realities—are completely different. What that South African company needs is to hear from another business operating in the high-altitude, rocky conditions of the Highveld.

A globally astute mini excavator parts manufacturer understands this. They will not just have a generic "Testimonials" page on their website. They will be able to provide you with references or testimonials from customers in your specific region.

- If you are in روسيا, you want to hear from someone who has used their undercarriage parts through a Siberian winter.

- If you are in the الشرق الأوسط, you want a testimonial from a company that can attest to how the seals and hydraulic components stand up to extreme heat and fine, abrasive dust.

- If you are in جنوب شرق آسيا, you want to know how their paint and coatings resist the corrosion of a hot, humid, and salt-laden atmosphere.

When you ask for testimonials, be specific: "Can you provide me with a reference or a testimonial from a customer in my country, or in a country with a similar operating environment?" A manufacturer with a deep and diverse global customer base will be able to fulfill this request. Their ability to do so is strong proof that their products are not just designed in a lab but are proven to work across the varied and demanding job sites of the world.

How to Spot a Fake or Low-Value Testimonial

In the digital age, it is easy to fabricate positive reviews. As a savvy buyer, you should learn to recognize the signs of inauthentic or low-value feedback.

- Overly Generic Language: Phrases like "Great product, fast shipping!" or "Five stars, highly recommend!" without any specific detail are often signs of low-effort or fake reviews.

- Lack of Verifiable Detail: Authentic testimonials usually include specifics. The person might mention their machine type, the job they were doing, or a particular feature of the part they appreciated. They often name their company and location. A testimonial from "John S." is far less credible than one from "John Smith, Site Manager, ABC Construction, Perth, WA."

- "Stock Photo" Vibe: Be wary of testimonials accompanied by generic stock photos of excavators rather than real pictures from the customer's job site.

- Exclusively Positive: A collection of nothing but flawless, five-star reviews can be suspicious. Real product experiences are nuanced. A credible manufacturer might even share a story about how they resolved a customer's problem, which can be more powerful than a simple glowing review.

Your quest for evidence is a critical due diligence step. It protects you from inflated marketing promises and grounds your decision in the bedrock of real-world performance. A manufacturer who willingly and transparently provides detailed case studies and relevant testimonials is a manufacturer who is confident in their product and respects your need for verifiable proof.

7. ما هو مستوى دعم ما بعد البيع والخبرة التقنية التي تقدمها?

The relationship with a mini excavator parts manufacturer should not end when your payment is processed or when the shipment arrives at your port. The delivery of the component marks the beginning of a new, long-term phase of the partnership. The quality of this post-purchase relationship is defined by the manufacturer's after-sales support and technical assistance. This final question probes the supplier's commitment to your success long after the initial transaction. It explores their warranty policies, the accessibility and knowledge of their technical team, and the resources they provide to ensure their products are used correctly and deliver maximum value. A superior manufacturer views the sale as the start of a collaboration, not the conclusion of a deal.

The Partnership Begins After the Sale

Imagine this scenario: a new, aftermarket final drive arrives for a mini excavator that is down on a critical job. Your mechanic begins the installation but finds that the hydraulic hose fittings are slightly different from the old unit. The installation manual is a poorly translated, single-page document. The machine is losing money every hour it sits idle. You call the supplier. الآن, you face a critical juncture that reveals the true character of the manufacturer.

- Scenario A (Poor Support): You are routed to a generic call center. The agent does not understand what a final drive is and can only read from a script. They promise someone will call you back. Hours or days pass.

- Scenario B (Excellent Support): You are connected directly to a technical support department. The person on the line is an experienced technician or engineer. You explain the issue, providing the machine's model and serial number. يدركون على الفور المشكلة, شرح ذلك لنطاق الأرقام التسلسلية المحددة هذا, مطلوب محول مناسب, التي أدرجوها في الشحنة. أنها توجه ميكانيكي الخاص بك إلى الصغيرة, جزء منفصل, وفي غضون دقائق, عاد التثبيت إلى المسار الصحيح.

هذا هو الفرق بين المورد البسيط والشريك الحقيقي. يدرك الشريك أن مسؤوليته تمتد إلى ضمان تثبيت الجزء بشكل صحيح ويؤدي كما هو متوقع. لقد استثمروا في البنية التحتية للدعم لحل المشكلات بسرعة وكفاءة لأنهم يفهمون أن وقت التشغيل الخاص بك هو مقياس النجاح النهائي الخاص بك.

تقييم المعرفة التقنية لفريق الدعم

تتوقف فعالية نظام دعم ما بعد البيع بالكامل على معرفة وتمكين شعبها. When vetting a potential mini excavator parts manufacturer, you need to assess the depth of their technical bench.

A key differentiator is the separation of sales and technical support. While a salesperson is expert in pricing and logistics, they are rarely equipped to diagnose a complex mechanical or hydraulic issue. A premier manufacturer maintains a dedicated technical support team composed of individuals with hands-on experience: former mechanics, field service technicians, or engineers.

When you have a technical question—either before or after a purchase—you should have a direct line to these experts. Their role is not to sell you something, but to solve your problem. They should be able to:

- Answer detailed installation questions.

- Help troubleshoot a performance issue (على سبيل المثال, "Why is my new bucket not curling with full force?").

- Assist in failure analysis, understanding wear patterns to offer advice on extending component life.

- Provide technical specifications that may not be in the general catalog, such as bearing preload values or hydraulic pressure settings.

A simple way to test this is to call the manufacturer with a hypothetical technical question before you ever place an order. على سبيل المثال: "I am considering your chisel for my Doosan DX63-3. What is the recommended operating pressure, and what are the signs that the accumulator needs recharging?" The quality of the answer you receive—its accuracy, clarity, and the confidence with which it is delivered—will tell you everything you need to know about their commitment to technical excellence.

Warranty Policies: The Fine Print Matters

A warranty is a manufacturer's written promise about the quality of their product. It is a form of insurance for you, the buyer. لكن, the value of that insurance is determined entirely by the terms and conditions—the "fine print." A "12-Month Warranty" banner can hide a multitude of exclusions that render it nearly useless.

When evaluating a warranty policy, look for the answers to these questions:

- What is the Warranty Period? Is it measured in months, سنين, or service hours? For wear parts, a warranty based on hours is often more relevant than one based on time.

- What is Covered? Does the warranty cover only "defects in materials and workmanship"? This is a standard and reasonable limitation. Be wary of warranties that have long lists of specific exclusions.

- What is Not Covered? Pay close attention to the exclusions. Common and fair exclusions include improper installation, lack of routine maintenance, application overload (using the part beyond its design limits), and normal wear. Unfair exclusions might be overly broad, such as "void if used in abrasive conditions," which would disqualify most real-world use for a digger.

- What is the Remedy? If a part fails under warranty, what will the manufacturer do? Will they repair the part, replace it, or offer a credit? A good warranty provides a replacement part.

- Are Consequential Costs Covered? This is a major differentiator. A standard warranty will only cover the cost of the part itself. It will explicitly exclude the cost of labor to remove the old part and install the new one, the cost of machine downtime, and any damage the failed part may have caused to other components. While full consequential damage coverage is rare outside of OEM warranties, some top-tier aftermarket manufacturers may offer a contribution toward labor costs as a sign of goodwill.

- What is the Claim Process? Is it straightforward? عادة, it should involve contacting the technical support team, providing proof of purchase, the machine's service hours, and evidence of the failure (photos, videos, or sometimes returning the part for inspection). A process that requires excessive bureaucracy is a red flag.

A transparent, عدل, and easily understood warranty policy is a sign of a manufacturer that stands behind its product with integrity.

Proactive Support: Installation Guides, Videos, and Training

The best manufacturers do not just wait for you to have a problem. They proactively provide resources to prevent problems from occurring in the first place. This demonstrates a deep-seated culture of customer success. This proactive support can take many forms:

- Detailed Installation Manuals: Not just a single sheet, but a comprehensive, well-written guide with clear diagrams or photos for every major step. For complex components, this might include torque specifications for bolts and tips for seating seals correctly.

- Video Tutorials: In today's visual world, a short video showing the correct procedure for changing an undercarriage roller or replacing bucket teeth can be far more effective than a written manual. A manufacturer who invests in creating a library of these videos is investing in their customers' success.

- Technical Bulletins: When an improvement is made or a common issue is identified, a proactive manufacturer will issue a technical bulletin to its dealer network and customers, providing valuable information.

- Maintenance Recommendations: Beyond just selling the part, they provide guidance on how to maintain it to achieve the longest possible service life. This could include information on proper track tensioning to extend undercarriage life or tips on welding techniques for repairing a bucket.

This library of resources is a powerful indicator of a manufacturer's maturity and expertise. It shows that they have accumulated a wealth of knowledge and are committed to sharing it for the benefit of their customers. When you choose a supplier, you are not just buying their parts; أنت أيضًا يمكنك الوصول إلى نظام المعرفة والدعم. يعد اختيار الشركة المصنعة ذات نظام بيئي غني من الدعم الاستباقي خطوة استراتيجية تدفع أرباحًا في تكاليف الصيانة المخفضة, زيادة وقت التشغيل, وفريق أكثر دراية.

الأسئلة المتداولة (التعليمات)

س 1: ما هو الفرق الرئيسي بين OEM وأجزاء الحفارة المصغرة عالية الجودة? الاختلافات الأساسية تكمن في السعر و, أحيانا, ابتكار. تصنيع المعدات الأصلية (الشركة المصنعة للمعدات الأصلية) parts are made by or for the machine's brand and guarantee perfect fitment, لكن تعال بأعلى سعر. يتم إنتاج أجزاء ما بعد البيع عالية الجودة من قبل الشركات المصنعة لجهات خارجية تهدف إلى تلبية أو تجاوز مواصفات OEM في المواد, ملائم, والأداء, ولكن في نقطة سعر أكثر تنافسية. في بعض الحالات, هؤلاء المصنعون يبتكرون في التصميم الأصلي, تقديم تحسينات بناءً على البيانات الميدانية من مجموعة واسعة من التطبيقات.

Q2: كيف يمكنني التأكد من أن جزء ما بعد البيع سوف يناسب طراز الحفريات المصغرة الخاص بي? تضمن الشركة المصنعة لما بعد البيع ذات السمعة الطيبة التناسب من خلال عملية صارمة للهندسة العكسية. يستخدمون الماسحات الضوئية و CMMs ثلاثية الأبعاد (تنسيق آلات القياس) لإنشاء نماذج رقمية دقيقة لأجزاء OEM الأصلية. يحتفظون بقاعدة بيانات واسعة تصنع أرقام الأجزاء المرجعية مع الجهاز, نماذج, ونطاقات الأرقام التسلسلية. Always provide your machine's full details when ordering and ask about their fitment guarantee, التي يجب أن تغطي تكاليف الاستبدال والشحن في حالة حدوث خطأ.

س 3: هو أرخص جزء عادة هو أسوأ خيار? في عالم أجزاء الآلات الثقيلة, السعر المنخفض بشكل استثنائي هو دائمًا علامة حمراء. عادة ما يتم تحقيق هذه المدخرات من خلال المساومة على العوامل الحرجة: using lower-grade steel, skipping essential manufacturing steps like proper heat treatment, or having non-existent quality control. The initial savings are often quickly erased by premature failure, مما يؤدي إلى التوقف المكلف, additional labor costs, and potential damage to other components. The best value is found in parts that offer a low total cost of ownership, not the lowest purchase price.

Q4: What does ISO 9001 certification tell me about a mini excavator parts manufacturer? ISO 9001 certification indicates that the manufacturer has a documented and audited Quality Management System (نظام إدارة الجودة). It does not certify the quality of the product itself, but rather the processes the company uses to produce and deliver it. It is a positive sign that the manufacturer is committed to consistency, process control, and continuous improvement. It means they have systems for traceability, handling non-conforming products, and implementing corrective actions, which reduces the likelihood of random quality issues.

Q5: How important is the country of origin for mini excavator parts? The country of origin is less important than the manufacturer's specific quality systems, material choices, and engineering capabilities. High-quality and low-quality manufacturing can be found in almost any country. Instead of focusing on the "Made in" label, focus on the manufacturer's transparency, their technical expertise, their investment in modern machinery (like CNC and CMM), and their ability to provide verifiable proof of performance through case studies and robust warranties.

Q6: What are the most common wear parts on a mini excavator undercarriage? الهيكل السفلي هو نظام للمكونات المتحركة التي تعاني من أكثر التآكل. الأجزاء الأكثر استبدالًا هي Sprockets (الذي يقود المسار), سلاسل المسار (تتألف من الروابط, دبابيس, والبطانات), بكرات المسار (which support the machine's weight on the track), و Idlers الأمامي (التي توجه المسار والتوتر). يعتمد معدل التآكل اعتمادًا كبيرًا على التطبيق, تقنية المشغل, والظروف الأرضية.

خاتمة

يتطلب التنقل في السوق العالمية لمكونات الحفريات الصغيرة عقلية تتجاوز الفعل البسيط للشراء. إنه تمرين في المصادر الاستراتيجية, حيث الهدف هو عدم العثور على أرخص جزء, ولكن لتحديد الشريك الأكثر قيمة. يوفر إطار سبعة أسئلة الموضحة في هذا الدليل مسارًا منطقيًا لهذا التحقيق. إنه يشجع على التحول في التركيز من السعر على دلو أو أنصار إلى الطابع الأساسي للشركة المصنعة التي تنتجها.

من خلال الاستفسار عن الفروق الدقيقة في المعادن, تقوم بتقييم التزامهم بأساس الجودة. من خلال التدقيق في عمليات التصنيع ومراقبة الجودة, يمكنك قياس تفانيهم في الدقة والاتساق. التحقيق في ص&تكشف إمكانات D عن قدرتها على الابتكار وحل المشكلات. التشكيك في نهجهم في التركيب, الخدمات اللوجستية, ودعم ما بعد البيع يضيء فهمهم لحقائقك التشغيلية. أخيراً, يضمن المطالبة بالدليل التجريبي على الأداء أن قرارك يرتكز في الواقع, ليس فقط نثر التسويق.

أخيرًا, selecting a mini excavator parts manufacturer is an investment in your own fleet's reliability and profitability. إن الشراكة مع المورد الذي يمكنه الإجابة على هذه الأسئلة بثقة وشفافية هي شراكة من شأنها أن تتجاوز التكلفة الأولية للمكون. يوفر فترة التوقف المنخفض, أداء الماكينة المحسّن, وراحة البال التي تأتي من معرفة المعدات الخاصة بك مدعومة من قبل أساس التميز الهندسي والدعم الثابت.

مراجع

أبيزورور, أ., السيد, أ., عابد, م. ر., & Sghir, أ. (2021). تأثير ISO 9001 نظام إدارة الجودة على الأداء التشغيلي. المجلة الدولية للجودة & إدارة الموثوقية, 38(1), 183-204. https://doi.org/10.1108/IJQRM-11-2019-0358

ماكينات جولي. (اختصار الثاني.). ما هي بكرة المسار? تم الاسترجاع يونيو 10, 2025, من https://www.julimachinery.com/what-is-a-track-roller/

مخيف, أنا., & Donertas, م. أ. (2017). تأثير طرق المعالجة الحرارية المختلفة على الخواص الميكانيكية وسلوك ارتداء الصلب البورون. اختبار المواد, 59(5), 455-460. https://doi.org/10.3139/120.111022

كومار, س, & phrommathed, ص. (2005). تطوير منتج جديد: دراسة تجريبية لآثار استراتيجية الابتكار, التعلم منظمة وظروف السوق. مجلة إدارة الهندسة والتكنولوجيا, 22(4), 350-353.

lofts, ح. (2016). تطوير منتجات جديدة في صناعة العمليات: دراسة لآثار المشروع, حازم, وخصائص السوق. مجلة إدارة الهندسة والتكنولوجيا, 41, 30-46.

ران, ق. ب., & ثاككر, ق. الخامس. (2021). نهج متكامل لإدارة المخاطر في سلسلة التوريد العالمية للهندسة الثقيلة. مجلة الهندسة, التصميم والتكنولوجيا, 19(1), 193-219. https://doi.org/10.1108/JEDT-01-2020-0015

سارما, د. ك., & كومار, ر. (2020). تحليل الفشل من دلو حفارة الأسنان. تحليل الفشل الهندسي, 118, 104886.

سوير, ز. أ., أريكان, واو, & مرحباً, ج. (2011). نهج منطقي غامض يعتمد على تصميم أنظمة التصنيع الخلوية. أجهزة الكمبيوتر & الهندسة الصناعية, 61(4), 932-940.

هو على وشك, د., kliment, م, & بيترريك, ي. (2014). باستخدام طريقة العناصر المحدودة لتحسين عملية الحفر. هندسة الإجراءات, 96, 464-468.

تشانغ, Y., ليو, ج., & تشن, ح. (2019). دراسة عن مقاومة ارتداء أسنان دلو الحفارة على أساس التصميم البويني. مجلة الهندسة البيونية, 16(2), 336-346. https://doi.org/10.1007/s42235-019-0027-6