Abstrakt

The selection of an appropriate hydraulic track press machine represents a foundational decision for entities managing fleets of heavy construction and mining equipment. This document provides a methodical examination of the critical factors governing this choice, aimed at maximizing equipment uptime and operational efficiency. It presents a comprehensive seven-point checklist that guides professionals through the process of evaluating tonnage capacity against fleet requirements, the adaptability and quality of tooling, and the strategic choice between portable and stationary units. Further analysis extends to the intricacies of hydraulic system design, the integration of safety mechanisms and ergonomic considerations, a nuanced calculation of total cost of ownership, and the imperative of verifying supplier reputation and after-sales support. By approaching the acquisition not as a simple purchase but as a strategic investment in operational continuity, this guide equips decision-makers in markets such as Russia, Australien, Mittlerer Osten, and Southeast Asia to select a hydraulic track press machine that enhances maintenance capabilities, extends undercarriage life, and ultimately fortifies profitability.

Key Takeaways

- Match the press tonnage directly to the largest machine in your specific fleet.

- Invest in a comprehensive and durable tooling set to service all your equipment.

- Choose between stationary and portable presses based on your operational workflow.

- A reliable hydraulic track press machine is a direct investment in equipment uptime.

- Prioritize safety features to protect both operators and expensive track components.

- Analyze the total cost of ownership, nicht nur der anfängliche Kaufpreis.

- Verify supplier reputation and their capacity for long-term after-sales support.

Inhaltsverzeichnis

- A Foundational Perspective on Undercarriage Maintenance

- 1. Assessing Tonnage and Power Requirements

- 2. Evaluating Tooling and Adaptability

- 3. Determining Portability and Workshop Integration

- 4. Scrutinizing Hydraulic System Design and Reliability

- 5. Prioritizing Safety Features and Operator Ergonomics

- 6. Analyzing Total Cost of Ownership (Tco) Beyond the Sticker Price

- 7. Verifying Supplier Reputation and After-Sales Support

- Häufig gestellte Fragen (FAQ)

- A Final Consideration on Strategic Investment

- Referenzen

A Foundational Perspective on Undercarriage Maintenance

Before we can begin a meaningful discussion about the machinery used for maintenance, we must first establish a shared understanding of the subject of that maintenance: the undercarriage of tracked heavy equipment. Imagine a bulldozer or an excavator. Its ability to move across challenging terrain, to push earth or dig foundations, is entirely dependent on the complex system of steel components that meets the ground. Dieses System, the undercarriage, is akin to the legs and feet of the machine. It comprises a set of track chains, which are themselves made of interconnected links, Stifte, Buchsen, und Trackschuhe. These chains are driven by sprockets and guided by idlers and rollers. It is a system of controlled, rolling friction.

The environment in which these machines operate—be it a quarry in Australia, a construction site in the Middle East, or a pipeline project in Siberia—is inherently abrasive and unforgiving. Soil, Felsen, Sand, and debris constantly work their way into the moving parts of the undercarriage. This constant ingression of abrasive material, combined with the immense weight of the machine and the powerful forces of propulsion and turning, leads to continuous wear. The pins and bushings that connect the track links are at the epicentre of this wear. They are the joints, the knuckles of the track chain, and they bear incredible shear and rotational forces. Over hundreds and thousands of hours, the precisely machined tolerances of these parts are worn away. The "pitch," or distance between the centre of one pin to the next, begins to elongate. This is often called "track stretch." As the pitch extends, the track chain no longer meshes perfectly with the teeth of the sprocket, leading to accelerated wear on the entire system.

The financial implications of undercarriage wear are substantial. For most heavy tracked equipment, the undercarriage can account for up to 50% of the machine's total maintenance budget over its operational life (Prabowo et al., 2021). Allowing wear to proceed unchecked leads to a cascade of failures. A worn chain will destroy a new sprocket. A "stretched" track is more likely to de-track, or come off the rollers, causing immediate and costly downtime. The goal of any effective maintenance program, daher, is to manage this wear proactively. A core procedure in this program is the "pin and bushing turn." When the bushings have worn significantly on one side, they can be pressed out, rotated 180 Grad, and pressed back in to present a new wear surface, effectively doubling their service life. Eventually, both pins and bushings wear beyond service limits and must be replaced entirely.

This is where the hydraulic track press machine enters the narrative. The pins and bushings are not held in place with a simple nut and bolt. They are installed with an extreme "interference fit" or "press fit." This means the pin is slightly larger than the hole in the track link it fits into. To install it, immense force is required to momentarily deform the components so they can be assembled. Once in place, the resulting pressure creates a powerful frictional bond that prevents the pin from rotating within the link. The force required to overcome this bond and push a pin out can range from 50 tons for smaller equipment to well over 300 tons for large mining machinery. It is a task that is impossible to perform with manual tools. The hydraulic track press is the specialized instrument designed for this single, vital purpose: to safely and efficiently apply the controlled force needed to remove and install track pins and bushings. Selecting the right one is not merely a tool purchase; it is a strategic decision that directly impacts the cost, Effizienz, and safety of your entire equipment maintenance operation.

1. Assessing Tonnage and Power Requirements

The first and most fundamental point in our checklist is the evaluation of tonnage. Tonnage, in the context of a hydraulic track press machine, refers to the maximum amount of force the machine can exert. It is the measure of its raw power. Thinking about this concept requires us to move beyond a simple number and understand what that force is being used to accomplish. The selection of the correct tonnage is not a matter of choosing the biggest number; it is a precise engineering calculation that balances capability with the risk of damage.

Understanding Tonnage: The Physics of Pin Pressing

At its heart, the task of a track press is to overcome static friction and the residual forces of an interference fit. When a track pin is pressed into a track link, the outer diameter of the pin is fractionally larger than the inner diameter of the link bore. This creates immense pressure, measured in thousands of pounds per square inch, between the two surfaces. This pressure ensures the pin stays fixed in the link eye-bar during operation. To remove that pin, the press must generate enough force to break this bond and slide the pin out.

Imagine trying to push a large, tight-fitting cork into a wine bottle. Now imagine that cork is made of hardened steel, the bottle is a 50-kilogram track link, and they have been grinding against rock and sand for 2,000 Std.. Rust, Schmutz, and microscopic deformations in the metal (ärgerlich) can dramatically increase the amount of force needed, a phenomenon known as "breakaway friction." The initial force required to get the pin moving is often significantly higher than the force needed to keep it moving.

A hydraulic press accomplishes this using Pascal's principle. A pump pushes hydraulic fluid into a large cylinder, acting on a piston. Because the surface area of the piston is very large, a relatively low fluid pressure can be multiplied into a tremendous amount of output force. A 100-ton press is one that can generate a force equivalent to the weight of 100 metric tons. Understanding this helps clarify why more is not always better. Applying 200 tons of force to a pin that only requires 80 tons can cause the track link to crack or permanently deform, ruining a costly component. Umgekehrt, attempting to press a 150-ton pin with a 100-ton press will, at best, fail to do the job, and at worst, could lead to a catastrophic failure of the press's frame or hydraulic components under overload conditions.

Matching Tonnage to Your Fleet

The process of selecting the correct tonnage begins with a thorough audit of the equipment fleet you intend to service. Each model of bulldozer, Bagger, or tracked loader has a specific track chain with pins and bushings of a certain diameter and fit tolerance. Manufacturers provide service specifications that detail the required force for removal and installation. Your goal is to identify the machine in your fleet that requires the highest tonnage and select a press that comfortably exceeds that requirement, providing a safe operating margin.

Zum Beispiel, a small dozer like a Caterpillar D4 might require around 60-80 tons of force. A mid-sized excavator like a Komatsu PC200 or Hitachi ZX210 may need 100-120 Tonnen. As you move into larger equipment, the numbers climb steeply. A large dozer like a Cat D9 or Komatsu D275 will demand a press in the 150-200 ton range. Endlich, the colossal machines found in large-scale mining operations, such as a Cat D11 or a Komatsu D475, require presses capable of 250 tons or more.

To make this more concrete, consider the following table which provides a general guide. Note that these are approximations, and you must always consult the specific service manual for your machine.

| Machine Class (Example Models) | Typical Pin Diameter | Estimated Tonnage Required |

|---|---|---|

| Small Dozer/Excavator (Cat D3/D5, Komatsu PC130) | 40mm – 55mm | 60 – 100 Tonnen |

| Medium Dozer/Excavator (Cat D6/D7, Komatsu PC300) | 55mm – 70mm | 100 – 150 Tonnen |

| Large Dozer/Excavator (Cat D8/D9, Komatsu PC450) | 70mm – 85mm | 150 – 220 Tonnen |

| Mining Class Dozer (Cat D10/D11, Komatsu D375/D475) | 85mm – 100mm+ | 220 – 350+ Tonnen |

A common mistake is to purchase a press based on the average machine size in a fleet. If you have ten PC200 excavators and one D9 dozer, a 100-ton press will service 90% of your fleet, but it will be entirely useless for your largest and often most critical asset. The correct approach is to size the press for the D9, as a 200-ton press can easily service the PC200s (by regulating its hydraulic pressure downwards), but the reverse is not true.

The Risks of Mismatched Power

The consequences of getting this decision wrong are severe and extend beyond simple inefficiency. An underpowered press leads to wasted time as technicians struggle to remove a stubborn pin. This often results in unsafe workarounds, such as heating the track link with a torch to expand it. While sometimes effective, this practice can alter the temper of the hardened steel, weakening the link and making it susceptible to cracking in the future. It introduces a hidden liability into your undercarriage. Außerdem, consistently running a press at its absolute maximum rated tonnage to handle a job it is barely suited for will drastically shorten the life of its seals, Pumps, and structural components, was zu einem vorzeitigen Ausfall führt.

An overpowered press presents a different set of risks. While it can be regulated, the potential for operator error is significant. A momentary lapse in concentration or a misunderstanding of the required pressure can lead to the application of excessive force. This can "egg" the link bore, stretching the precision-machined hole into an oval shape. A link damaged in this way will never hold a new pin correctly, rendering the expensive component scrap. In the most extreme cases, applying too much force can cause a brittle failure of the cast steel link, sending shards of metal flying with incredible force—a catastrophic safety event. Deswegen, the goal is to select a machine with sufficient power for your largest tasks, a reliable pressure regulation system, and to pair it with rigorous operator training.

2. Evaluating Tooling and Adaptability

Once the fundamental question of tonnage has been addressed, the focus must shift to the tools that actually transmit that force to the workpiece. A powerful hydraulic track press machine is useless without the correct set of tooling to interface with the wide variety of track link and pin sizes found across a mixed fleet of equipment. The quality, completeness, and adaptability of the tooling package are just as important as the press itself. Thinking about tooling is like considering the socket set for a master mechanic; a powerful wrench is of little use without the right size and type of socket for the job at hand.

The Anatomy of Track Press Tooling

The tooling for a track press consists of a family of specialized, hardened steel components designed to work together to safely and accurately guide the pressing force. While designs vary between manufacturers, the core components are generally consistent.

First is the main C-frame or chassis of the press, which holds the hydraulic cylinder. The "throat" of this frame must be large enough to accommodate the tallest track link you intend to service.

Next are the adaptors and supports. These are placed on the lower arm of the press frame to securely hold the track link in place. They must match the specific profile of the link to prevent it from slipping or tilting under pressure. A tilted link can lead to the pin being pressed at an angle, damaging both the pin and the link bore.

Der pushers oder rams are the components that are attached to the end of the hydraulic cylinder and make direct contact with the pin. They must be perfectly sized to the pin's diameter. A pusher that is too small can mushroom the end of the pin, making it impossible to remove. A pusher that is too large can make contact with the track link itself, Schaden verursachen. Oft, a set includes different length pushers for the two-stage process of first breaking the pin free and then pushing it completely through the link.

Endlich, there are the Führer Und installing tools. When installing a new pin, a guide tool is often used on the receiving end to ensure the pin enters the link bore perfectly straight. This prevents shaving metal off the side of the pin or bore, which would compromise the integrity of the press fit.

Each of these components must be manufactured from high-quality, heat-treated tool steel. They are subjected to immense compressive forces and must resist chipping, knacken, or deforming. Inferior tooling made from softer steel will quickly fail, not only requiring replacement but also posing a significant safety hazard.

The Importance of a Comprehensive Tooling Kit

For any organization that operates a diverse fleet of machinery from different manufacturers (Z.B., Raupe, Komatsu, Hitachi, Volvo), a comprehensive tooling kit is not a luxury; Es ist eine Notwendigkeit. Each manufacturer often uses proprietary link designs and pin dimensions, even for machines in a similar size class. Attempting to service a Komatsu track with tooling designed for a Caterpillar machine is a recipe for failure.

A quality supplier will offer a master kit with a wide array of adaptors, pushers, and guides that are clearly labeled and organized in a sturdy storage case. The ideal kit allows your technicians to confidently service any machine that rolls into the workshop, without delay. The alternative is a chaotic scramble to find or fabricate a tool when a machine comes in for service. This leads to extended downtime, as the machine sits idle waiting for the correct tooling to be sourced.

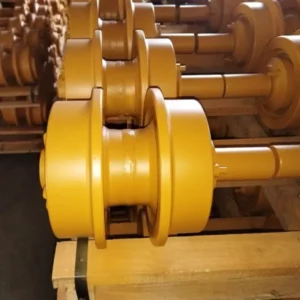

Consider the cost of a large excavator or dozer being out of commission. This can run into thousands, oder sogar Zehntausende, of dollars per day in lost productivity. Compared to this, the incremental cost of purchasing a complete tooling set at the same time as the hydraulic track press machine is negligible. It is an investment in versatility and responsiveness. When evaluating a potential press, ask the supplier for a detailed list of the included tooling. Cross-reference this list with the service requirements for every machine in your fleet. A supplier who can provide a complete, turnkey solution of both press and tooling for your specific fleet offers immense value. Diese hochwertige Fahrwerkskomponenten are the foundation of a reliable heavy equipment fleet.

Material Quality and Durability of Tooling

The adage "you get what you pay for" is particularly true when it comes to track press tooling. The difference between high-quality and low-quality tooling lies in the metallurgy and manufacturing process.

Premium tooling is typically forged from a high-carbon alloy steel, wie zum Beispiel 4140 oder 4340 chrome-molybdenum steel. After being machined to precise dimensions, it undergoes a controlled heat-treatment process. This involves heating the steel to a specific temperature, then quenching it rapidly in oil or water, followed by a tempering process (reheating to a lower temperature). This creates a component with an extremely hard surface that can resist wear and deformation, but with a slightly softer, tougher core that can absorb the shock of impact without shattering.

Im Gegensatz, cheap tooling is often made from simpler, less expensive carbon steel and may be improperly heat-treated or not heat-treated at all. Such a tool might look identical to its high-quality counterpart, but under the immense pressure of the press, it will fail. The pusher tip might deform and mushroom. The support adaptor might crack. A failure of this nature is not just an inconvenience. When a component under hundreds of tons of load fails, it can release that stored energy explosively.

When inspecting tooling, look for signs of quality manufacturing. The finish should be smooth, and the dimensions precise. The manufacturer should be able to provide detailed specifications about the material and the hardness rating (often measured on the Rockwell C scale). A reputable supplier will stand behind the quality of their tooling because they understand that it is a critical safety component. Investing in durable, properly engineered tooling from a manufacturer with a strong manufacturing history protects your technicians, prevents damage to expensive track components, and ensures that your track press is a reliable asset for years to come.

3. Determining Portability and Workshop Integration

The physical form of the hydraulic track press machine and its placement within your operational workflow is the next critical consideration. The choice is fundamentally between a large, stationary press that becomes the centerpiece of a dedicated undercarriage workshop, and a more compact, portable press designed for field service. This is not a simple question of which is "better," but rather which model aligns with your organization's maintenance philosophy and logistical realities. The decision will shape how, where, and how quickly you can respond to undercarriage service needs.

Stationary vs. Portable Presses: Eine vergleichende Analyse

Stationary and portable track presses are designed for very different contexts. A stationary press is the traditional solution for high-volume, in-depth undercarriage rebuilds. It is a large, heavy piece of equipment, often bolted to the workshop floor. Its size is an advantage, providing an extremely rigid frame that resists any flex under maximum tonnage, ensuring perfect alignment. These presses are typically paired with powered conveyor systems or overhead cranes to manipulate the heavy track chains, which can weigh several tons.

A portable press, andererseits, is designed for mobility. It features a more compact C-frame and is often mounted on a trolley or designed to be lifted by a forklift or service crane. Its power source is also mobile, usually a gasoline or diesel-powered hydraulic power unit, or it can be plumbed into the auxiliary hydraulics of a service truck. The primary advantage is the ability to take the press to the machine, rather than bringing the machine (or its tracks) to the press. This can be a game-changer for urgent repairs in remote locations, common in the mining and forestry sectors of Australia or the vast construction projects in Russia.

The following table provides a direct comparison to aid in this strategic choice:

| Besonderheit | Stationary Workshop Press | Portable Field Press |

|---|---|---|

| Power/Tonnage | Typically higher (150 – 350+ Tonnen) | Generally lower (50 – 200 Tonnen) |

| Workflow | High-efficiency for full rebuilds | Rapid response for single-point repairs |

| Portability | None; fixed installation | Hoch; can be moved to the job site |

| Infrastructure | Requires a dedicated workshop, Kräne, Leistung | Self-contained or uses service truck |

| Kosten | Higher initial investment | Lower initial investment |

| Best Use Case | Centralized maintenance depots, large fleet overhauls | Field service, emergency repairs, remote sites |

For many large organizations, the optimal solution is not an "either/or" choice but a hybrid approach. A central workshop equipped with a powerful stationary press handles the scheduled, complete track rebuilds for the entire fleet. This allows for a clean, controlled environment where quality control is high. Zusätzlich, one or more portable presses are assigned to field service teams. These units can then be dispatched to handle emergency situations, such as a broken master pin on a machine that is miles from the workshop, saving immense time and cost associated with transporting the crippled machine.

Designing the Ideal Workshop Layout

If you opt for a stationary hydraulic track press machine, its integration into the workshop is paramount for efficiency and safety. You are not just installing a tool; you are designing a workflow. The placement should be logical, minimizing the movement of extremely heavy and awkward track chains.

The process begins with a designated "dirty" area where tracks are brought in and cleaned. A high-pressure washer is essential here to remove packed dirt and grime, which can interfere with the pressing process. From there, the track should move to the press area. An overhead bridge crane or a series of jib cranes is non-negotiable for handling full track groups. The area around the press itself must be a clearly marked exclusion zone, accessible only to the trained operator.

Consider the flow of parts. There should be benches and storage for the new pins, Buchsen, Siegel, and any other Fahrwerksteile needed for the rebuild. A separate area should be designated for the worn parts that have been pressed out, ready for inspection and disposal. The layout should create a production line, even if it is a simple one: Clean -> Disassemble -> Inspect -> Assemble -> Endkontrolle. A well-designed layout, centered around a capable stationary press, can reduce the time it takes to rebuild a pair of tracks from days to hours, dramatically increasing the availability of your revenue-generating equipment.

The Logistics of Field Service with Portable Presses

The logistics of using a portable press are entirely different, focusing on self-sufficiency and adaptability. The press itself is only one part of the system. A fully equipped service truck is its life support. This truck must have a crane capable of lifting the press (which can still weigh several hundred kilograms) and positioning it onto the track of the disabled machine.

The power source is another key consideration. Many portable presses are sold with their own dedicated hydraulic power pack, typically powered by a small combustion engine. This makes the press a fully independent unit. Alternativ, the press can be run from the power take-off (PTO) hydraulic system of the service truck. This reduces the amount of equipment to be transported but makes the press dependent on that specific truck.

Safety in the field is even more challenging than in the workshop. The ground is often uneven, and the weather can be a factor. Technicians must be trained to properly stabilize the machine and the track section being worked on. Using wooden blocks or certified stands is essential to prevent any movement during the high-pressure pressing operation. In regions with extreme cold, like parts of Russia and Korea, hydraulic fluids may need to be a different viscosity, and components can become more brittle. In the hot, dusty conditions of the Middle East or Africa, preventing contamination of the hydraulic system during setup is a primary concern. The success of a field service operation hinges on meticulous planning, the right equipment, and highly skilled technicians who can adapt to challenging conditions.

4. Scrutinizing Hydraulic System Design and Reliability

At the core of any hydraulic track press machine is its hydraulic system. This is the muscle and circulatory system that translates electrical or mechanical power into the immense, controlled force required for its task. A superficial evaluation of a press might focus only on its maximum tonnage, but a more sophisticated analysis requires a deeper look into the design, Qualität, and reliability of the hydraulic components. A well-designed system is efficient, controllable, und langlebig, while a poorly designed one can be a constant source of frustration, Ausfallzeit, and safety hazards.

The Heart of the Machine: Pumps, Cylinders, and Hoses

To understand how to evaluate a hydraulic system, it helps to have a basic mental model of how it works. The process is a beautiful application of fluid dynamics, governed by Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

It begins with the hydraulic pump. This device, typically powered by an electric motor or a combustion engine, draws hydraulic fluid from a reservoir and pressurizes it. A key feature to look for in high-quality presses is a two-stage pump. This is a clever design that uses a high-volume, low-pressure gear to rapidly extend the cylinder until the pusher makes contact with the pin. This is the "approach" stage. Once the system senses resistance (pressure starting to build), it automatically switches to a low-volume, high-pressure piston stage. This allows for the slow, controlled application of maximum force needed for pressing, without wasting time moving the cylinder through its free travel.

The pressurized fluid flows through hoses and steel lines to the control valve. This is the operator's interface, allowing them to start, stop, and reverse the flow of fluid to the cylinder. The quality and rating of the hoses are paramount. They must be able to withstand pressures that can exceed 10,000 psi (700 Bar). A burst hose under this pressure is not just a leak; it is a violent, dangerous event that can inject fluid through skin.

Endlich, the fluid enters the Hydraulikzylinder. This is where the magic happens. The large surface area of the piston inside the cylinder multiplies the fluid pressure into tons of force. The quality of the cylinder's construction—the thickness of its walls, the precision of its bore, and the quality of its seals—is a direct determinant of the press's longevity and ability to hold pressure without leaking.

Key Indicators of a High-Quality Hydraulic System

When you are inspecting a potential hydraulic track press machine, you don't need to be a certified fluid power engineer to spot the indicators of quality. You can act as an informed detective, looking for clues.

Erste, examine the components. Are they from reputable, globally recognized manufacturers (Z.B., Parker, Eaton, Bosch Rexroth), or are they unbranded, generic parts? Established brands have a reputation for quality control and reliability.

Look at the hydraulic hoses. They should be clearly marked with their pressure rating, which must be appropriate for the maximum system pressure. Look for protective sheathing in areas where hoses might rub against the machine's frame. All fittings should be high-quality steel, not plated pot metal.

Überprüfen Sie die hydraulic reservoir. It should have a sight glass to easily check the fluid level and a breather cap that includes a filter to prevent airborne contaminants from entering the system. The most important, yet often overlooked, component is the hydraulic filter. A good system will have a high-quality filter, often with a pressure gauge or indicator that shows when the filter element needs to be replaced. Contamination is the number one enemy of any hydraulic system (Totten, 2000), and effective filtration is the primary defense.

Observe the Kontrollen. Are they robust and intuitive? A simple lever or button control is often more reliable and easier for operators to use safely than a complex electronic interface. The system must include a Überdruckventil. This is a critical safety device, pre-set at the factory, that prevents the system from exceeding its maximum designed pressure. It is the safety net that protects the entire system from overload.

Maintenance and Longevity of Hydraulic Components

A well-built hydraulic system, when properly maintained, can provide decades of reliable service. The total cost of ownership is significantly impacted by the ease of maintenance and the durability of its components. The maintenance philosophy should be one of proactive care rather than reactive repair.

Ein einfaches, regular maintenance schedule is the key to longevity. This is not a complex task and should be part of the operator's routine.

- Daily Visual Inspection: Before each use, the operator should walk around the machine and visually inspect all hoses and fittings for any signs of weeping, leaking, or physical damage. A small leak is a warning sign of a future failure.

- Check Hydraulic Fluid Level: The fluid level in the reservoir should be checked daily. Low fluid levels can cause the pump to cavitate (suck in air), which can quickly destroy it.

- Monitor the Filter Indicator: If the system has a filter condition indicator, it should be checked regularly. A clogged filter will starve the pump of fluid and allow dirty fluid to bypass the filter, circulating contaminants through the system.

- Follow the Recommended Service Intervals: The manufacturer will provide a schedule for changing the hydraulic fluid and the filter element. Adhering to this schedule is the single most effective thing you can do to ensure a long service life for the pump and cylinder. Hydraulic fluid does not just transmit power; it also lubricates moving parts and carries away heat. Im Laufe der Zeit, the fluid degrades and loses its protective additives.

When considering a purchase, ask the supplier about the availability and cost of common replacement parts like seal kits for the cylinder, filter elements, and hoses. A supplier who stocks these items and can provide them quickly is a valuable partner. A machine that is down for weeks waiting for a simple seal kit from overseas is not a productive asset. The reliability of the hydraulic system is a direct reflection of the manufacturer's commitment to quality engineering.

5. Prioritizing Safety Features and Operator Ergonomics

The operation of a hydraulic track press machine involves the application of immense forces. While it is a tool of immense productivity, it also carries inherent risks. A responsible approach to selecting a press must place the safety of the operator at the forefront of the decision-making process. This involves a careful examination of the engineered safety features built into the machine, as well as the ergonomic design that influences operator behavior and reduces the likelihood of error. A safe machine is a productive machine, as accidents result in the most costly form of downtime.

Engineered Safety Controls

Modern track presses should incorporate a hierarchy of safety controls designed to protect the operator and the equipment. These are not optional extras; they are fundamental design requirements.

The most important safety device is the Überdruckventil, as discussed in the previous section. It acts as the ultimate failsafe against over-pressurization, whether caused by operator error or an unexpectedly stubborn pin. You should verify that this valve is present and that it is protected from unauthorized adjustment.

Another key feature is guarding. The work area of the press, where the pin is being pushed, should be protected by a sturdy steel or polycarbonate guard. This guard contains any potential debris in the rare event of a component failure, such as a pin shattering under pressure. Some advanced systems use interlocked guards, where the press cannot be operated unless the guard is securely in place.

Der operator controls themselves are a critical safety feature. The best practice is a two-hand control system. This requires the operator to have both hands on the controls to activate the press. This simple design ensures that the operator's hands are safely away from the "danger zone" of the press ram and workpiece during the high-pressure operation. Single-lever or foot-pedal controls, while seemingly faster, significantly increase the risk of an operator having a hand or finger in the wrong place at the wrong time.

Endlich, the overall Stabilität of the machine is a safety consideration. A stationary press must be properly anchored to a solid concrete floor. A portable press must have a wide, stable base to prevent it from tipping, especially when being used on uneven ground in the field.

Ergonomics for Reduced Operator Fatigue

Ergonomics, the science of designing the workplace to fit the worker, plays a subtle but powerful role in safety and productivity. A machine that is awkward or physically demanding to use will lead to operator fatigue. A fatigued operator is far more likely to make mistakes, bypass safety procedures, or suffer a strain injury.

When evaluating a press, consider the working height. The area where the technician needs to position the track link and tooling should be at a comfortable height, typically around waist level. This minimizes the need for bending and lifting, reducing strain on the operator's back. For stationary presses, this is often achieved by mounting the press on a pedestal or by designing a recessed pit for the operator to stand in.

Think about the process of changing the tooling. How easy is it to swap out the pushers and adaptors for a different track size? A well-designed system will use quick-change pins or a simple locking mechanism. A poorly designed system might require heavy wrenches and significant physical effort, discouraging technicians from using the correct tooling for every job.

Der clarity and layout of the controls also contribute to good ergonomics. Gauges should be large, klar, and positioned in the operator's line of sight. Controls should be logically grouped and clearly labeled with universal symbols. The goal is to create an intuitive interface that reduces the cognitive load on the operator, allowing them to focus their full attention on the delicate task of pressing the pin. Good ergonomic design is a hallmark of a manufacturer that has thought deeply about how their machine will be used in the real world.

Training and Safe Operating Procedures

It is a profound truth that even the most perfectly designed machine can be operated unsafely. The final and most important layer of safety is a well-trained, competent operator. The purchase of a hydraulic track press machine must be accompanied by a commitment to comprehensive training.

A reputable supplier should offer operator training as part of the purchase package. This training should not be a brief, 10-minute overview. It should be a detailed, hands-on session covering:

- A thorough review of the machine's controls, features, and limitations.

- The correct procedure for selecting and installing the proper tooling for a given job.

- Safe techniques for lifting and handling heavy track links and chains.

- A step-by-step walkthrough of the disassembly and assembly process.

- Understanding the pressure gauge and how to apply the correct, regulated force for different pin sizes.

- Emergency shutdown procedures.

This initial training should be documented, and regular refresher training should be scheduled. Your organization should develop a formal Safe Work Procedure (SWP) or Job Safety Analysis (JSA) for the operation of the track press. This written document codifies the best practices and becomes the standard for all operators. It should be a living document, updated with any lessons learned from near-misses or incidents. By combining a well-designed machine with a culture of safety and rigorous training, you transform the hydraulic track press from a potential hazard into a cornerstone of a safe and efficient maintenance program.

6. Analyzing Total Cost of Ownership (Tco) Beyond the Sticker Price

A common pitfall in capital equipment procurement is focusing too narrowly on the initial purchase price. Ein ausgefeilterer und letztendlich profitablerer Ansatz ist die Bewertung der Gesamtbetriebskosten (Tco). The TCO is a comprehensive financial estimate that includes not only the upfront cost but also all direct and indirect costs associated with the asset over its entire lifecycle. For a hydraulic track press machine, a TCO analysis reveals that the cheapest machine is rarely the least expensive one in the long run. This analysis transforms the decision from a simple purchase to a strategic investment calculation.

Deconstructing the Initial Investment

The initial investment, or sticker price, is the most visible part of the cost, but it is itself composed of several elements. The first is the base price of the press itself. Der Zweite, and equally important, is the cost of the tooling package. Wie zuvor erläutert, a press without the right tooling is incomplete. Some suppliers may offer a low base price for the press but then charge exorbitant amounts for the necessary tooling adaptors and pushers. It is vital to evaluate the cost of a complete, functional system that can service your entire fleet.

Other upfront costs that must be factored in include shipping and freight. A large stationary press can be a significant logistical undertaking to transport, especially to remote locations in Africa or the Australian outback. Installation and commissioning costs must also be considered. Does the supplier provide a technician to oversee the installation, level the machine, and provide initial operator training? Or is that an additional cost? Endlich, any necessary facility modifications, such as pouring a new concrete pad or installing a dedicated electrical service for a stationary press, are part of the initial investment. A thorough accounting of all these elements provides the true "Day One" cost of the machine.

Factoring in Operational and Maintenance Costs

The TCO analysis truly begins to show its value when you project the costs that will be incurred over the machine's operational life, which could be 10, 20, or even more years.

Operational Costs include the consumables required to run the press. The most significant of these is the cost of electricity for an electric-powered press or fuel for one with a combustion engine. While this may seem small on a per-job basis, it can add up over thousands of hours of operation.

Instandhaltungskosten are a more significant variable and are directly related to the quality of the machine. Dazu gehören:

- Hydraulic Fluid and Filters: These need to be replaced on a regular schedule. A machine with a larger reservoir or one that requires specialized, expensive fluid will have a higher cost in this area.

- Replacement Seals: The seals in the hydraulic cylinder are wear items and will eventually need to be replaced. The cost and availability of these seal kits are an important factor.

- Replacement Tooling: Even the best quality tooling will eventually wear or can be damaged. The cost of replacing individual tooling components should be considered.

- Unscheduled Repairs: This is the great unknown. A low-quality press with generic hydraulic components is far more likely to suffer from premature pump failures, leaking valves, or cracked welds. These unexpected breakdowns not only incur repair costs (parts and labor) but also lead to costly operational downtime. A well-built machine from one of the reputable suppliers of heavy machinery parts will have significantly lower unscheduled repair costs over its lifetime.

When comparing two presses, one with a lower initial cost but built with lower-quality components, and another with a higher initial cost but built with premium, reliable components, the TCO analysis will almost invariably favor the higher-quality machine. The initial savings of the cheaper machine are often erased within a few years by higher maintenance and repair expenditures.

Calculating the Return on Investment (ROI) through Uptime

The most powerful part of the TCO analysis is calculating the financial benefit of owning the press, which allows you to determine its Return on Investment (ROI). The primary benefit of an in-house hydraulic track press machine is a dramatic reduction in equipment downtime and external repair costs.

Erste, calculate your current costs. How much do you currently spend per year sending tracks out to a specialized repair shop? This includes not only the invoice from the shop but also the cost of labor to remove the tracks, the transportation costs, and most importantly, the cost of the machine being idle during this entire period. The cost of downtime for a primary production machine like a large excavator can be staggering.

Jetzt, project the new reality with an in-house press. The repair can be done on your schedule, often overnight or on a weekend, minimizing the impact on production. The only costs are your technician's labor and the parts (new pins and bushings).

Let's consider a simplified thought experiment. Suppose the cost of downtime for your main excavator is $1,000 pro Stunde. A typical pin and bushing turn at an external shop might take the machine out of service for 48 Std. (including transport), costing you $48,000 in lost production, plus the repair bill. If you can perform the same job in-house in a single 12-hour shift, you have saved 36 Stunden Ausfallzeit, oder $36,000, on a single repair. If you perform this type of service just a few times a year across your fleet, it becomes clear that a high-quality hydraulic track press can pay for itself in a remarkably short period. The ROI is not just positive; it is often exceptionally high. The press ceases to be an expense and is revealed to be a profit-generating asset, a tool that directly contributes to the bottom line by keeping your core business running.

7. Verifying Supplier Reputation and After-Sales Support

The final point on our checklist moves beyond the physical characteristics of the machine and focuses on the partner you choose to procure it from. A hydraulic track press machine is a long-term asset, and the relationship you have with the supplier can be just as important as the steel and hydraulics of the press itself. A reputable supplier provides not just a machine, but also a guarantee of quality, a reliable source of parts, and a lifeline of technical support. Im Gegensatz, a transactional seller who disappears after the sale can leave you with an "orphan" machine that becomes a liability.

The Hallmarks of a Reputable Manufacturer

Auf einem globalen Markt, it can be challenging to distinguish between established, quality-focused manufacturers and transient trading companies. Jedoch, there are several key indicators that can help you identify a trustworthy supplier.

Industry Experience and History: How long has the company been in business? How long have they been manufacturing track presses specifically? A company with decades of experience has a proven track record and has likely refined its designs over time based on real-world customer feedback. They have a vested interest in protecting their long-standing reputation.

Transparency and Certifications: A reputable manufacturer is proud of its facilities and processes. Look for companies that are transparent about their manufacturing capabilities. Do they have ISO 9001 Zertifizierung? This international standard for quality management systems demonstrates a formal commitment to quality control, process documentation, und kontinuierliche Verbesserung. It is an independently verified sign that the company takes quality seriously.

Customer Testimonials and Case Studies: A confident supplier will be able to provide you with references from other customers, ideally ones in your industry and region. Speaking with an existing owner of the machine can provide invaluable, unbiased insights into its performance, Zuverlässigkeit, and the quality of the supplier's support.

Direct Manufacturing vs. Reselling: It is important to understand if you are dealing directly with the manufacturer or with a third-party reseller. While resellers can be valuable local partners, dealing directly with the manufacturer often provides better technical support and more competitive pricing. A company that designs, engineers, and builds its own products has a depth of knowledge that a simple reseller cannot match.

Evaluating the Availability of Spare Parts and Technical Support

A track press, like any piece of machinery, will eventually require spare parts and may encounter technical issues that require expert advice. The supplier's ability to provide this after-sales support is a critical factor in your decision, particularly for businesses operating in geographically diverse markets like Africa, Südostasien, und der Nahe Osten.

Before purchasing, ask direct questions about their support infrastructure.

- Spare Parts Inventory: Do they maintain a stock of common wear parts like seal kits, filters, and tooling? How quickly can they ship these parts to your location? A machine that is down for a month waiting for a $50 seal kit is a catastrophic failure of supply chain management.

- Technical Documentation: Does the machine come with a comprehensive set of manuals? This should include an operator's manual, a maintenance manual with service schedules, and a detailed parts manual with exploded-view diagrams and part numbers. This documentation is essential for your own technicians to perform routine maintenance and troubleshooting.

- Technical Support Access: What happens when you have a problem you cannot solve with the manual? Is there a technical support hotline or email address? Are the support staff knowledgeable engineers or just call center operators? Is support available in your time zone and language? For complex hydraulic or electrical issues, having access to an expert who can walk your technician through a diagnostic process can save days of guesswork and downtime.

A supplier who has invested in a robust after-sales support system is demonstrating a long-term commitment to their customers. They are not just selling a product; they are providing a complete service solution.

The Value of a Comprehensive Warranty

The warranty offered by the supplier is a direct statement of their confidence in the quality and durability of their product. A short, limited warranty may be a red flag, suggesting that the manufacturer does not expect the components to last.

Analyze the details of the warranty carefully.

- Duration: How long is the warranty period? A standard for quality equipment is typically 12 months, but some premium manufacturers may offer longer terms.

- Coverage: What exactly is covered? Does it cover both parts and labor? Are there exclusions for certain "wear items"? A good warranty will clearly define what is and is not included.

- Verfahren: What is the process for making a warranty claim? Is it a simple, straightforward process, or is it designed to be difficult and discouraging?

A strong, klar, and comprehensive warranty provides peace of mind. It protects your investment against premature failure due to manufacturing defects and reduces your financial risk in the initial period of ownership. It is the final piece of evidence that confirms you are partnering with a supplier who stands behind their product and is committed to your long-term success.

Häufig gestellte Fragen (FAQ)

Can I use one hydraulic track press for all my machines?

In vielen Fällen, yes, provided you select a press with sufficient tonnage and a comprehensive tooling set. The key is to identify the machine in your fleet that requires the most force (typically your largest dozer or excavator) and choose a press that meets or exceeds that requirement. A higher-tonnage press can always be regulated to provide less force for smaller tracks, but a low-tonnage press cannot service larger equipment. The versatility then comes from having the correct adaptors and pushers for each specific track model.

What is the real difference between a 100-ton and a 200-ton press?

The primary difference is the maximum force they can generate. A 100-ton press is suitable for small to medium-sized construction equipment, like excavators up to about 25 Tonnen (Z.B., PC200, ZX210). A 200-ton press is required for larger equipment, such as large dozers (Z.B., D8, D9) and excavators in the 40-50 ton class. The 200-ton press will have a more robust frame, a larger hydraulic cylinder, and often a more powerful hydraulic pump to achieve this force, making it a physically larger and more expensive machine.

How often should I perform track maintenance like a pin and bushing turn?

This is not based on a fixed time interval but on measured wear. Maintenance should be guided by regular undercarriage inspections, where a technician uses specialized tools to measure the track pitch (der Abstand zwischen den Stiften) and the external wear on the bushings. Most manufacturers provide wear charts that specify when a pin and bushing turn is recommended and when the components are worn beyond service limits and must be replaced. Performing this maintenance based on measured wear, rather than hours alone, is the most cost-effective strategy.

Is a portable track press powerful enough for large dozers?

It depends on the specific model of the portable press and the dozer. High-capacity portable presses are available that can generate up to 200 tons of force, making them fully capable of servicing large dozers like a Caterpillar D9. Jedoch, many smaller, more common portable presses are in the 50-100 ton range and would not be adequate for this task. It is essential to match the tonnage specification of the portable press to the requirements of the machine you intend to service in the field.

What are the main safety risks when operating a track press?

The primary risks involve the immense stored energy in the system. The main hazards include: being caught in the "pinch point" between the ram and the track link, injury from a high-pressure hydraulic fluid leak, and being struck by flying debris if a component (like a brittle pin or a faulty tool) shatters under load. These risks are mitigated by using a machine with two-hand controls, proper guarding, wearing appropriate personal protective equipment (especially safety glasses), and ensuring operators are thoroughly trained in safe work procedures.

How do I know if I need to replace a track pin and bushing?

You know it's time for replacement based on two main criteria. The first is "pitch extension" or "track stretch." As pins and internal bushing walls wear, the distance between links increases. This is measured with a specialized ruler or ultrasonic device. Once the pitch extends beyond the manufacturer's specified limit, the chain will no longer mesh correctly with the sprocket and must be rebuilt. The second criterion is external bushing wear. The technician measures the remaining wall thickness of the bushing. Once it wears to a certain point, it risks cracking and should be replaced. A "pin and bushing turn" is performed when the bushing is worn on one side but still has sufficient material to be rotated for a second life.

A Final Consideration on Strategic Investment

The journey through this seven-point checklist reveals a consistent theme. The selection of a hydraulic track press machine is not a simple procurement task to be delegated and decided on price alone. It is a strategic decision with far-reaching consequences for an organization's productivity, Sicherheit, und Rentabilität. Each point on the checklist—from the fundamental physics of tonnage to the nuanced value of after-sales support—urges a shift in perspective. We must see the press not as an overhead expense, but as a fundamental enabler of uptime. It is the tool that keeps multi-million-dollar excavators and bulldozers productive. By embracing a methodical, informed, and holistic evaluation process, you equip your operation with a capability that directly translates into improved machine availability, reduced maintenance costs, and a more resilient, profitable enterprise.

Referenzen

Prabowo, A. R., Muttaqie, T., Ariotedjo, M. A., & Tjahjono, T. (2021). Undercarriage’s pin and bushing failures on the excavator unit: A short review. Journal of Applied Engineering Science, 19(3), 775-782. https://doi.org/10.5937/jaes0-29656

Totten, G. E. (2000). A review of hydraulic fluid filtration. The Franklin Institute, 337(1), 27–43. https://doi.org/10.1016/s0016-0032(00)00037-1