Abstrait

The operational viability and economic efficiency of heavy construction machinery are fundamentally dependent on the durability of their undercarriage systems. This document presents a comprehensive analysis of the critical factors involved in the selection of precision forged undercarriage parts. It examines the intricate relationship between material science, méthodologies de fabrication, and application-specific engineering. The investigation delves into the metallurgical properties of steel alloys, contrasting the microstructural advantages of forging over casting. En outre, it explores the profound impact of heat treatment processes, such as quenching and tempering, on achieving the requisite balance of hardness and toughness. The analysis extends to the importance of design considerations tailored to diverse operational environments, des terrains désertiques à forte abrasion aux sites de carrières à fort impact. Le rôle de protocoles d'assurance qualité rigoureux et le calcul du coût total de possession sont articulés comme des éléments essentiels pour prendre une décision d'approvisionnement éclairée.. Ce guide constitue une ressource essentielle pour les gestionnaires de flotte, agents d'approvisionnement, et ingénieurs de maintenance cherchant à optimiser la disponibilité des machines et à prolonger la durée de vie des actifs grâce à une sélection de composants supérieure..

Plats clés à retenir

- Prioriser la composition des matériaux; les alliages d'acier de qualité supérieure améliorent directement la longévité des composants.

- Comprenez que le processus de forgeage donne un résultat plus solide., structure de grain plus durable que le moulage.

- Adaptez la conception des composants et le traitement thermique à votre environnement opérationnel spécifique.

- Sélectionnez des fournisseurs avec une assurance qualité transparente et un support de garantie robuste.

- Évaluer le coût total de possession, not just the initial price of the parts.

- Investing in quality precision forged undercarriage parts minimizes costly equipment downtime.

- Verify manufacturer certifications to ensure adherence to international quality standards.

Table des matières

- The Foundation of Performance: Why Undercarriage Integrity Matters

- Facteur 1: Material Science and Metallurgical Composition

- Facteur 2: The Precision Forging Process and Its Implications

- Facteur 3: Design and Engineering for Specific Applications

- Facteur 4: Quality Assurance and Manufacturer Reputation

- Facteur 5: Long-Term Value and Total Cost of Ownership (Coût total de possession)

- A Deeper Examination of Key Undercarriage Components

- Questions fréquemment posées (FAQ)

- Conclusion

- Références

The Foundation of Performance: Why Undercarriage Integrity Matters

The undercarriage of an excavator or dozer is its very connection to the earth. It is a complex system of moving components that bears the entire weight of the machine, along with the immense dynamic forces generated during digging, pousser, and traversing rough terrain. Think of it not as a mere set of wheels, but as the machine's foundation, skeletal structure, and muscular system all rolled into one. The failure of a single track link, roller, or sprocket does not just stop one part; it can bring a multi-ton, multi-million-dollar piece of equipment to a grinding halt. The subsequent costs are never confined to the price of a replacement part. They ripple outwards, encompassing lost productivity, project delays, operator wages for idle time, and the logistical expense of field repairs.

In regions with demanding operational tempos like the mining sectors of Australia, the expansive construction projects in the Middle East, or the resource extraction industries across Russia and Africa, the undercarriage is subjected to relentless punishment. The financial and operational health of a company can be directly tied to the resilience of these components. Pour cette raison, the choice of replacement parts transcends a simple procurement task; it becomes a strategic decision. Opting for cheaper, lower-quality cast parts might seem like a prudent short-term saving, but it often proves to be a costly error in the long run. The focus must be on durability, resilience, et performances, which are the hallmarks of precision forged undercarriage parts. Understanding what sets these superior components apart is the first step toward building a more reliable and profitable fleet.

Facteur 1: Material Science and Metallurgical Composition

The performance of any mechanical component begins at the atomic level. Before a part is ever shaped, its potential for strength, résistance à l'usure, and toughness is determined by its constituent elements. For precision forged undercarriage parts, the choice of steel is not a trivial matter; it is the very essence of their future performance. A deep appreciation for the metallurgy involved allows one to distinguish a truly robust component from an inferior one that merely looks the part.

The Role of Steel Alloys

Base iron is simply not strong enough to withstand the forces a dozer or excavator undercarriage endures. The magic happens through alloying—the process of adding specific elements to the iron to create a steel with tailored properties.

- Carbone (C): This is the most fundamental alloying element in steel. Increasing the carbon content increases the steel's hardness and its ability to be hardened through heat treatment. Cependant, trop de carbone peut rendre l'acier cassant. For undercarriage parts, a medium carbon content is typically sought, providing a good baseline for hardness without sacrificing too much toughness.

- Manganèse (MN): Manganese is a vital element that serves multiple purposes. It improves the hardenability of the steel, meaning a thicker section can be hardened more uniformly. It also contributes to strength and acts as a deoxidizer during steel production, cleaning out impurities.

- Chrome (Croisement): When one thinks of wear resistance, chromium should come to mind. It is a powerful carbide-former. Carbides are extremely hard micro-constituents within the steel's structure that act like microscopic armor against abrasive wear. Chromium also significantly enhances corrosion resistance and hardenability.

- Molybdène (MO): Molybdenum is a powerful ally to chromium. It greatly increases the steel's toughness at a given hardness level, preventing the part from becoming brittle after heat treatment. It also improves strength at elevated temperatures and helps prevent temper embrittlement, a phenomenon that can weaken parts during certain heat treatment cycles.

- Bore (B): Even in minuscule amounts, boron has a dramatic effect on increasing the hardenability of steel. This allows manufacturers to achieve desired hardness levels in heavy-duty components with less severe quenching, reducing the risk of cracking. Steels like 35MnB or 42CrMo are common choices for high-quality precision forged undercarriage parts, selected for their excellent balance of these properties.

Understanding Hardness vs. Toughness

It is a common misconception to think of hardness and toughness as the same thing. In metallurgy, they are distinct and often opposing properties, and the balance between them is paramount for undercarriage components.

- Hardness: This is the material's ability to resist surface indentation and abrasion. A high surface hardness is necessary for parts like track links and rollers to resist the grinding wear from sand, gravier, and rock. Hardness is often measured on the Rockwell C scale (HRC).

- Toughness: This is the material's ability to absorb energy and deform without fracturing. A part with low toughness is brittle, comme du verre. It might be very hard, but a sharp impact will cause it to shatter. The core of an undercarriage component needs to be tough to absorb the shock loads from the machine dropping, hitting obstacles, or turning sharply.

A perfect undercarriage part, donc, has a dual personality. It has a very hard outer "case" to fight wear and a tougher, more ductile inner "core" to resist impact and shock. Achieving this dual nature is the primary goal of the heat treatment process, que nous explorerons plus tard. Choosing a steel alloy with good hardenability is the first step to making this dual-personality possible.

The Specter of Impurities

Just as important as the elements that are intentionally added are the ones that must be rigorously excluded. Sulfur (S) and Phosphorus (P) are the two most detrimental impurities in steel for this application.

- Sulfur: Leads to the formation of manganese sulfides, which create weak points within the steel's grain structure. This can severely reduce the material's ductility and impact toughness, making it more prone to cracking under load.

- Phosphorus: Can cause a phenomenon known as "temper embrittlement," where the steel becomes brittle after being held at or slowly cooled through a specific temperature range. It also reduces overall toughness.

Reputable steel mills and forging houses go to great lengths to produce "clean" steel with extremely low levels of sulfur and phosphorus. When evaluating a supplier of precision forged undercarriage parts, inquiring about their steel sourcing and their standards for elemental purity is a mark of a discerning buyer. The presence of these impurities is an invisible flaw that can lead to catastrophic and premature failure in the field.

Facteur 2: The Precision Forging Process and Its Implications

If material selection is the choice of the clay, the manufacturing process is the work of the sculptor's hands. La méthode utilisée pour façonner l'acier à partir d'une billette brute en un maillon de chenille ou un rouleau fini a un effet profond sur sa structure interne et, par conséquent, sa solidité et sa durée de vie. C’est là que la distinction entre fonderie et forgeage ne devient plus seulement un détail technique., mais une fracture fondamentale en termes de qualité et de performance.

Forgeage vs. Fonderie: Une histoire de deux microstructures

Imaginez un bloc de bois. Il est bien plus fort dans le sens de son grain que contre lui. Le forgeage fonctionne sur un principe similaire, mais avec la structure granuleuse microscopique de l'acier. Fonderie, d'autre part, est un processus très différent.

| Fonctionnalité | Fonderie | Forgeage de précision |

|---|---|---|

| Processus | Le métal en fusion est versé dans un moule et se solidifie. | Une billette d'acier solide est chauffée et façonnée sous une immense pression à l'aide de matrices.. |

| Structure de grains | aléatoire, isotrope (mêmes propriétés dans toutes les directions). Contient souvent de la porosité. | Grains are refined and oriented to follow the shape of the part, creating continuous grain flow. |

| Internal Defects | Prone to porosity (gas bubbles), shrinkage cavities, and cold shuts. | Eliminates internal voids and porosity through compressive force. |

| Force & Toughness | Generally lower tensile strength and fatigue resistance. More brittle. | Superior tensile strength, fatigue life, and impact toughness. |

| Fiabilité | Less predictable; hidden internal defects can lead to unexpected failure. | Highly reliable and consistent part-to-part due to refined structure. |

Fonderie is like making an ice cube. You pour liquid water into a tray and it freezes into shape. The resulting crystal structure is random. De la même manière, in casting, molten steel is poured into a mold. As it cools, the grains form in a random, non-uniform pattern. This can lead to microscopic voids and a structure that is inherently weaker and more susceptible to cracking under stress.

Forgeage, en revanche, is a process of refinement. A solid billet of high-quality steel is heated to a malleable temperature (but not melted) and then pressed, hammered, or squeezed into shape between two custom dies under thousands of tons of pressure. This immense force does something remarkable to the steel's internal grain structure. It forces the grains to align and flow along the contours of the part, much like the fibers in a muscle. This "grain flow" eliminates internal voids and creates a continuous, dense structure that is exceptionally strong and resistant to fatigue and shock. A precision forged undercarriage part is, donc, inherently superior in its ability to withstand the brutal working life of heavy machinery.

The Nuances of Heat Treatment: Trempe et revenu

Forging creates the ideal grain structure, but heat treatment unlocks its full potential. This is a carefully controlled thermal process designed to create that dual personality of a hard surface and a tough core.

- Austenitizing: The forged part is heated to a precise temperature (typically around 850-950°C) where its internal crystal structure transforms into a phase called austenite. This is the starting point for hardening.

- Éteinte: Immediately after austenitizing, the part is rapidly cooled by submerging it in a medium like water, huile, or a polymer solution. This rapid cooling forces the austenite to transform into martensite, an extremely hard but also very brittle crystal structure. The speed of the quench is critical; too slow and the part won't achieve full hardness, too fast and it can crack or warp. The specific quench medium is chosen based on the steel alloy and the part's geometry.

- Tremper: A part that is only quenched is too brittle for service. It would shatter at the first significant impact. Tempering is the process of reheating the quenched part to a lower temperature (Par exemple, 200-500°C) and holding it for a specific time. This process relieves the internal stresses from quenching and allows some of the brittle martensite to transform into more ductile structures. Tempering reduces the overall hardness slightly but dramatically increases the part's toughness.

The art and science of heat treatment lie in finding the perfect tempering temperature and time to achieve the optimal balance of surface hardness for wear resistance and core toughness for impact resistance. For components like track rollers or idlers, a process called induction hardening is often used. Ici, only the outer surface of the part is rapidly heated with an induction coil and then quenched. This creates a very deep, very hard outer case while leaving the core of the part in its original, tougher state—the ultimate expression of the dual-personality principle.

Dimensional Accuracy and Surface Finish

The "precision" in precision forging is not just a marketing term. The use of advanced, computer-machined dies and powerful hydraulic presses allows for the creation of parts with very tight dimensional tolerances. This means the part is made very close to its final shape, requiring minimal post-forging machining. This has several benefits:

- Consistency: Every part is virtually identical, ensuring proper fit and function within the undercarriage assembly.

- Force: Less machining means the beneficial grain flow created during forging is preserved, especially on critical surfaces.

- Rentabilité: Reduced machining time and material waste contribute to a more efficient production process.

A smooth surface finish, free from the scale and roughness often associated with older forging methods, is also a hallmark of quality. A smoother surface reduces friction and provides a better foundation for seals, leading to longer life for components like rollers and idlers.

Facteur 3: Design and Engineering for Specific Applications

A track link is not just a track link. A component designed for a dozer working in the sandy, abrasive soils of the United Arab Emirates has different requirements from one on an excavator breaking rock in a South Korean quarry or one operating in the permafrost of Siberia. True excellence in precision forged undercarriage parts comes from engineering that acknowledges these diverse and hostile environments. The geometry, mass, and specific heat treatment profile of a part should be a direct response to its intended application.

High-Abrasion Environments (Mining in Australia, Middle Eastern Deserts)

Dans les environnements dominés par le sable, fine grit, and abrasive rock, the primary enemy is wear. The constant grinding action acts like sandpaper on every moving component of the undercarriage.

- Engineering Focus: The design priority here is maximizing surface hardness. The goal is to create a part that can withstand this relentless abrasion for as long as possible.

- Matériel & Traitement thermique: This calls for steel alloys with high chromium content to form hard chromium carbides. The heat treatment process will be tailored to produce a very high surface hardness (often in the range of 52-58 HRC) and a deep hardened case. Induction hardening is particularly effective for track rollers and idlers in these conditions, creating a deep, wear-resistant shell.

- Design Considerations: The geometry of the parts may be optimized to shed material and reduce contact areas where grit can become trapped. The design of the seals on rollers and idlers is also of paramount importance, as preventing the ingress of fine, abrasive particles is key to preventing internal destruction.

High-Impact Conditions (Quarrying, Démolition)

In a quarry or on a demolition site, the undercarriage is subjected to constant, severe shock loads. The machine may be driving over sharp, broken rock, or the entire chassis may shudder from the impact of a hydraulic hammer or a large bucket of rock being dropped.

- Engineering Focus: Ici, the priority shifts from pure hardness to toughness and impact resistance. A part that is too hard (and therefore brittle) will fail catastrophically under these shock loads.

- Matériel & Traitement thermique: While a hard wearing surface is still needed, the core toughness is the star of the show. Alloys containing molybdenum and nickel are favored for their excellent impact properties. The tempering process will be adjusted to a slightly higher temperature, sacrifier quelques points de dureté pour obtenir une augmentation significative de la ductilité et de la ténacité. L'objectif est une pièce capable de fléchir et d'absorber de l'énergie sans se fracturer..

- Design Considerations: Les géométries des pièces peuvent présenter des rayons et des congés plus généreux dans les zones à fortes contraintes pour répartir les charges et éviter les concentrations de contraintes là où des fissures pourraient se produire.. La masse globale et la section transversale de la pièce peuvent être augmentées pour fournir plus de volume afin d'absorber l'énergie d'impact..

Opérations à températures extrêmes (Gel sibérien, Chaleur Africaine)

La température introduit une autre dimension de contrainte sur le matériau. L'acier se comporte différemment lorsqu'il fait très froid ou très chaud.

- Temps froid (-20°C à -50°C): Le principal risque par temps extrêmement froid est la fracture fragile. De nombreux aciers subissent une « transition ductile à fragile »" à mesure que la température baisse. A part that is perfectly tough at 20°C could become as brittle as glass at -40°C.

- Engineering Solution: This requires selecting steel alloys with a very low ductile-to-brittle transition temperature. The addition of nickel is particularly effective in improving low-temperature toughness. Rigorous quality control to eliminate impurities like phosphorus, which can raise this transition temperature, is absolutely vital. Every batch of steel intended for these applications must be tested for its low-temperature impact strength.

- Hot Weather (40°C+ and High Operating Temps): In hot climates, the challenge is different. The steel itself can lose some of its strength and hardness as its temperature rises from ambient heat combined with the heat generated by friction.

- Engineering Solution: Molybdenum and vanadium are key alloying elements here. They help the steel retain its hardness and strength at elevated temperatures, a property known as "hot hardness." The lubrication and sealing systems are also under greater stress, so designs that promote cooling and protect seals from overheating become more important.

An insightful supplier of high-quality excavator components will not offer a one-size-fits-all solution. They will engage in a dialogue about your specific application, location, and the type of work your machines perform. This consultative approach is a strong indicator of a manufacturer who understands the deep engineering principles behind their precision forged undercarriage parts.

Facteur 4: Quality Assurance and Manufacturer Reputation

Even with the best materials and the most advanced forging processes, the final quality of an undercarriage part is only as good as the systems in place to verify it. Quality assurance (QA) is not a single step but a pervasive culture that should permeate every stage of production, from raw material inspection to final packaging. A manufacturer's reputation is built not on marketing claims, but on the verifiable consistency and reliability of its products, backed by robust support systems.

Decoding Certifications

Certifications are a way of independently verifying that a manufacturer adheres to globally recognized standards for quality management. They are a baseline indicator of a company's commitment to process control and customer satisfaction.

- ISO 9001: This is the most fundamental and widely recognized quality management standard. An ISO 9001 La certification indique que le fabricant a un système de gestion de la qualité documenté et vérifié (QMS). It implies processes are in place for things like document control, corrective actions, internal audits, and a focus on continual improvement. While it doesn't guarantee the quality of a specific part, it ensures that a framework for achieving quality exists.

- Other Relevant Standards: Depending on the industry, other certifications like ISO/TS 16949 (for automotive suppliers, which has very stringent quality requirements) or specific OEM (Fabricant d'équipement d'origine) supplier qualifications can be strong indicators of a top-tier manufacturer. A company that serves as a supplier to major machinery brands has likely passed rigorous and demanding quality audits.

When considering a supplier, ask for their certifications. A reputable company will be proud to share them. Be wary of suppliers who are vague or dismissive about their quality management credentials.

L'importance de la traçabilité et des tests par lots

Comment pouvez-vous être sûr que le maillon de chenille que vous recevez aujourd'hui a été fabriqué avec le même soin et la même qualité d'acier que celui que vous avez acheté il y a six mois.? La réponse est la traçabilité et les tests par lots.

- Traçabilité: Un système de traçabilité robuste permet à un fabricant de suivre un seul composant tout au long de son historique de production.. Chaque partie, ou au moins chaque lot de pièces, doit être marqué d'un code. Ce code renvoie à des enregistrements détaillant la chaleur spécifique de l'acier dont il provient. (avec son rapport d'analyse chimique), la date à laquelle il a été contrefait, les paramètres de son cycle de traitement thermique, et les résultats de ses tests dimensionnels et de dureté. C'est inestimable. En cas de problème sur le terrain, traceability allows the manufacturer to quickly identify the root cause and determine if other parts from the same batch might be affected.

- Batch Testing: It is not feasible to test every single part to destruction. Plutôt, manufacturers rely on systematic batch testing. From each production run, representative samples are taken and subjected to a battery of tests:

- Spectrographic Analysis: To verify the chemical composition of the steel.

- Test de dureté: To check both surface hardness and the hardness at various depths (case depth profile).

- Tensile Testing: To measure the material's ultimate strength and ductility.

- Impact Testing (Par exemple, Charpy test): To measure the material's toughness, often performed at various temperatures for parts intended for cold climates.

- Microstructural Analysis: A metallurgist will cut, polish, et graver un échantillon pour examiner sa structure granulaire au microscope, je cherche l'amende, grain uniforme d'un forgeage et d'un traitement thermique appropriés.

Un fournisseur transparent sera en mesure de fournir des rapports de tests et d’expliquer sa fréquence et ses procédures de tests.. Ces données sont la preuve objective qui soutient leurs allégations de qualité.

Évaluation des politiques de support et de garantie des fournisseurs

La relation avec un fournisseur de pièces ne doit pas prendre fin lorsque la facture est payée. The post-sale support and warranty policy are a direct reflection of the manufacturer's confidence in their own product.

- garantie: Lisez attentivement la politique de garantie. Que couvre-t-il, et pour combien de temps? Est-ce basé sur les heures de fonctionnement ou une période de temps? Quelle est la marche à suivre pour faire une réclamation? Un clair, complet, et une garantie équitable est le signe d'un fabricant qui soutient ses pièces de train de roulement forgées avec précision.. Une garantie vague ou inexistante est un signal d’alarme majeur.

- Assistance technique: Pouvez-vous parler à quelqu'un qui comprend techniquement le produit? Si vous avez une question sur l'installation, ou si vous constatez une usure inhabituelle, y a-t-il un expert disponible pour fournir des conseils? L'accès à une assistance technique compétente peut être tout aussi précieux que la pièce elle-même, surtout lors du diagnostic de problèmes complexes.

- Disponibilité et logistique: Une grande partie est inutile si vous ne pouvez pas l'obtenir quand vous en avez besoin. Evaluate the supplier's inventory levels and their logistical capabilities, spécialement pour votre région. Disposent-ils de centres de distribution pouvant desservir les marchés en Australie, Russie, ou en Asie du Sud-Est efficacement? Un fournisseur disposant d'un solide réseau logistique mondial peut réduire considérablement vos temps d'arrêt lorsqu'une pièce critique est nécessaire..

Facteur 5: Long-Term Value and Total Cost of Ownership (Coût total de possession)

Dans le monde de la machinerie lourde, le chiffre le plus dangereux sur un devis est souvent le plus bas. Une stratégie d'approvisionnement axée uniquement sur la minimisation du prix d'achat initial des pièces du train de roulement est la recette pour des difficultés financières à long terme.. Une approche plus sophistiquée et finalement plus rentable consiste à évaluer le coût total de possession. (Coût total de possession). Le TCO est une estimation financière qui aide les acheteurs à déterminer les coûts directs et indirects d'un produit sur l'ensemble de son cycle de vie.. Il révèle que le coût réel d’un composant est bien supérieur à son prix autocollant..

Au-delà du prix d'achat initial

The initial cost of a set of precision forged undercarriage parts will almost certainly be higher than that of their cast counterparts. The more complex manufacturing process, higher quality raw materials, and extensive quality control all contribute to this higher upfront investment. Cependant, this initial price is only one piece of a much larger puzzle. The TCO calculation forces us to consider all the other associated costs that a cheaper, inferior part will inevitably generate.

A TCO analysis for undercarriage parts should include:

- Prix d'achat initial: The cost of the components themselves.

- Installation Labor Cost: The cost of the mechanics' time to remove the old parts and install the new ones.

- Coût des temps d'arrêt: The revenue lost for every hour the machine is out of service.

- Durée de vie prévue: The number of operating hours the part is expected to last.

- Future Replacement Costs: The price of the next set of parts and the labor to install them.

When you factor in a longer lifespan, the cost-per-hour of a premium part often turns out to be significantly lower than that of a cheap one.

Calculating the Cost of Downtime

The cost of downtime is the most significant and often the most underestimated factor in the TCO equation. It is not a soft, abstract number; it is hard cash evaporating from the company's bottom line. How does one begin to quantify it?

Consider a 40-ton excavator working on a critical path of a construction project.

- Lost Revenue: If the machine generates, Par exemple, $200 per hour in revenue for the company, every hour it sits idle is a direct loss of $200.

- Operator & Support Costs: The operator is likely still being paid, as are any support personnel (Par exemple, truck drivers waiting for the excavator to load them). Let's say this is another $50 par heure.

- Project Penalties: Many large contracts have penalty clauses for delays. If the failure of this one machine delays the entire project, the costs can escalate into thousands or tens of thousands of dollars per day.

- Reputational Damage: Consistently failing to meet deadlines due to equipment breakdowns damages a company's reputation, making it harder to win future bids.

Let's imagine a cheap set of track chains fails after 2,500 heures, while a premium set of precision forged track chains lasts 4,000 heures. The cheap set might have saved $2,000 on the initial purchase. But it requires an extra replacement cycle within that 4,000-hour window. That extra cycle might involve 16 hours of labor ($1,200) et 16 heures d'arrêt de la machine ($3,200 rien qu'en perte de revenus). Le coût total de cette « économie »" $2,000 est maintenant une véritable perte de $2,400 ($1,200 + $3,200 – $2,000), and that's before even considering project penalties. La partie premium, malgré son coût initial plus élevé, offre un retour sur investissement bien supérieur.

La relation symbiotique avec les pratiques de maintenance

La pleine valeur des pièces de train de roulement forgées avec précision de haute qualité ne peut être réalisée que lorsqu'elles sont associées à des pratiques de maintenance assidues.. Les deux sont liés. Un composant premium peut mieux tolérer un certain degré de négligence qu’un composant bon marché, mais sa durée de vie sera encore raccourcie. Inversement, même le meilleur entretien ne peut pas sauver une pièce fabriquée à partir de matériaux de qualité inférieure.

Les pratiques de maintenance clés qui maximisent la durée de vie de votre investissement comprennent:

- Nettoyage régulier: Nettoyer périodiquement la boue, rochers, et débris du train d'atterrissage. Packed material increases weight, strain, and abrasive wear.

- Proper Track Tension: A track that is too tight causes a massive increase in friction and wear on all components. A track that is too loose can cause the machine to "de-track" and cause significant damage. Track tension should be checked and adjusted regularly according to the OEM specifications and the current working conditions.

- Inspections régulières: Visually inspecting the undercarriage daily for loose bolts, leaking seals, or unusual wear patterns. Using ultrasonic tools to measure the wear on components like track links and rollers allows for proactive planning of replacements, turning unexpected downtime into scheduled maintenance.

- Smart Operation: Training operators to minimize high-speed reverse travel, avoid unnecessarily sharp turns, and work up and down slopes rather than across them can significantly reduce undercarriage wear.

Investing in premium parts and investing in good maintenance are two sides of the same coin. Both are essential components of a strategy aimed at maximizing machine availability and profitability.

A Deeper Examination of Key Undercarriage Components

While we have discussed the undercarriage as a system, it is composed of several distinct components, each with its own unique role and wear characteristics. Understanding these individual parts helps in diagnosing wear and making informed replacement choices.

| Composant | Fonction primaire | Common Wear Patterns | Forging Benefits |

|---|---|---|---|

| Chaîne de chenille / Link Assembly | Forms the flexible "belt" that the machine runs on; connects the track shoes. | Internal pin and bushing wear; link rail wear from rollers. | Superior fatigue resistance to withstand constant flexing and tensile loads. |

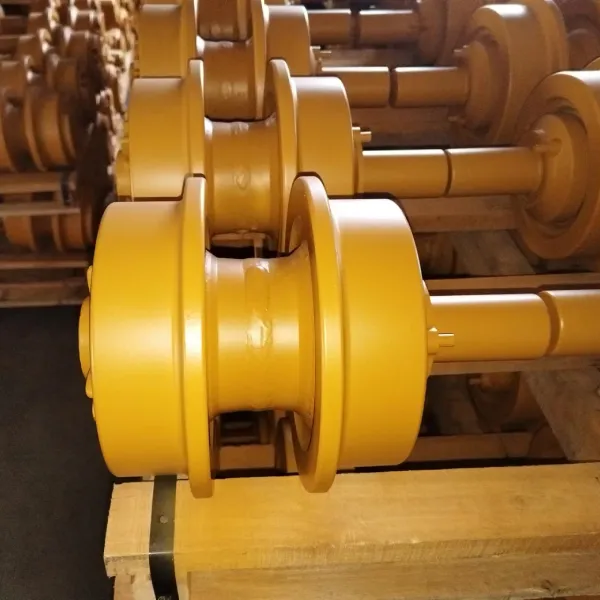

| Galets de chenille (Rouleaux inférieurs) | Support the machine's weight on the track chain. | Usure de la bride due à la rotation; usure de la bande de roulement due au contact avec les maillons. | Dureté de surface élevée pour résister à l'usure; ténacité du noyau pour résister aux impacts d'un sol accidenté. |

| Rouleaux porteurs (Rouleaux supérieurs) | Supporter le poids de la chaîne de chenille sur son chemin de retour. | Usure de la bande de roulement due à la chaîne de chenille. | Une excellente étanchéité est essentielle; le corps forgé fournit une forte, boîtier stable pour roulements et joints. |

| Pignon | S'engage avec les bagues de chenille pour entraîner la chenille. | Usure des dents, "accrochage" des dents à mesure qu'elles s'usent. | Dureté exceptionnelle sur les surfaces de contact des dents pour résister à l'usure due à l'engagement de la bague. |

| oisif | Guide la chenille à l’avant du train de roulement et est utilisée pour régler la tension de la chenille. | Usure de la bande de roulement et des boudins, semblable aux rouleaux. | Grand, la géométrie complexe bénéficie grandement de la résistance et de l'intégrité du processus de forgeage. |

Chaînes de chenilles: This is the skeleton of the track. The precision with which the pins and bushings are manufactured and heat-treated determines how long the chain maintains its correct pitch (the distance between pins). As pins and bushings wear internally, the pitch elongates, which accelerates wear on the sprocket. The links themselves must endure immense tensile forces and abrasive wear, making the refined grain structure of a forged link indispensable.

Rouleaux et rouleaux: These components live a life of constant compression and friction. Their ability to roll smoothly and resist wear is a function of their surface hardness and the quality of their internal bearings and seals. A leak in a roller seal allows abrasive grit to enter and oil to escape, leading to rapid and complete failure. The robust, dimensionally accurate body of a forged roller provides the best possible housing for these critical seals.

Pignon: The sprocket transfers the power from the final drive to the track chain. The tips of the sprocket teeth experience extremely high contact stress as they engage the track bushings. Forgeage, followed by precise induction hardening of the teeth, is the only way to create a sprocket that can withstand these forces without premature wear or tooth breakage.

By understanding the specific job of each part, one can better appreciate why a generic, one-size-fits-all approach to material and manufacturing is inadequate. Each component requires a tailored solution, and the precision forging process provides the flexibility and control to deliver that tailored solution with unparalleled strength and reliability.

Questions fréquemment posées (FAQ)

What is the most significant difference between precision forged and cast undercarriage parts? The primary difference lies in the internal grain structure of the metal. Forging kneads and aligns the steel's grain to follow the shape of the part, creating a dense, continuous structure that is significantly stronger and more resistant to shock and fatigue. Casting involves pouring molten metal into a mold, resulting in a random grain structure that can contain microscopic voids, making it more brittle and prone to unexpected failure under stress.

How does my working environment affect which undercarriage parts I should choose? Your environment is a critical factor. For highly abrasive conditions like sand or fine gravel, you need parts with maximum surface hardness to resist wear. For high-impact work like in a rock quarry, you need parts with superior core toughness to absorb shock without cracking. For extreme cold, you need parts made from specific steel alloys that resist becoming brittle at low temperatures. A good supplier will help you match the part's engineering to your specific application.

Can I mix and match undercarriage components from different manufacturers? While it is sometimes possible, it is generally not recommended. Different manufacturers may have slight variations in dimensional tolerances, spécifications matérielles, and hardness profiles. Mismatched components can lead to improper fit and accelerated wear on the entire system. Par exemple, a new, correctly pitched track chain running on a worn sprocket will cause the new chain to wear out much faster. Pour des performances et une durée de vie optimales, il est préférable d'utiliser un complet, système adapté à partir d'un seul, fabricant de haute qualité.

Un prix plus élevé pour les pièces forgées avec précision est-il toujours justifié? Lorsqu’il est évalué à travers le prisme du coût total de possession (Coût total de possession), le prix initial plus élevé est presque toujours justifié. La durée de vie prolongée et la fiabilité supérieure des pièces forgées avec précision conduisent à moins de cycles de remplacement, coûts de main d'œuvre réduits, et, le plus important, une réduction spectaculaire des temps d'arrêt coûteux des machines. La petite prime payée d'avance est un investissement qui génère des rendements importants en gardant vos machines productives et rentables..

How can I verify the quality of a potential supplier's parts? Recherchez des preuves objectives. Demandez des certifications de qualité comme ISO 9001. Renseignez-vous sur leur approvisionnement en matériaux et demandez à consulter les rapports d'analyse chimique et d'essais mécaniques pour leur acier.. Discutez de leurs processus de traitement thermique. Un fabricant réputé sera transparent et capable de fournir des données techniques détaillées pour étayer ses allégations de qualité.. Enfin, tenez compte de leur garantie et de leur niveau de support technique, car cela reflète leur confiance dans leur propre produit.

Quand dois-je prévoir de remplacer mon train de roulement? Le remplacement doit être basé sur l'usure mesurée, pas seulement sur les heures d'utilisation. Utiliser des outils spécialisés pour mesurer l'usure des axes de chenille, bagues, rails de liaison, et les brides à rouleaux vous permettent de suivre le taux d'usure et de prédire quand les composants atteindront la fin de leur durée de vie. Cette approche proactive vous permet de planifier la maintenance avant qu'une panne ne se produise, tourner un coûteux, unexpected breakdown into a planned, efficient service event.

What is the role of heat treatment in the quality of a track shoe? Heat treatment is vital for a track shoe, which needs a difficult combination of properties. The main body of the shoe needs to be tough to resist bending and cracking as it moves over uneven ground. Cependant, the grousers (the raised bars that provide traction) need to be very hard to resist abrasive wear. A process called "through-hardening" followed by careful tempering is used to achieve the necessary core toughness, ensuring the shoe can withstand the immense stresses placed upon it.

Conclusion

The selection of undercarriage parts for heavy machinery is a decision with far-reaching consequences, impacting everything from daily operational efficiency to the long-term profitability of a business. A superficial approach, guided only by the initial purchase price, overlooks the complex interplay of forces, matériels, and environments that define the working life of these components. It is a path that often leads to increased downtime, spiraling maintenance costs, and compromised project timelines.

A more enlightened path involves a deeper engagement with the principles of material science, procédés de fabrication, and application-specific engineering. By understanding the metallurgical advantages conferred by specific steel alloys, appreciating the microstructural superiority of the precision forging process, and insisting on designs tailored to the unique challenges of the operating environment, one transforms a simple purchase into a strategic investment. This approach, centered on the concept of Total Cost of Ownership, recognizes that true value lies not in the initial saving but in the extended lifespan, enhanced reliability, and sustained performance that high-quality components deliver. Finalement, choosing precision forged undercarriage parts is an affirmation of a commitment to quality, a strategy for risk mitigation, and a foundational step in building a resilient and successful heavy equipment operation.

Références

American Society for Metals. (1988). Forging and related forming processes. In Metals Handbook: Vol. 14. Forming and Forging (9l'éd.). ASM International.

Boyer, H. E. (Ed.). (1987). Atlas of heat treatment diagrams. ASM International.

Davis, J.. R. (Ed.). (2001). Alloying: Understanding the basics. ASM International. https://doi.org/10.31399/asm.tb.autb.9781627082859

Khurmi, R. S., & Gupta, J.. K. (2005). A textbook of machine design. Eurasia Publishing House.

Lange, K. (Ed.). (1985). Handbook of metal forming. McGraw-Hill.

SMI. (2021). Forging basics: The forging process. Forging Industry Association. Retrieved from

Totten, g. E. (2006). Steel heat treatment: Metallurgy and technologies. Presse CRC. https://doi.org/10.1201/9781420006463

Verma, J.. P., & Kumar, S. (2019). A review on effect of alloying elements on stainless steel. Materials Today: Proceedings, 18, 466-473.