Abstrak

The operational viability and economic efficiency of heavy construction machinery are fundamentally dependent on the durability of their undercarriage systems. This document presents a comprehensive analysis of the critical factors involved in the selection of precision forged undercarriage parts. It examines the intricate relationship between material science, Kaedah pembuatan, and application-specific engineering. The investigation delves into the metallurgical properties of steel alloys, contrasting the microstructural advantages of forging over casting. Tambahan pula, it explores the profound impact of heat treatment processes, such as quenching and tempering, on achieving the requisite balance of hardness and toughness. The analysis extends to the importance of design considerations tailored to diverse operational environments, from high-abrasion desert terrains to high-impact quarry sites. The role of stringent quality assurance protocols and the calculation of total cost of ownership are articulated as pivotal elements in making an informed procurement decision. This guide serves as an essential resource for fleet managers, procurement officers, and maintenance engineers seeking to maximize machinery uptime and extend asset lifespan through superior component selection.

Takeaways utama

- Prioritize material composition; superior steel alloys directly enhance component longevity.

- Understand that the forging process yields a stronger, more durable grain structure than casting.

- Match component design and heat treatment to your specific operational environment.

- Select suppliers with transparent quality assurance and robust warranty support.

- Menilai jumlah kos pemilikan, bukan hanya harga awal bahagian.

- Melabur dalam bahagian bawah ketepatan yang berkualiti Bahagian bawah tanah meminimumkan downtime peralatan yang mahal.

- Sahkan pensijilan pengeluar untuk memastikan kepatuhan kepada piawaian kualiti antarabangsa.

Jadual Kandungan

- Asas prestasi: Mengapa Integriti Undercarriage penting

- Faktor 1: Sains Bahan dan Komposisi Metalurgi

- Faktor 2: Proses penempaan ketepatan dan implikasinya

- Faktor 3: Reka bentuk dan kejuruteraan untuk aplikasi tertentu

- Faktor 4: Reputasi Jaminan dan Pengilang Kualiti

- Faktor 5: Nilai jangka panjang dan jumlah kos pemilikan (Tco)

- Pemeriksaan yang lebih mendalam mengenai Komponen Undercarriage Kunci

- Soalan yang sering ditanya (Soalan Lazim)

- Kesimpulan

- Rujukan

Asas prestasi: Mengapa Integriti Undercarriage penting

Undercarriage penggali atau dozer adalah sambungannya ke bumi. Ia adalah sistem komponen bergerak yang kompleks yang menanggung seluruh berat mesin, Bersama dengan kekuatan dinamik yang besar yang dihasilkan semasa menggali, menolak, dan melintasi kawasan kasar. Fikirkan ia bukan sebagai set roda semata -mata, but as the machine's foundation, Struktur rangka, dan sistem otot semuanya dilancarkan menjadi satu. Kegagalan satu pautan trek, roller, atau hancur tidak hanya menghentikan satu bahagian; ia boleh membawa pelbagai ton, peralatan berjuta-juta dolar untuk menghentikan pengisaran. Kos berikutnya tidak pernah terhad kepada harga bahagian pengganti. Mereka riak ke luar, merangkumi produktiviti yang hilang, kelewatan projek, Upah pengendali untuk masa terbiar, dan perbelanjaan logistik pembaikan lapangan.

Di kawasan yang menuntut tempos operasi seperti sektor perlombongan Australia, projek pembinaan luas di Timur Tengah, atau industri pengekstrakan sumber di seluruh Rusia dan Afrika, Pengawasan bawah tanah tertakluk kepada hukuman yang tidak henti -henti. Kesihatan kewangan dan operasi sebuah syarikat boleh terikat secara langsung dengan daya tahan komponen ini. Atas sebab ini, Pilihan bahagian pengganti melampaui tugas perolehan yang mudah; ia menjadi keputusan strategik. Memilih lebih murah, Bahagian pelakon berkualiti rendah mungkin kelihatan seperti penjimatan jangka pendek yang berhemat, Tetapi ia sering terbukti menjadi kesalahan yang mahal dalam jangka masa panjang. Tumpuan mestilah pada ketahanan, ketahanan, dan prestasi, yang merupakan ciri -ciri ketepatan bahagian bawah tanah yang dipalsukan. Memahami apa yang membezakan komponen unggul ini adalah langkah pertama ke arah membina armada yang lebih dipercayai dan menguntungkan.

Faktor 1: Sains Bahan dan Komposisi Metalurgi

Prestasi komponen mekanikal bermula pada tahap atom. Sebelum bahagian pernah dibentuk, Potensi untuk kekuatan, rintangan haus, dan ketangguhan ditentukan oleh unsur -unsur konstituennya. Untuk bahagian bawah bahagian yang dipalsukan, Pilihan keluli bukan perkara remeh; Ini adalah intipati prestasi masa depan mereka. Penghargaan yang mendalam untuk metalurgi yang terlibat membolehkan seseorang membezakan komponen yang benar -benar mantap dari yang lebih rendah yang hanya melihat bahagian.

Peranan aloi keluli

Besi asas semata -mata tidak cukup kuat untuk menahan pasukan yang bertahan di bawah penggali atau penggali. Keajaiban berlaku melalui pengaliran -proses menambahkan unsur -unsur tertentu ke besi untuk membuat keluli dengan sifat yang disesuaikan.

- Karbon (C): Ini adalah elemen pengaliran yang paling asas dalam keluli. Increasing the carbon content increases the steel's hardness and its ability to be hardened through heat treatment. Namun begitu, too much carbon can make the steel brittle. For undercarriage parts, a medium carbon content is typically sought, providing a good baseline for hardness without sacrificing too much toughness.

- Mangan (Mn): Manganese is a vital element that serves multiple purposes. It improves the hardenability of the steel, meaning a thicker section can be hardened more uniformly. It also contributes to strength and acts as a deoxidizer during steel production, cleaning out impurities.

- Chromium (Cr): When one thinks of wear resistance, chromium should come to mind. It is a powerful carbide-former. Carbides are extremely hard micro-constituents within the steel's structure that act like microscopic armor against abrasive wear. Chromium also significantly enhances corrosion resistance and hardenability.

- Molybdenum (Mo): Molybdenum is a powerful ally to chromium. It greatly increases the steel's toughness at a given hardness level, mencegah bahagian menjadi rapuh selepas rawatan haba. Ia juga meningkatkan kekuatan pada suhu tinggi dan membantu mencegah pencerobohan, fenomena yang boleh melemahkan bahagian semasa kitaran rawatan haba tertentu.

- Boron (B): Walaupun dalam jumlah minuscule, Boron mempunyai kesan dramatik untuk meningkatkan kebolehkerjaan keluli. Ini membolehkan pengeluar mencapai tahap kekerasan yang dikehendaki dalam komponen tugas berat dengan pelindapkejutan yang kurang teruk, mengurangkan risiko retak. Keluli seperti 35MNB atau 42CRMO adalah pilihan biasa untuk bahagian bawah ketepatan yang berkualiti tinggi, dipilih untuk keseimbangan yang sangat baik dari sifat -sifat ini.

Memahami kekerasan vs. Ketangguhan

Ini adalah salah tanggapan umum untuk memikirkan kekerasan dan ketangguhan sebagai perkara yang sama. Dalam metalurgi, mereka adalah sifat yang berbeza dan sering menentang, dan keseimbangan di antara mereka adalah yang paling penting untuk komponen bawah.

- Kekerasan: This is the material's ability to resist surface indentation and abrasion. Kekerasan permukaan yang tinggi diperlukan untuk bahagian -bahagian seperti pautan trek dan penggelek untuk menahan pakaian pengisaran dari pasir, Kerikil, dan batu. Kekerasan sering diukur pada skala Rockwell C (HRC).

- Ketangguhan: This is the material's ability to absorb energy and deform without fracturing. Bahagian dengan ketangguhan yang rendah adalah rapuh, seperti kaca. Mungkin sangat sukar, Tetapi kesan yang tajam akan menyebabkannya menghancurkan. Inti komponen bawah bawah perlu sukar untuk menyerap beban kejutan dari mesin yang menjatuhkan, memukul halangan, atau beralih dengan ketara.

Bahagian bawah bawah yang sempurna, oleh itu, mempunyai keperibadian ganda. Ia mempunyai kes luar yang sangat sukar "" untuk melawan pakaian dan lebih sukar, lebih banyak "teras" dalaman "" untuk menentang kesan dan kejutan. Mencapai sifat dwi ini adalah matlamat utama proses rawatan haba, yang akan kita pelajari kemudian. Memilih aloi keluli dengan kebolehkerjaan yang baik adalah langkah pertama untuk menjadikan dwi-personaliti ini mungkin.

Hantu kekotoran

Sama pentingnya dengan unsur -unsur yang sengaja ditambah adalah yang mesti dikecualikan dengan ketat. Sulfur (S) dan fosforus (P) adalah dua kekotoran yang paling memudaratkan dalam keluli untuk aplikasi ini.

- Sulfur: Membawa kepada pembentukan sulfida mangan, which create weak points within the steel's grain structure. This can severely reduce the material's ductility and impact toughness, menjadikannya lebih mudah retak di bawah beban.

- Fosforus: Boleh menyebabkan fenomena yang dikenali sebagai "pelindung suhu," di mana keluli menjadi rapuh setelah ditahan atau perlahan -lahan disejukkan melalui julat suhu tertentu. Ia juga mengurangkan ketangguhan keseluruhan.

Kilang keluli yang bereputasi dan rumah penempaan berusaha keras untuk menghasilkan "bersih" keluli dengan tahap sulfur dan fosfor yang sangat rendah. Semasa menilai pembekal bahagian bawah bahagian yang dipalsukan, Bertanya mengenai sumber keluli mereka dan piawaian mereka untuk kesucian unsur adalah tanda pembeli yang arif. Kehadiran kekotoran ini adalah kecacatan yang tidak dapat dilihat yang boleh menyebabkan kegagalan bencana dan pramatang di lapangan.

Faktor 2: Proses penempaan ketepatan dan implikasinya

Sekiranya pemilihan bahan adalah pilihan tanah liat, the manufacturing process is the work of the sculptor's hands. Kaedah yang digunakan untuk membentuk keluli dari bilet mentah ke pautan trek siap atau roller mempunyai kesan mendalam pada struktur dalamannya dan, akibatnya, kekuatan dan jangka hayatnya. Di sinilah perbezaan antara pemutus dan penempaan menjadi bukan hanya perincian teknikal, Tetapi pembahagian asas dalam kualiti dan prestasi.

Memalsukan vs. Pemutus: Kisah dua struktur mikro

Bayangkan satu blok kayu. Jauh lebih kuat sepanjang bijirinnya daripada melawannya. Memalsukan berfungsi dengan prinsip yang sama, Tetapi dengan struktur bijirin mikroskopik keluli. Pemutus, sebaliknya, adalah proses yang sangat berbeza.

| Ciri | Pemutus | Ketepatan penempaan |

|---|---|---|

| Proses | Logam cair dicurahkan ke dalam acuan dan menguatkan. | Billet keluli pepejal dipanaskan dan dibentuk di bawah tekanan besar menggunakan mati. |

| Struktur bijirin | rawak, isotropik (Sifat yang sama ke semua arah). Sering mengandungi keliangan. | Biji -bijian ditapis dan berorientasikan untuk mengikuti bentuk bahagian, Membuat aliran bijirin yang berterusan. |

| Kecacatan dalaman | Terdedah kepada keliangan (gelembung gas), Rongga pengecutan, dan penutup sejuk. | Menghapuskan lompang dalaman dan keliangan melalui daya mampatan. |

| Kekuatan & Ketangguhan | Kekuatan tegangan secara amnya lebih rendah dan rintangan keletihan. Lebih rapuh. | Kekuatan tegangan unggul, Kehidupan Keletihan, dan kesan ketangguhan. |

| Kebolehpercayaan | Kurang diramalkan; Kecacatan dalaman tersembunyi boleh menyebabkan kegagalan yang tidak dijangka. | Sebahagian daripada ke bahagian yang sangat dipercayai dan konsisten kerana struktur halus. |

Pemutus seperti membuat kiub ais. Anda mencurahkan air cair ke dalam dulang dan membeku ke dalam bentuk. Struktur kristal yang dihasilkan adalah rawak. Begitu juga, dalam pemutus, Keluli cair dicurahkan ke dalam acuan. Kerana ia sejuk, Biji -bijian membentuk secara rawak, corak tidak seragam. This can lead to microscopic voids and a structure that is inherently weaker and more susceptible to cracking under stress.

Menempa, Sebaliknya, is a process of refinement. A solid billet of high-quality steel is heated to a malleable temperature (but not melted) and then pressed, hammered, or squeezed into shape between two custom dies under thousands of tons of pressure. This immense force does something remarkable to the steel's internal grain structure. It forces the grains to align and flow along the contours of the part, much like the fibers in a muscle. This "grain flow" eliminates internal voids and creates a continuous, dense structure that is exceptionally strong and resistant to fatigue and shock. A precision forged undercarriage part is, oleh itu, inherently superior in its ability to withstand the brutal working life of heavy machinery.

The Nuances of Heat Treatment: Quenching and Tempering

Forging creates the ideal grain structure, but heat treatment unlocks its full potential. This is a carefully controlled thermal process designed to create that dual personality of a hard surface and a tough core.

- Austenitizing: The forged part is heated to a precise temperature (biasanya sekitar 850-950 ° C.) where its internal crystal structure transforms into a phase called austenite. This is the starting point for hardening.

- Pelindapkejutan: Immediately after austenitizing, the part is rapidly cooled by submerging it in a medium like water, minyak, atau penyelesaian polimer. This rapid cooling forces the austenite to transform into martensite, an extremely hard but also very brittle crystal structure. The speed of the quench is critical; too slow and the part won't achieve full hardness, Terlalu Cepat dan boleh retak atau meledingkan. The specific quench medium is chosen based on the steel alloy and the part's geometry.

- Pembiakan: Bahagian yang hanya dipadamkan terlalu rapuh untuk perkhidmatan. Ia akan menghancurkan kesan penting pertama. Pembajaan adalah proses pemanasan semula bahagian yang dipadamkan ke suhu yang lebih rendah (Mis., 200-500° C.) dan memegangnya untuk masa tertentu. Proses ini melegakan tekanan dalaman dari pelindapkejutan dan membolehkan beberapa martensit rapuh untuk berubah menjadi lebih banyak struktur mulur. Tempering reduces the overall hardness slightly but dramatically increases the part's toughness.

The art and science of heat treatment lie in finding the perfect tempering temperature and time to achieve the optimal balance of surface hardness for wear resistance and core toughness for impact resistance. For components like track rollers or idlers, a process called induction hardening is often used. Di sini, only the outer surface of the part is rapidly heated with an induction coil and then quenched. Ini mewujudkan yang sangat mendalam, very hard outer case while leaving the core of the part in its original, tougher state—the ultimate expression of the dual-personality principle.

Dimensional Accuracy and Surface Finish

The "precision" in precision forging is not just a marketing term. The use of advanced, Komputer yang muatan mati dan tekanan hidraulik yang kuat membolehkan penciptaan bahagian dengan toleransi dimensi yang sangat ketat. Ini bermaksud bahagiannya dibuat sangat dekat dengan bentuk terakhirnya, Memerlukan pemesinan pasca minimum. Ini mempunyai beberapa faedah:

- Konsistensi: Setiap bahagian hampir sama, Memastikan sesuai dan berfungsi dengan betul dalam perhimpunan bawah tanah.

- Kekuatan: Kurang pemesinan bermaksud aliran bijirin bermanfaat yang dibuat semasa penempaan dipelihara, terutamanya di permukaan kritikal.

- Keberkesanan kos: Dikurangkan masa pemesinan dan sisa bahan menyumbang kepada proses pengeluaran yang lebih cekap.

Kemasan permukaan licin, bebas dari skala dan kekasaran yang sering dikaitkan dengan kaedah penempaan yang lebih tua, juga menjadi ciri kualiti. Permukaan yang lancar mengurangkan geseran dan memberikan asas yang lebih baik untuk anjing laut, leading to longer life for components like rollers and idlers.

Faktor 3: Reka bentuk dan kejuruteraan untuk aplikasi tertentu

A track link is not just a track link. A component designed for a dozer working in the sandy, abrasive soils of the United Arab Emirates has different requirements from one on an excavator breaking rock in a South Korean quarry or one operating in the permafrost of Siberia. True excellence in precision forged undercarriage parts comes from engineering that acknowledges these diverse and hostile environments. The geometry, mass, and specific heat treatment profile of a part should be a direct response to its intended application.

High-Abrasion Environments (Mining in Australia, Middle Eastern Deserts)

Dalam persekitaran yang dikuasai oleh pasir, fine grit, and abrasive rock, the primary enemy is wear. The constant grinding action acts like sandpaper on every moving component of the undercarriage.

- Engineering Focus: The design priority here is maximizing surface hardness. The goal is to create a part that can withstand this relentless abrasion for as long as possible.

- bahan & Rawatan haba: This calls for steel alloys with high chromium content to form hard chromium carbides. The heat treatment process will be tailored to produce a very high surface hardness (often in the range of 52-58 HRC) and a deep hardened case. Induction hardening is particularly effective for track rollers and idlers in these conditions, creating a deep, wear-resistant shell.

- Design Considerations: The geometry of the parts may be optimized to shed material and reduce contact areas where grit can become trapped. The design of the seals on rollers and idlers is also of paramount importance, as preventing the ingress of fine, abrasive particles is key to preventing internal destruction.

High-Impact Conditions (Penggalian, Perobohan)

In a quarry or on a demolition site, the undercarriage is subjected to constant, severe shock loads. The machine may be driving over sharp, broken rock, or the entire chassis may shudder from the impact of a hydraulic hammer or a large bucket of rock being dropped.

- Engineering Focus: Di sini, the priority shifts from pure hardness to toughness and impact resistance. A part that is too hard (and therefore brittle) will fail catastrophically under these shock loads.

- bahan & Rawatan haba: While a hard wearing surface is still needed, the core toughness is the star of the show. Alloys containing molybdenum and nickel are favored for their excellent impact properties. The tempering process will be adjusted to a slightly higher temperature, sacrificing a few points of hardness to gain a significant increase in ductility and toughness. The goal is a part that can flex and absorb energy without fracturing.

- Design Considerations: Part geometries may feature more generous radii and fillets in high-stress areas to distribute loads and prevent stress concentrations where cracks could initiate. The overall mass and cross-section of the part might be increased to provide more bulk to absorb impact energy.

Extreme Temperature Operations (Siberian Frost, African Heat)

Temperature introduces another dimension of stress on the material. Steel behaves differently when it is very cold or very hot.

- Cold Weather (-20°C to -50°C): The primary risk in extreme cold is brittle fracture. Many steels undergo a "ductile-to-brittle transition" as the temperature drops. A part that is perfectly tough at 20°C could become as brittle as glass at -40°C.

- Engineering Solution: This requires selecting steel alloys with a very low ductile-to-brittle transition temperature. The addition of nickel is particularly effective in improving low-temperature toughness. Rigorous quality control to eliminate impurities like phosphorus, which can raise this transition temperature, is absolutely vital. Every batch of steel intended for these applications must be tested for its low-temperature impact strength.

- Hot Weather (40°C+ and High Operating Temps): In hot climates, the challenge is different. The steel itself can lose some of its strength and hardness as its temperature rises from ambient heat combined with the heat generated by friction.

- Engineering Solution: Molybdenum and vanadium are key alloying elements here. They help the steel retain its hardness and strength at elevated temperatures, a property known as "hot hardness." The lubrication and sealing systems are also under greater stress, so designs that promote cooling and protect seals from overheating become more important.

An insightful supplier of high-quality excavator components will not offer a one-size-fits-all solution. They will engage in a dialogue about your specific application, location, and the type of work your machines perform. This consultative approach is a strong indicator of a manufacturer who understands the deep engineering principles behind their precision forged undercarriage parts.

Faktor 4: Reputasi Jaminan dan Pengilang Kualiti

Even with the best materials and the most advanced forging processes, the final quality of an undercarriage part is only as good as the systems in place to verify it. Quality assurance (QA) is not a single step but a pervasive culture that should permeate every stage of production, from raw material inspection to final packaging. A manufacturer's reputation is built not on marketing claims, but on the verifiable consistency and reliability of its products, backed by robust support systems.

Decoding Certifications

Certifications are a way of independently verifying that a manufacturer adheres to globally recognized standards for quality management. They are a baseline indicator of a company's commitment to process control and customer satisfaction.

- ISO 9001: This is the most fundamental and widely recognized quality management standard. ISO 9001 pensijilan menunjukkan bahawa pengeluar mempunyai sistem pengurusan kualiti yang didokumenkan dan diaudit (Qms). Ini membayangkan proses disediakan untuk perkara seperti kawalan dokumen, tindakan pembetulan, audit dalaman, dan memberi tumpuan kepada peningkatan berterusan. While it doesn't guarantee the quality of a specific part, ia memastikan bahawa rangka kerja untuk mencapai kualiti wujud.

- Piawaian lain yang berkaitan: Bergantung pada industri, Pensijilan lain seperti ISO/TS 16949 (untuk pembekal automotif, yang mempunyai keperluan kualiti yang sangat ketat) atau OEM tertentu (Pengilang peralatan asal) Kelayakan pembekal boleh menjadi petunjuk kuat pengeluar peringkat teratas. Sebuah syarikat yang berfungsi sebagai pembekal kepada jenama jentera utama yang mungkin telah meluluskan audit yang berkualiti dan menuntut.

Semasa mempertimbangkan pembekal, Minta pensijilan mereka. Syarikat yang bereputasi akan berbangga untuk membagikannya. Be wary of suppliers who are vague or dismissive about their quality management credentials.

The Importance of Traceability and Batch Testing

How can you be sure that the track link you receive today was made with the same care and the same quality of steel as the one you bought six months ago? The answer is traceability and batch testing.

- Kebolehkesanan: A robust traceability system allows a manufacturer to track a single component all the way back through its production history. Setiap bahagian, or at least each batch of parts, should be marked with a code. This code links to records detailing the specific heat of steel it came from (with its chemical analysis report), the date it was forged, the parameters of its heat treatment cycle, and the results of its dimensional and hardness tests. This is invaluable. Should a problem ever arise in the field, traceability allows the manufacturer to quickly identify the root cause and determine if other parts from the same batch might be affected.

- Batch Testing: It is not feasible to test every single part to destruction. Sebaliknya, manufacturers rely on systematic batch testing. From each production run, representative samples are taken and subjected to a battery of tests:

- Spectrographic Analysis: To verify the chemical composition of the steel.

- Ujian kekerasan: To check both surface hardness and the hardness at various depths (case depth profile).

- Tensile Testing: To measure the material's ultimate strength and ductility.

- Impact Testing (Mis., Charpy test): To measure the material's toughness, often performed at various temperatures for parts intended for cold climates.

- Microstructural Analysis: A metallurgist will cut, polish, and etch a sample to examine its grain structure under a microscope, looking for the fine, uniform grain of a proper forging and heat treatment.

A transparent supplier will be able to provide test reports and explain their testing frequency and procedures. This data is the objective proof that stands behind their quality claims.

Evaluating Supplier Support and Warranty Policies

The relationship with a parts supplier should not end when the invoice is paid. The post-sale support and warranty policy are a direct reflection of the manufacturer's confidence in their own product.

- Waranti: Read the warranty policy carefully. What does it cover, and for how long? Is it based on operating hours or a period of time? What is the process for making a claim? A clear, comprehensive, and fair warranty is a sign of a manufacturer that stands behind their precision forged undercarriage parts. A vague or non-existent warranty is a major red flag.

- Sokongan Teknikal: Can you speak to someone who understands the product technically? If you have a question about installation, or if you experience an unusual wear pattern, is there an expert available to provide guidance? Access to knowledgeable technical support can be just as valuable as the part itself, especially when diagnosing complex issues.

- Availability and Logistics: A great part is useless if you cannot get it when you need it. Evaluate the supplier's inventory levels and their logistical capabilities, especially for your region. Do they have distribution centers that can serve markets in Australia, Rusia, or Southeast Asia efficiently? Pembekal dengan rangkaian logistik global yang kuat dapat mengurangkan downtime anda dengan ketara apabila bahagian kritikal diperlukan.

Faktor 5: Nilai jangka panjang dan jumlah kos pemilikan (Tco)

Dalam dunia jentera berat, nombor yang paling berbahaya pada sebut harga sering adalah yang paling rendah. Strategi perolehan yang difokuskan semata-mata untuk meminimumkan harga pembelian awal bahagian bawah tanah adalah resipi untuk kesakitan kewangan jangka panjang. Pendekatan yang lebih canggih dan akhirnya lebih menguntungkan adalah untuk menilai jumlah kos pemilikan (Tco). TCO adalah anggaran kewangan yang membantu pembeli menentukan kos langsung dan tidak langsung produk sepanjang kitaran hayatnya. Ia mendedahkan bahawa kos sebenar komponen jauh lebih banyak daripada harga pelekatnya.

Di luar harga pembelian awal

The initial cost of a set of precision forged undercarriage parts will almost certainly be higher than that of their cast counterparts. The more complex manufacturing process, higher quality raw materials, and extensive quality control all contribute to this higher upfront investment. Namun begitu, this initial price is only one piece of a much larger puzzle. The TCO calculation forces us to consider all the other associated costs that a cheaper, inferior part will inevitably generate.

A TCO analysis for undercarriage parts should include:

- Harga pembelian awal: The cost of the components themselves.

- Installation Labor Cost: The cost of the mechanics' time to remove the old parts and install the new ones.

- Kos downtime: The revenue lost for every hour the machine is out of service.

- Jangka Jangka Hayat: The number of operating hours the part is expected to last.

- Future Replacement Costs: The price of the next set of parts and the labor to install them.

When you factor in a longer lifespan, the cost-per-hour of a premium part often turns out to be significantly lower than that of a cheap one.

Calculating the Cost of Downtime

The cost of downtime is the most significant and often the most underestimated factor in the TCO equation. It is not a soft, abstract number; it is hard cash evaporating from the company's bottom line. How does one begin to quantify it?

Consider a 40-ton excavator working on a critical path of a construction project.

- Lost Revenue: If the machine generates, contohnya, $200 per hour in revenue for the company, every hour it sits idle is a direct loss of $200.

- Pengendali & Support Costs: The operator is likely still being paid, as are any support personnel (Mis., truck drivers waiting for the excavator to load them). Let's say this is another $50 setiap jam.

- Project Penalties: Many large contracts have penalty clauses for delays. If the failure of this one machine delays the entire project, the costs can escalate into thousands or tens of thousands of dollars per day.

- Reputational Damage: Consistently failing to meet deadlines due to equipment breakdowns damages a company's reputation, making it harder to win future bids.

Let's imagine a cheap set of track chains fails after 2,500 Jam, while a premium set of precision forged track chains lasts 4,000 Jam. The cheap set might have saved $2,000 on the initial purchase. But it requires an extra replacement cycle within that 4,000-hour window. That extra cycle might involve 16 hours of labor ($1,200) dan 16 hours of machine downtime ($3,200 in lost revenue alone). The total cost of that "saved" $2,000 is now an actual loss of $2,400 ($1,200 + $3,200 – $2,000), and that's before even considering project penalties. The premium part, despite its higher initial cost, delivers a far superior return on investment.

The Symbiotic Relationship with Maintenance Practices

The full value of high-quality precision forged undercarriage parts can only be realized when paired with diligent maintenance practices. The two are intertwined. A premium component can tolerate a degree of neglect better than a cheap one, but its lifespan will still be shortened. Sebaliknya, even the best maintenance cannot save a part made from inferior materials.

Key maintenance practices that maximize the life of your investment include:

- Pembersihan Berkala: Periodically cleaning out mud, batu, and debris from the undercarriage. Packed material increases weight, strain, and abrasive wear.

- Proper Track Tension: A track that is too tight causes a massive increase in friction and wear on all components. A track that is too loose can cause the machine to "de-track" and cause significant damage. Track tension should be checked and adjusted regularly according to the OEM specifications and the current working conditions.

- Pemeriksaan Berkala: Visually inspecting the undercarriage daily for loose bolts, leaking seals, or unusual wear patterns. Using ultrasonic tools to measure the wear on components like track links and rollers allows for proactive planning of replacements, turning unexpected downtime into scheduled maintenance.

- Smart Operation: Training operators to minimize high-speed reverse travel, avoid unnecessarily sharp turns, and work up and down slopes rather than across them can significantly reduce undercarriage wear.

Investing in premium parts and investing in good maintenance are two sides of the same coin. Both are essential components of a strategy aimed at maximizing machine availability and profitability.

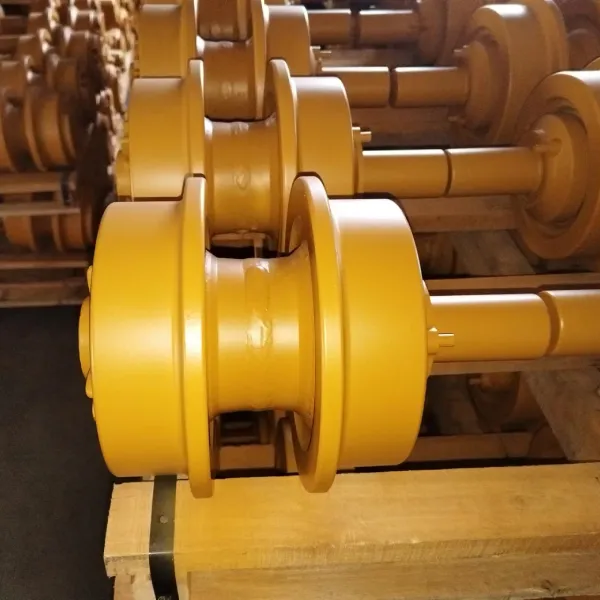

Pemeriksaan yang lebih mendalam mengenai Komponen Undercarriage Kunci

While we have discussed the undercarriage as a system, it is composed of several distinct components, each with its own unique role and wear characteristics. Understanding these individual parts helps in diagnosing wear and making informed replacement choices.

| Komponen | Primary Function | Common Wear Patterns | Forging Benefits |

|---|---|---|---|

| Rangkaian Trek / Link Assembly | Forms the flexible "belt" that the machine runs on; connects the track shoes. | Internal pin and bushing wear; link rail wear from rollers. | Superior fatigue resistance to withstand constant flexing and tensile loads. |

| Penggelek Trek (Penggelek Bawah) | Support the machine's weight on the track chain. | Flange wear from turning; tread wear from contact with the links. | High surface hardness to resist wear; core toughness to resist impact from rough ground. |

| Penggelek Pembawa (Penggelek Atas) | Support the weight of the track chain on its return path. | Tread wear from the track chain. | Excellent sealing is critical; forged body provides a strong, stable housing for bearings and seals. |

| Sproket | Engages with the track bushings to drive the track. | Tooth wear, "hooking" of teeth as they wear. | Exceptional hardness on tooth contact surfaces to resist wear from bushing engagement. |

| pemalas | Guides the track at the front of the undercarriage and is used to adjust track tension. | Tread and flange wear, similar to rollers. | Besar, complex geometry benefits greatly from the strength and integrity of the forging process. |

Rangkaian Jejak: This is the skeleton of the track. The precision with which the pins and bushings are manufactured and heat-treated determines how long the chain maintains its correct pitch (the distance between pins). As pins and bushings wear internally, the pitch elongates, which accelerates wear on the sprocket. The links themselves must endure immense tensile forces and abrasive wear, making the refined grain structure of a forged link indispensable.

Rollers dan Idler: These components live a life of constant compression and friction. Their ability to roll smoothly and resist wear is a function of their surface hardness and the quality of their internal bearings and seals. A leak in a roller seal allows abrasive grit to enter and oil to escape, leading to rapid and complete failure. The robust, badan roller yang tepat secara dimensi menyediakan perumahan yang terbaik untuk anjing laut kritikal ini.

Sproket: Sprocket memindahkan kuasa dari pemacu terakhir ke rantaian trek. Petua gigi pemancuan mengalami tekanan hubungan yang sangat tinggi kerana mereka melibatkan trek bushings. Menempa, diikuti oleh pengerasan induksi yang tepat, adalah satu -satunya cara untuk membuat gegancu yang dapat menahan daya ini tanpa memakai pramatang atau kerosakan gigi.

Dengan memahami pekerjaan khusus setiap bahagian, Seseorang dapat lebih menghargai mengapa generik, pendekatan satu-saiz-semua untuk bahan dan pembuatan tidak mencukupi. Setiap komponen memerlukan penyelesaian yang disesuaikan, dan proses penempaan ketepatan memberikan fleksibiliti dan kawalan untuk menyampaikan penyelesaian yang disesuaikan dengan kekuatan dan kebolehpercayaan yang tiada tandingannya.

Soalan yang sering ditanya (Soalan Lazim)

What is the most significant difference between precision forged and cast undercarriage parts? The primary difference lies in the internal grain structure of the metal. Forging kneads and aligns the steel's grain to follow the shape of the part, creating a dense, continuous structure that is significantly stronger and more resistant to shock and fatigue. Casting involves pouring molten metal into a mold, resulting in a random grain structure that can contain microscopic voids, making it more brittle and prone to unexpected failure under stress.

How does my working environment affect which undercarriage parts I should choose? Your environment is a critical factor. For highly abrasive conditions like sand or fine gravel, you need parts with maximum surface hardness to resist wear. For high-impact work like in a rock quarry, you need parts with superior core toughness to absorb shock without cracking. For extreme cold, you need parts made from specific steel alloys that resist becoming brittle at low temperatures. A good supplier will help you match the part's engineering to your specific application.

Can I mix and match undercarriage components from different manufacturers? While it is sometimes possible, it is generally not recommended. Different manufacturers may have slight variations in dimensional tolerances, material specifications, and hardness profiles. Mismatched components can lead to improper fit and accelerated wear on the entire system. Sebagai contoh, a new, correctly pitched track chain running on a worn sprocket will cause the new chain to wear out much faster. For optimal performance and lifespan, it is best to use a complete, matched system from a single, high-quality manufacturer.

Is a higher price for precision forged parts always justified? When evaluated through the lens of Total Cost of Ownership (Tco), the higher initial price is almost always justified. The extended lifespan and superior reliability of precision forged parts lead to fewer replacement cycles, reduced labor costs, dan, yang paling penting, a dramatic reduction in costly machine downtime. The small premium paid upfront is an investment that yields significant returns by keeping your machinery productive and profitable.

How can I verify the quality of a potential supplier's parts? Look for objective evidence. Ask for quality certifications like ISO 9001. Inquire about their material sourcing and ask to see chemical analysis and mechanical testing reports for their steel. Discuss their heat treatment processes. A reputable manufacturer will be transparent and able to provide detailed technical data to substantiate their quality claims. Akhirnya, consider their warranty and level of technical support, as this reflects their confidence in their own product.

When should I plan to replace my undercarriage? Replacement should be based on measured wear, not just on hours of use. Using specialized tools to measure the wear on track pins, bushings, link rails, and roller flanges allows you to track the wear rate and predict when components will reach the end of their service life. This proactive approach allows you to schedule maintenance before a failure occurs, turning a costly, unexpected breakdown into a planned, efficient service event.

What is the role of heat treatment in the quality of a track shoe? Heat treatment is vital for a track shoe, which needs a difficult combination of properties. The main body of the shoe needs to be tough to resist bending and cracking as it moves over uneven ground. Namun begitu, the grousers (the raised bars that provide traction) need to be very hard to resist abrasive wear. A process called "through-hardening" followed by careful tempering is used to achieve the necessary core toughness, ensuring the shoe can withstand the immense stresses placed upon it.

Kesimpulan

The selection of undercarriage parts for heavy machinery is a decision with far-reaching consequences, impacting everything from daily operational efficiency to the long-term profitability of a business. A superficial approach, guided only by the initial purchase price, overlooks the complex interplay of forces, bahan, and environments that define the working life of these components. It is a path that often leads to increased downtime, spiraling maintenance costs, and compromised project timelines.

A more enlightened path involves a deeper engagement with the principles of material science, manufacturing processes, and application-specific engineering. By understanding the metallurgical advantages conferred by specific steel alloys, appreciating the microstructural superiority of the precision forging process, and insisting on designs tailored to the unique challenges of the operating environment, one transforms a simple purchase into a strategic investment. This approach, centered on the concept of Total Cost of Ownership, mengakui bahawa nilai sebenar tidak terletak pada penjimatan awal tetapi dalam jangka hayat yang dilanjutkan, kebolehpercayaan yang dipertingkatkan, dan prestasi yang berterusan yang disampaikan oleh komponen berkualiti tinggi. Akhirnya, Memilih Ketepatan Bawah Undercarriage adalah Pengesahan komitmen terhadap kualiti, Strategi untuk Mitigasi Risiko, dan langkah asas dalam membina operasi peralatan berat yang berdaya tahan dan berjaya.

Rujukan

Persatuan Amerika untuk Logam. (1988). Proses pembentukan dan yang berkaitan. Dalam Buku Panduan Logam: Vol. 14. Membentuk dan menempa (9th ed.). ASM International.

Boyer, H. E. (Ed.). (1987). Atlas gambarajah rawatan haba. ASM International.

Davis, J. R. (Ed.). (2001). Aloi: Memahami asas -asas. ASM International. https://doi.org/10.31399/asm.tb.autb.9781627082859

Khurmi, R. S, & Gupta, J. K. (2005). Buku teks reka bentuk mesin. Eurasia Publishing House.

Lange, K. (Ed.). (1985). Buku panduan pembentukan logam. McGraw-Hill.

SMI. (2021). Memalsukan asas -asas: Proses penempaan. Memupuk Persatuan Industri. Diambil dari

TOTTER, G. E. (2006). Rawatan haba keluli: Metalurgi dan teknologi. CRC Press. https://doi.org/10.1201/9781420006463

Verma, J. P., & Kumar, S. (2019). A review on effect of alloying elements on stainless steel. Materials Today: Proceedings, 18, 466-473.