Abstract

De operationele levensvatbaarheid en economische efficiëntie van zware bouwmachines zijn fundamenteel afhankelijk van de duurzaamheid van hun onderwagensystemen. Dit document presenteert een uitgebreide analyse van de kritische factoren die betrokken zijn bij de selectie van nauwkeurig gesmede onderwagenonderdelen. Het onderzoekt de ingewikkelde relatie tussen de materiaalwetenschap, productiemethoden, en toepassingsspecifieke engineering. Het onderzoek richt zich op de metallurgische eigenschappen van staallegeringen, contrasteert de microstructurele voordelen van smeden boven gieten. Verder, het onderzoekt de diepgaande impact van warmtebehandelingsprocessen, zoals blussen en temperen, op het bereiken van de vereiste balans tussen hardheid en taaiheid. De analyse strekt zich uit tot het belang van ontwerpoverwegingen die zijn afgestemd op diverse operationele omgevingen, van woestijngebieden met hoge slijtage tot steengroeven met hoge impact. De rol van strenge kwaliteitsborgingsprotocollen en de berekening van de totale eigendomskosten worden verwoord als cruciale elementen bij het nemen van een weloverwogen aankoopbeslissing. Deze gids is een essentieel hulpmiddel voor wagenparkbeheerders, inkoopambtenaren, en onderhoudsingenieurs die de uptime van machines willen maximaliseren en de levensduur van activa willen verlengen door middel van superieure componentselectie.

Belangrijke afhaalrestaurants

- Geef prioriteit aan de materiaalsamenstelling; superieure staallegeringen verhogen direct de levensduur van de componenten.

- Begrijp dat het smeedproces een sterker resultaat oplevert, duurzamere korrelstructuur dan gieten.

- Stem het componentontwerp en de warmtebehandeling af op uw specifieke operationele omgeving.

- Selecteer leveranciers met transparante kwaliteitsborging en robuuste garantieondersteuning.

- Evalueer de totale eigendomskosten, not just the initial price of the parts.

- Investing in quality precision forged undercarriage parts minimizes costly equipment downtime.

- Verify manufacturer certifications to ensure adherence to international quality standards.

Inhoudsopgave

- The Foundation of Performance: Why Undercarriage Integrity Matters

- Factor 1: Material Science and Metallurgical Composition

- Factor 2: The Precision Forging Process and Its Implications

- Factor 3: Design and Engineering for Specific Applications

- Factor 4: Quality Assurance and Manufacturer Reputation

- Factor 5: Long-Term Value and Total Cost of Ownership (Totale eigendomskosten)

- A Deeper Examination of Key Undercarriage Components

- Veelgestelde vragen (Veelgestelde vragen)

- Conclusie

- Referenties

The Foundation of Performance: Why Undercarriage Integrity Matters

The undercarriage of an excavator or dozer is its very connection to the earth. It is a complex system of moving components that bears the entire weight of the machine, samen met de enorme dynamische krachten die tijdens het graven worden gegenereerd, duwen, en het doorkruisen van ruw terrein. Zie het niet als slechts een stel wielen, but as the machine's foundation, skeletachtige structuur, en spierstelsel allemaal in één. Het falen van een enkelspoorverbinding, rol, of het tandwiel stopt niet slechts één onderdeel; het kan een ton van meerdere tonnen opleveren, apparaat van meerdere miljoenen dollars tot stilstand gebracht. De daaropvolgende kosten beperken zich nooit tot de prijs van een vervangend onderdeel. Ze golven naar buiten, inclusief verloren productiviteit, vertragingen bij projecten, operatorlonen voor inactieve tijd, en de logistieke kosten van reparaties ter plaatse.

In regio's met veeleisende operationele tempo's, zoals de mijnbouwsectoren van Australië, de omvangrijke bouwprojecten in het Midden-Oosten, of de grondstoffenwinningsindustrieën in heel Rusland en Afrika, het onderstel wordt onderworpen aan meedogenloze straffen. De financiële en operationele gezondheid van een bedrijf kan rechtstreeks verband houden met de veerkracht van deze componenten. Om deze reden, de keuze van vervangende onderdelen overstijgt een eenvoudige inkooptaak; het wordt een strategische beslissing. Kiezen voor goedkoper, gegoten onderdelen van lagere kwaliteit lijken misschien een verstandige besparing op de korte termijn, maar op de lange termijn blijkt het vaak een kostbare fout te zijn. De focus moet liggen op duurzaamheid, weerstand, en prestaties, Dit zijn de kenmerken van nauwkeurig gesmede onderwagenonderdelen. Begrijpen wat deze superieure componenten onderscheidt, is de eerste stap op weg naar het opbouwen van een betrouwbaardere en winstgevendere vloot.

Factor 1: Material Science and Metallurgical Composition

De prestaties van elk mechanisch onderdeel beginnen op atomair niveau. Voordat een onderdeel ooit gevormd wordt, zijn potentieel voor kracht, slijtvastheid, en de taaiheid wordt bepaald door de samenstellende elementen. Voor nauwkeurig gesmede onderwagenonderdelen, de keuze voor staal is geen triviale zaak; het is de essentie van hun toekomstige prestaties. Een diepe waardering voor de betrokken metallurgie maakt het mogelijk een echt robuust onderdeel te onderscheiden van een inferieur onderdeel dat er alleen maar goed uitziet.

De rol van staallegeringen

Basisijzer is simpelweg niet sterk genoeg om de krachten te weerstaan die een onderstel van een bulldozer of graafmachine te verduren krijgt. De magie ontstaat door het legeren: het proces waarbij specifieke elementen aan het ijzer worden toegevoegd om een staal met op maat gemaakte eigenschappen te creëren.

- Koolstof (C): Dit is het meest fundamentele legeringselement in staal. Increasing the carbon content increases the steel's hardness and its ability to be hardened through heat treatment. Echter, te veel koolstof kan het staal bros maken. For undercarriage parts, a medium carbon content is typically sought, providing a good baseline for hardness without sacrificing too much toughness.

- Mangaan (Mn): Manganese is a vital element that serves multiple purposes. It improves the hardenability of the steel, meaning a thicker section can be hardened more uniformly. It also contributes to strength and acts as a deoxidizer during steel production, cleaning out impurities.

- Chroom (Cr): When one thinks of wear resistance, chromium should come to mind. It is a powerful carbide-former. Carbides are extremely hard micro-constituents within the steel's structure that act like microscopic armor against abrasive wear. Chromium also significantly enhances corrosion resistance and hardenability.

- Molybdeen (ma): Molybdenum is a powerful ally to chromium. It greatly increases the steel's toughness at a given hardness level, voorkomen dat het onderdeel na de warmtebehandeling broos wordt. Het verbetert ook de sterkte bij hoge temperaturen en helpt verbrossing door de temperatuur te voorkomen, een fenomeen dat onderdelen kan verzwakken tijdens bepaalde warmtebehandelingscycli.

- Boor (B): Zelfs in minuscule hoeveelheden, boor heeft een dramatisch effect op het vergroten van de hardbaarheid van staal. Hierdoor kunnen fabrikanten de gewenste hardheidsniveaus bereiken in componenten voor zwaar gebruik met minder ernstige afschrikking, waardoor het risico op scheuren wordt verminderd. Staalsoorten zoals 35MnB of 42CrMo zijn gebruikelijke keuzes voor hoogwaardige, nauwkeurig gesmede onderwagenonderdelen, geselecteerd vanwege hun uitstekende balans tussen deze eigenschappen.

Hardheid vs. Taaiheid

Het is een veel voorkomende misvatting om hardheid en taaiheid als hetzelfde te beschouwen. In de metallurgie, het zijn verschillende en vaak tegengestelde eigenschappen, en de balans daartussen is van het grootste belang voor onderwagencomponenten.

- Hardheid: This is the material's ability to resist surface indentation and abrasion. Een hoge oppervlaktehardheid is nodig voor onderdelen zoals rupsschakels en rollen om de slijpslijtage door zand te weerstaan, grind, en rots. Hardheid wordt vaak gemeten op de Rockwell C-schaal (HRC).

- Taaiheid: This is the material's ability to absorb energy and deform without fracturing. Een onderdeel met een lage taaiheid is bros, zoals glas. Het kan heel moeilijk zijn, maar een scherpe impact zal ervoor zorgen dat het versplintert. De kern van een onderwagenonderdeel moet sterk zijn om de schokbelastingen als gevolg van het vallen van de machine te absorberen, obstakels raken, of scherp draaien.

Een perfect ondersteldeel, daarom, heeft een dubbele persoonlijkheid. Het heeft een zeer harde buitenbehuizing" to fight wear and a tougher, more ductile inner "core" to resist impact and shock. Achieving this dual nature is the primary goal of the heat treatment process, die we later zullen verkennen. Choosing a steel alloy with good hardenability is the first step to making this dual-personality possible.

The Specter of Impurities

Just as important as the elements that are intentionally added are the ones that must be rigorously excluded. Sulfur (S) and Phosphorus (P) are the two most detrimental impurities in steel for this application.

- Sulfur: Leads to the formation of manganese sulfides, which create weak points within the steel's grain structure. This can severely reduce the material's ductility and impact toughness, making it more prone to cracking under load.

- Phosphorus: Can cause a phenomenon known as "temper embrittlement," waarbij het staal bros wordt nadat het op een bepaald temperatuurbereik is gehouden of langzaam is afgekoeld. Het vermindert ook de algehele taaiheid.

Gerenommeerde staalfabrieken en smederijen doen er alles aan om ‘schoon’ te produceren" staal met extreem lage zwavel- en fosforgehalten. Bij het beoordelen van een leverancier van nauwkeurig gesmede onderwagenonderdelen, informeren naar hun staalinkoop en hun normen voor elementaire zuiverheid is een kenmerk van een veeleisende koper. De aanwezigheid van deze onzuiverheden is een onzichtbare fout die kan leiden tot catastrofale en voortijdige storingen in het veld.

Factor 2: The Precision Forging Process and Its Implications

Als materiaalkeuze is het de keuze van de klei, the manufacturing process is the work of the sculptor's hands. The method used to shape the steel from a raw billet into a finished track link or roller has a profound effect on its internal structure and, vervolgens, its strength and lifespan. This is where the distinction between casting and forging becomes not just a technical detail, but a fundamental divide in quality and performance.

Smeden versus. Gieten: Een verhaal over twee microstructuren

Imagine a block of wood. It is far stronger along its grain than against it. Forging works on a similar principle, but with the microscopic grain structure of steel. Gieten, aan de andere kant, is a very different process.

| Functie | Gieten | Precision Forging |

|---|---|---|

| Proces | Molten metal is poured into a mold and solidifies. | A solid steel billet is heated and shaped under immense pressure using dies. |

| Korrelstructuur | Random, isotropic (same properties in all directions). Often contains porosity. | Grains are refined and oriented to follow the shape of the part, creating continuous grain flow. |

| Internal Defects | Prone to porosity (gas bubbles), krimpholtes, and cold shuts. | Eliminates internal voids and porosity through compressive force. |

| Kracht & Taaiheid | Generally lower tensile strength and fatigue resistance. More brittle. | Superior tensile strength, fatigue life, en slagvastheid. |

| Betrouwbaarheid | Less predictable; hidden internal defects can lead to unexpected failure. | Highly reliable and consistent part-to-part due to refined structure. |

Gieten is like making an ice cube. You pour liquid water into a tray and it freezes into shape. The resulting crystal structure is random. Op dezelfde manier, in casting, molten steel is poured into a mold. As it cools, the grains form in a random, non-uniform pattern. This can lead to microscopic voids and a structure that is inherently weaker and more susceptible to cracking under stress.

Smeden, in tegenstelling, is a process of refinement. A solid billet of high-quality steel is heated to a malleable temperature (but not melted) and then pressed, hammered, or squeezed into shape between two custom dies under thousands of tons of pressure. This immense force does something remarkable to the steel's internal grain structure. It forces the grains to align and flow along the contours of the part, much like the fibers in a muscle. Deze "graanstroom" eliminates internal voids and creates a continuous, dense structure that is exceptionally strong and resistant to fatigue and shock. A precision forged undercarriage part is, daarom, inherent superieur in zijn vermogen om de brute levensduur van zware machines te weerstaan.

De nuances van warmtebehandeling: Afschrikken en temperen

Door smeden ontstaat de ideale korrelstructuur, maar warmtebehandeling ontgrendelt zijn volledige potentieel. Dit is een zorgvuldig gecontroleerd thermisch proces dat is ontworpen om de dubbele persoonlijkheid van een hard oppervlak en een harde kern te creëren.

- Austenitiserend: Het gesmede onderdeel wordt tot een nauwkeurige temperatuur verwarmd (typisch rond 850-950°C) waar de interne kristalstructuur verandert in een fase die austeniet wordt genoemd. Dit is het startpunt voor verharding.

- Afschrikken: Onmiddellijk na austenitiseren, het onderdeel wordt snel gekoeld door het onder te dompelen in een medium zoals water, olie, of een polymeeroplossing. Deze snelle afkoeling dwingt het austeniet om te transformeren in martensiet, een extreem harde maar ook zeer broze kristalstructuur. The speed of the quench is critical; too slow and the part won't achieve full hardness, too fast and it can crack or warp. The specific quench medium is chosen based on the steel alloy and the part's geometry.

- Temperen: A part that is only quenched is too brittle for service. It would shatter at the first significant impact. Tempering is the process of reheating the quenched part to a lower temperature (Bijv., 200-500°C) en deze gedurende een bepaalde tijd vasthouden. This process relieves the internal stresses from quenching and allows some of the brittle martensite to transform into more ductile structures. Tempering reduces the overall hardness slightly but dramatically increases the part's toughness.

De kunst en wetenschap van warmtebehandeling ligt in het vinden van de perfecte ontlaattemperatuur en -tijd om de optimale balans te bereiken tussen oppervlaktehardheid voor slijtvastheid en kerntaaiheid voor slagvastheid. Voor componenten zoals looprollen of looprollen, een proces genaamd inductie verharding wordt vaak gebruikt. Hier, alleen het buitenoppervlak van het onderdeel wordt snel verwarmd met een inductiespoel en vervolgens geblust. Hierdoor ontstaat er een zeer diepe, zeer harde buitenbehuizing terwijl de kern van het onderdeel in zijn origineel blijft, Een hardere staat – de ultieme uitdrukking van het principe van de dubbele persoonlijkheid.

Maatnauwkeurigheid en oppervlakteafwerking

De "precisie" bij precisiesmeden is niet alleen een marketingterm. Het gebruik van geavanceerde, computergestuurde matrijzen en krachtige hydraulische persen maken het mogelijk onderdelen te maken met zeer nauwe maattoleranties. Dit betekent dat het onderdeel zeer dicht bij zijn uiteindelijke vorm wordt gemaakt, waarvoor minimale bewerking na het smeden nodig is. Dit heeft verschillende voordelen:

- Samenhang: Elk onderdeel is vrijwel identiek, zorgen voor een goede pasvorm en werking binnen het onderstel.

- Kracht: Minder bewerking betekent dat de gunstige graanstroom die tijdens het smeden ontstaat, behouden blijft, vooral op kritische oppervlakken.

- Kosten efficiëntie: Verminderde bewerkingstijd en materiaalverspilling dragen bij aan een efficiënter productieproces.

Een gladde oppervlakteafwerking, vrij van de schaal en ruwheid die vaak wordt geassocieerd met oudere smeedmethoden, is ook een kenmerk van kwaliteit. Een gladder oppervlak vermindert wrijving en biedt een betere basis voor afdichtingen, leading to longer life for components like rollers and idlers.

Factor 3: Design and Engineering for Specific Applications

A track link is not just a track link. A component designed for a dozer working in the sandy, abrasive soils of the United Arab Emirates has different requirements from one on an excavator breaking rock in a South Korean quarry or one operating in the permafrost of Siberia. True excellence in precision forged undercarriage parts comes from engineering that acknowledges these diverse and hostile environments. The geometry, mass, and specific heat treatment profile of a part should be a direct response to its intended application.

High-Abrasion Environments (Mining in Australia, Middle Eastern Deserts)

In omgevingen gedomineerd door zand, fine grit, and abrasive rock, the primary enemy is wear. The constant grinding action acts like sandpaper on every moving component of the undercarriage.

- Engineering Focus: The design priority here is maximizing surface hardness. The goal is to create a part that can withstand this relentless abrasion for as long as possible.

- Materiaal & Warmtebehandeling: This calls for steel alloys with high chromium content to form hard chromium carbides. The heat treatment process will be tailored to produce a very high surface hardness (often in the range of 52-58 HRC) and a deep hardened case. Induction hardening is particularly effective for track rollers and idlers in these conditions, creating a deep, wear-resistant shell.

- Design Considerations: The geometry of the parts may be optimized to shed material and reduce contact areas where grit can become trapped. The design of the seals on rollers and idlers is also of paramount importance, as preventing the ingress of fine, abrasive particles is key to preventing internal destruction.

High-Impact Conditions (Delfstoffen, Sloop)

In a quarry or on a demolition site, the undercarriage is subjected to constant, severe shock loads. The machine may be driving over sharp, broken rock, or the entire chassis may shudder from the impact of a hydraulic hammer or a large bucket of rock being dropped.

- Engineering Focus: Hier, the priority shifts from pure hardness to toughness and impact resistance. A part that is too hard (and therefore brittle) will fail catastrophically under these shock loads.

- Materiaal & Warmtebehandeling: While a hard wearing surface is still needed, the core toughness is the star of the show. Alloys containing molybdenum and nickel are favored for their excellent impact properties. The tempering process will be adjusted to a slightly higher temperature, sacrificing a few points of hardness to gain a significant increase in ductility and toughness. The goal is a part that can flex and absorb energy without fracturing.

- Design Considerations: Part geometries may feature more generous radii and fillets in high-stress areas to distribute loads and prevent stress concentrations where cracks could initiate. The overall mass and cross-section of the part might be increased to provide more bulk to absorb impact energy.

Extreme Temperature Operations (Siberian Frost, African Heat)

Temperature introduces another dimension of stress on the material. Steel behaves differently when it is very cold or very hot.

- Cold Weather (-20°C to -50°C): The primary risk in extreme cold is brittle fracture. Many steels undergo a "ductile-to-brittle transition" as the temperature drops. A part that is perfectly tough at 20°C could become as brittle as glass at -40°C.

- Engineering Solution: This requires selecting steel alloys with a very low ductile-to-brittle transition temperature. The addition of nickel is particularly effective in improving low-temperature toughness. Rigorous quality control to eliminate impurities like phosphorus, which can raise this transition temperature, is absolutely vital. Every batch of steel intended for these applications must be tested for its low-temperature impact strength.

- Hot Weather (40°C+ and High Operating Temps): In hot climates, the challenge is different. The steel itself can lose some of its strength and hardness as its temperature rises from ambient heat combined with the heat generated by friction.

- Engineering Solution: Molybdeen en vanadium zijn hierbij de belangrijkste legeringselementen. Ze helpen het staal zijn hardheid en sterkte te behouden bij hoge temperaturen, een eigenschap die bekend staat als "hete hardheid"." Ook de smeer- en afdichtingssystemen staan onder grotere druk, dus ontwerpen die koeling bevorderen en afdichtingen beschermen tegen oververhitting worden belangrijker.

Een inzichtelijke leverancier van hoogwaardige graafmachinecomponenten zal geen one-size-fits-all oplossing bieden. Zij gaan de dialoog aan over uw specifieke toepassing, locatie, en het soort werk dat uw machines uitvoeren. Deze adviserende aanpak is een sterke indicator voor een fabrikant die de diepgaande technische principes achter hun nauwkeurig gesmede onderwagenonderdelen begrijpt.

Factor 4: Quality Assurance and Manufacturer Reputation

Zelfs met de beste materialen en de meest geavanceerde smeedprocessen, de uiteindelijke kwaliteit van een onderstelonderdeel is slechts zo goed als de systemen die aanwezig zijn om dit te verifiëren. Kwaliteitsborging (QA) is niet één enkele stap, maar een diepgaande cultuur die in elke productiefase zou moeten doordringen, van grondstofinspectie tot eindverpakking. A manufacturer's reputation is built not on marketing claims, maar op de verifieerbare consistentie en betrouwbaarheid van haar producten, ondersteund door robuuste ondersteuningssystemen.

Decoderingscertificeringen

Certificeringen zijn een manier om onafhankelijk te verifiëren dat een fabrikant zich houdt aan wereldwijd erkende normen voor kwaliteitsmanagement. They are a baseline indicator of a company's commitment to process control and customer satisfaction.

- ISO 9001: Dit is de meest fundamentele en algemeen erkende standaard voor kwaliteitsmanagement. Een ISO 9001 certification indicates that the manufacturer has a documented and audited Quality Management System (QMS). It implies processes are in place for things like document control, corrective actions, internal audits, and a focus on continual improvement. While it doesn't guarantee the quality of a specific part, it ensures that a framework for achieving quality exists.

- Other Relevant Standards: Depending on the industry, other certifications like ISO/TS 16949 (for automotive suppliers, which has very stringent quality requirements) or specific OEM (Originele fabrikant van apparatuur) supplier qualifications can be strong indicators of a top-tier manufacturer. A company that serves as a supplier to major machinery brands has likely passed rigorous and demanding quality audits.

When considering a supplier, ask for their certifications. A reputable company will be proud to share them. Be wary of suppliers who are vague or dismissive about their quality management credentials.

The Importance of Traceability and Batch Testing

How can you be sure that the track link you receive today was made with the same care and the same quality of steel as the one you bought six months ago? The answer is traceability and batch testing.

- Traceerbaarheid: A robust traceability system allows a manufacturer to track a single component all the way back through its production history. Elk deel, or at least each batch of parts, should be marked with a code. This code links to records detailing the specific heat of steel it came from (with its chemical analysis report), the date it was forged, the parameters of its heat treatment cycle, and the results of its dimensional and hardness tests. This is invaluable. Should a problem ever arise in the field, traceability allows the manufacturer to quickly identify the root cause and determine if other parts from the same batch might be affected.

- Batch Testing: It is not feasible to test every single part to destruction. In plaats van, manufacturers rely on systematic batch testing. From each production run, representative samples are taken and subjected to a battery of tests:

- Spectrographic Analysis: To verify the chemical composition of the steel.

- Hardheid testen: To check both surface hardness and the hardness at various depths (case depth profile).

- Tensile Testing: To measure the material's ultimate strength and ductility.

- Impact Testing (Bijv., Charpy test): To measure the material's toughness, often performed at various temperatures for parts intended for cold climates.

- Microstructural Analysis: A metallurgist will cut, polish, and etch a sample to examine its grain structure under a microscope, looking for the fine, uniform grain of a proper forging and heat treatment.

A transparent supplier will be able to provide test reports and explain their testing frequency and procedures. This data is the objective proof that stands behind their quality claims.

Evaluating Supplier Support and Warranty Policies

The relationship with a parts supplier should not end when the invoice is paid. The post-sale support and warranty policy are a direct reflection of the manufacturer's confidence in their own product.

- Garantie: Read the warranty policy carefully. What does it cover, and for how long? Is it based on operating hours or a period of time? What is the process for making a claim? A clear, uitgebreid, and fair warranty is a sign of a manufacturer that stands behind their precision forged undercarriage parts. A vague or non-existent warranty is a major red flag.

- Technische ondersteuning: Can you speak to someone who understands the product technically? If you have a question about installation, or if you experience an unusual wear pattern, is there an expert available to provide guidance? Access to knowledgeable technical support can be just as valuable as the part itself, especially when diagnosing complex issues.

- Availability and Logistics: A great part is useless if you cannot get it when you need it. Evaluate the supplier's inventory levels and their logistical capabilities, especially for your region. Do they have distribution centers that can serve markets in Australia, Rusland, or Southeast Asia efficiently? A supplier with a strong global logistics network can significantly reduce your downtime when a critical part is needed.

Factor 5: Long-Term Value and Total Cost of Ownership (Totale eigendomskosten)

In de wereld van zware machines, the most dangerous number on a quote is often the lowest one. A procurement strategy focused solely on minimizing the initial purchase price of undercarriage parts is a recipe for long-term financial pain. A more sophisticated and ultimately more profitable approach is to evaluate the Total Cost of Ownership (Totale eigendomskosten). TCO is a financial estimate that helps buyers determine the direct and indirect costs of a product over its entire lifecycle. It reveals that the true cost of a component is far more than its sticker price.

Beyond the Initial Purchase Price

The initial cost of a set of precision forged undercarriage parts will almost certainly be higher than that of their cast counterparts. The more complex manufacturing process, higher quality raw materials, and extensive quality control all contribute to this higher upfront investment. Echter, this initial price is only one piece of a much larger puzzle. The TCO calculation forces us to consider all the other associated costs that a cheaper, inferior part will inevitably generate.

A TCO analysis for undercarriage parts should include:

- Initiële aankoopprijs: The cost of the components themselves.

- Arbeidskosten installatie: The cost of the mechanics' time to remove the old parts and install the new ones.

- Cost of Downtime: The revenue lost for every hour the machine is out of service.

- Verwachte levensduur: The number of operating hours the part is expected to last.

- Future Replacement Costs: The price of the next set of parts and the labor to install them.

When you factor in a longer lifespan, the cost-per-hour of a premium part often turns out to be significantly lower than that of a cheap one.

Calculating the Cost of Downtime

The cost of downtime is the most significant and often the most underestimated factor in the TCO equation. It is not a soft, abstract number; it is hard cash evaporating from the company's bottom line. How does one begin to quantify it?

Consider a 40-ton excavator working on a critical path of a construction project.

- Lost Revenue: If the machine generates, Bijvoorbeeld, $200 per hour in revenue for the company, every hour it sits idle is a direct loss of $200.

- Operator & Support Costs: The operator is likely still being paid, as are any support personnel (Bijv., truck drivers waiting for the excavator to load them). Let's say this is another $50 per uur.

- Project Penalties: Many large contracts have penalty clauses for delays. If the failure of this one machine delays the entire project, the costs can escalate into thousands or tens of thousands of dollars per day.

- Reputational Damage: Consistently failing to meet deadlines due to equipment breakdowns damages a company's reputation, making it harder to win future bids.

Let's imagine a cheap set of track chains fails after 2,500 uur, while a premium set of precision forged track chains lasts 4,000 uur. The cheap set might have saved $2,000 on the initial purchase. But it requires an extra replacement cycle within that 4,000-hour window. That extra cycle might involve 16 hours of labor ($1,200) en 16 hours of machine downtime ($3,200 in lost revenue alone). The total cost of that "saved" $2,000 is now an actual loss of $2,400 ($1,200 + $3,200 – $2,000), and that's before even considering project penalties. The premium part, despite its higher initial cost, delivers a far superior return on investment.

The Symbiotic Relationship with Maintenance Practices

The full value of high-quality precision forged undercarriage parts can only be realized when paired with diligent maintenance practices. The two are intertwined. A premium component can tolerate a degree of neglect better than a cheap one, but its lifespan will still be shortened. Omgekeerd, even the best maintenance cannot save a part made from inferior materials.

Key maintenance practices that maximize the life of your investment include:

- Regelmatig schoonmaken: Periodically cleaning out mud, rotsen, and debris from the undercarriage. Packed material increases weight, strain, and abrasive wear.

- Proper Track Tension: A track that is too tight causes a massive increase in friction and wear on all components. A track that is too loose can cause the machine to "de-track" and cause significant damage. Track tension should be checked and adjusted regularly according to the OEM specifications and the current working conditions.

- Regelmatige inspecties: Visually inspecting the undercarriage daily for loose bolts, leaking seals, or unusual wear patterns. Using ultrasonic tools to measure the wear on components like track links and rollers allows for proactive planning of replacements, turning unexpected downtime into scheduled maintenance.

- Smart Operation: Training operators to minimize high-speed reverse travel, avoid unnecessarily sharp turns, and work up and down slopes rather than across them can significantly reduce undercarriage wear.

Investing in premium parts and investing in good maintenance are two sides of the same coin. Both are essential components of a strategy aimed at maximizing machine availability and profitability.

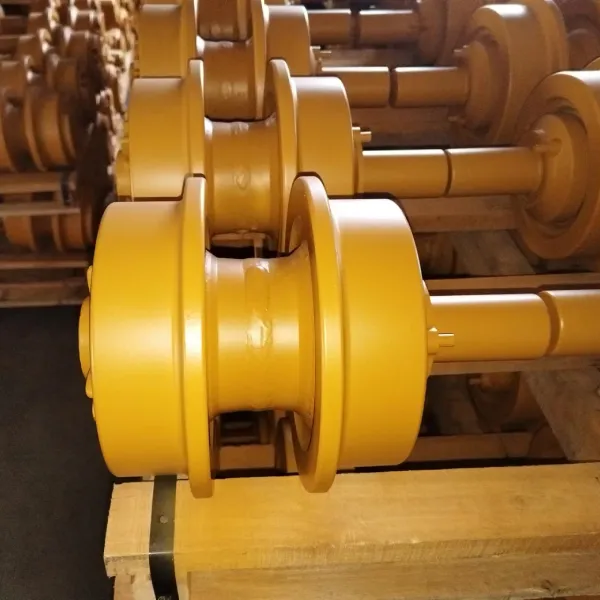

A Deeper Examination of Key Undercarriage Components

While we have discussed the undercarriage as a system, it is composed of several distinct components, each with its own unique role and wear characteristics. Understanding these individual parts helps in diagnosing wear and making informed replacement choices.

| Onderdeel | Primaire functie | Common Wear Patterns | Forging Benefits |

|---|---|---|---|

| Volg keten / Link Assembly | Forms the flexible "belt" that the machine runs on; connects the track shoes. | Internal pin and bushing wear; link rail wear from rollers. | Superior fatigue resistance to withstand constant flexing and tensile loads. |

| Looprollen (Onderste rollen) | Support the machine's weight on the track chain. | Flange wear from turning; tread wear from contact with the links. | High surface hardness to resist wear; core toughness to resist impact from rough ground. |

| Draagrollen (Bovenste rollen) | Support the weight of the track chain on its return path. | Tread wear from the track chain. | Excellent sealing is critical; forged body provides a strong, stable housing for bearings and seals. |

| Tandwiel | Engages with the track bushings to drive the track. | Tooth wear, "hooking" of teeth as they wear. | Exceptional hardness on tooth contact surfaces to resist wear from bushing engagement. |

| Idler | Guides the track at the front of the undercarriage and is used to adjust track tension. | Tread and flange wear, similar to rollers. | Large, complex geometry benefits greatly from the strength and integrity of the forging process. |

Rupskettingen: This is the skeleton of the track. The precision with which the pins and bushings are manufactured and heat-treated determines how long the chain maintains its correct pitch (de afstand tussen de pinnen). As pins and bushings wear internally, the pitch elongates, which accelerates wear on the sprocket. The links themselves must endure immense tensile forces and abrasive wear, making the refined grain structure of a forged link indispensable.

Rollen en meelopers: These components live a life of constant compression and friction. Their ability to roll smoothly and resist wear is a function of their surface hardness and the quality of their internal bearings and seals. A leak in a roller seal allows abrasive grit to enter and oil to escape, leading to rapid and complete failure. The robust, dimensionally accurate body of a forged roller provides the best possible housing for these critical seals.

Tandwiel: The sprocket transfers the power from the final drive to the track chain. The tips of the sprocket teeth experience extremely high contact stress as they engage the track bushings. Smeden, followed by precise induction hardening of the teeth, is the only way to create a sprocket that can withstand these forces without premature wear or tooth breakage.

By understanding the specific job of each part, one can better appreciate why a generic, one-size-fits-all approach to material and manufacturing is inadequate. Each component requires a tailored solution, and the precision forging process provides the flexibility and control to deliver that tailored solution with unparalleled strength and reliability.

Veelgestelde vragen (Veelgestelde vragen)

What is the most significant difference between precision forged and cast undercarriage parts? The primary difference lies in the internal grain structure of the metal. Forging kneads and aligns the steel's grain to follow the shape of the part, creating a dense, continuous structure that is significantly stronger and more resistant to shock and fatigue. Casting involves pouring molten metal into a mold, resulting in a random grain structure that can contain microscopic voids, making it more brittle and prone to unexpected failure under stress.

How does my working environment affect which undercarriage parts I should choose? Your environment is a critical factor. For highly abrasive conditions like sand or fine gravel, you need parts with maximum surface hardness to resist wear. For high-impact work like in a rock quarry, you need parts with superior core toughness to absorb shock without cracking. For extreme cold, you need parts made from specific steel alloys that resist becoming brittle at low temperatures. A good supplier will help you match the part's engineering to your specific application.

Can I mix and match undercarriage components from different manufacturers? While it is sometimes possible, het wordt over het algemeen niet aanbevolen. Different manufacturers may have slight variations in dimensional tolerances, material specifications, and hardness profiles. Mismatched components can lead to improper fit and accelerated wear on the entire system. Bijvoorbeeld, a new, correctly pitched track chain running on a worn sprocket will cause the new chain to wear out much faster. For optimal performance and lifespan, it is best to use a complete, matched system from a single, high-quality manufacturer.

Is a higher price for precision forged parts always justified? When evaluated through the lens of Total Cost of Ownership (Totale eigendomskosten), the higher initial price is almost always justified. The extended lifespan and superior reliability of precision forged parts lead to fewer replacement cycles, reduced labor costs, en, het allerbelangrijkste, a dramatic reduction in costly machine downtime. The small premium paid upfront is an investment that yields significant returns by keeping your machinery productive and profitable.

How can I verify the quality of a potential supplier's parts? Look for objective evidence. Ask for quality certifications like ISO 9001. Inquire about their material sourcing and ask to see chemical analysis and mechanical testing reports for their steel. Discuss their heat treatment processes. A reputable manufacturer will be transparent and able to provide detailed technical data to substantiate their quality claims. Eindelijk, consider their warranty and level of technical support, as this reflects their confidence in their own product.

When should I plan to replace my undercarriage? Replacement should be based on measured wear, not just on hours of use. Using specialized tools to measure the wear on track pins, bussen, link rails, and roller flanges allows you to track the wear rate and predict when components will reach the end of their service life. This proactive approach allows you to schedule maintenance before a failure occurs, turning a costly, unexpected breakdown into a planned, efficient service event.

What is the role of heat treatment in the quality of a track shoe? Heat treatment is vital for a track shoe, which needs a difficult combination of properties. The main body of the shoe needs to be tough to resist bending and cracking as it moves over uneven ground. Echter, the grousers (the raised bars that provide traction) need to be very hard to resist abrasive wear. A process called "through-hardening" followed by careful tempering is used to achieve the necessary core toughness, ensuring the shoe can withstand the immense stresses placed upon it.

Conclusie

The selection of undercarriage parts for heavy machinery is a decision with far-reaching consequences, impacting everything from daily operational efficiency to the long-term profitability of a business. A superficial approach, guided only by the initial purchase price, overlooks the complex interplay of forces, materialen, and environments that define the working life of these components. It is a path that often leads to increased downtime, spiraling maintenance costs, and compromised project timelines.

A more enlightened path involves a deeper engagement with the principles of material science, manufacturing processes, en toepassingsspecifieke engineering. By understanding the metallurgical advantages conferred by specific steel alloys, appreciating the microstructural superiority of the precision forging process, and insisting on designs tailored to the unique challenges of the operating environment, one transforms a simple purchase into a strategic investment. This approach, centered on the concept of Total Cost of Ownership, recognizes that true value lies not in the initial saving but in the extended lifespan, enhanced reliability, and sustained performance that high-quality components deliver. Uiteindelijk, choosing precision forged undercarriage parts is an affirmation of a commitment to quality, a strategy for risk mitigation, and a foundational step in building a resilient and successful heavy equipment operation.

Referenties

American Society for Metals. (1988). Forging and related forming processes. In Metals Handbook: Vol. 14. Forming and Forging (9th ed.). ASM International.

Boyer, H. E. (Ed.). (1987). Atlas of heat treatment diagrams. ASM International.

Davis, J. R. (Ed.). (2001). Alloying: Understanding the basics. ASM International. https://doi.org/10.31399/asm.tb.autb.9781627082859

Khurmi, R. S., & Gupta, J. K. (2005). A textbook of machine design. Eurasia Publishing House.

Lange, K. (Ed.). (1985). Handbook of metal forming. McGraw-Hill.

SMI. (2021). Forging basics: The forging process. Forging Industry Association. Retrieved from

Totten, G. E. (2006). Steel heat treatment: Metallurgy and technologies. CRC Press. https://doi.org/10.1201/9781420006463

Verma, J. P., & Kumar, S. (2019). A review on effect of alloying elements on stainless steel. Materials Today: Proceedings, 18, 466-473.